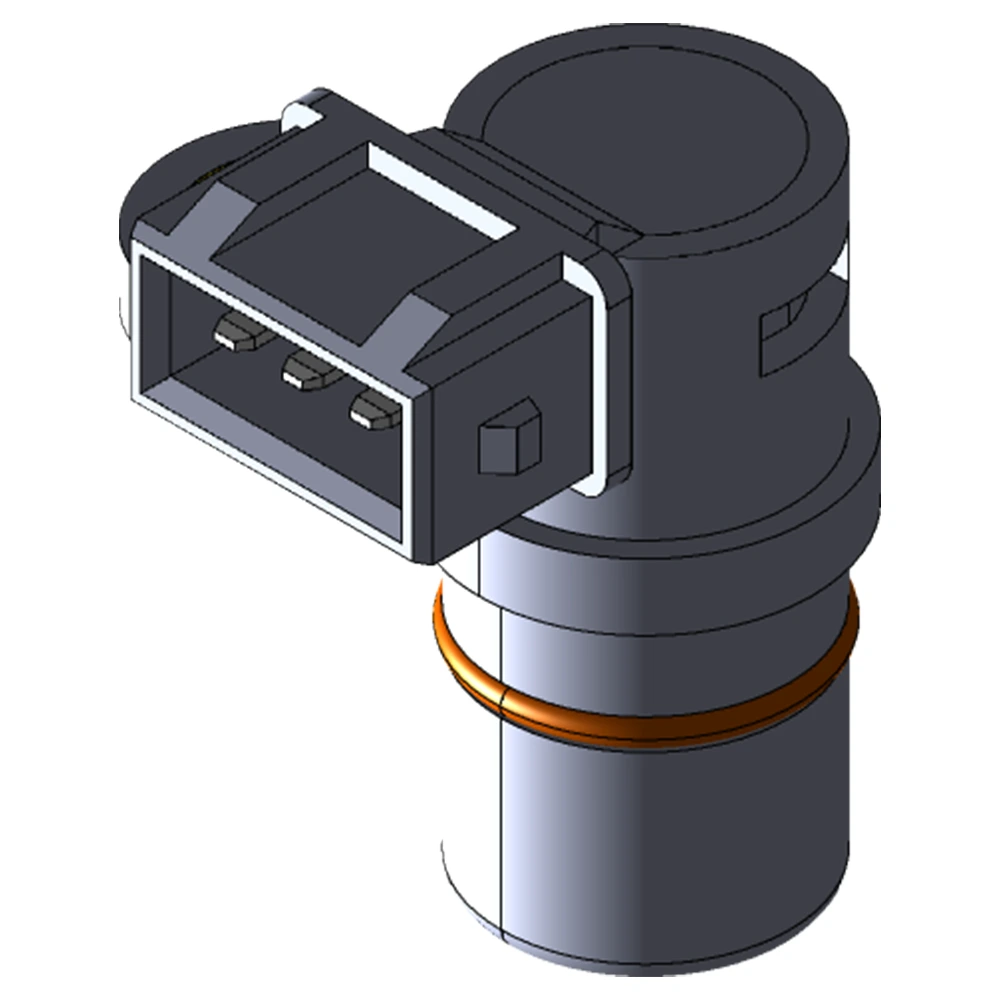

Coolant Temperature Sensor- How it work & failed?

The coolant temperature sensor is also called ECT. This sensor measures the temperature of your engine. The information collected affects fuel delivery, ignition timing and engine performance.

The ECT is usually attached to the engine block or cylinder head. This is the hottest coolant flow. In some cases, more than one coolant temperature sensor may be installed. They are placed in different places.

The sensor is partially submerged in coolant. It sends the collected data to the engine computer. This lets your car know if it’s running too hot or too cold.

How coolant temperature sensor work?

An engine temperature sensor is a type of sensor that changes its resistance with temperature. Many critical engine functions such as air-fuel ratio, fuel injection timing, ignition timing, etc. depend on engine temperature. This is because a cold engine needs a rich mixture of air and fuel; while an engine operating at optimum operating temperature requires a lean mixture.

The engine temperature sensor informs the engine ECU of current and continuous changes in engine temperature. The ECU in turn regulates and regulates the amount of fuel and ignition timing. The data from the engine temperature sensor provides the engine temperature gauge readings on the dashboard. Based on this data, the ECU also controls additional functions such as turning the engine cooling fan on/off.

Why coolant temperature sensor failed?

Coolant temperature sensors are basically made of NTC thermistors. What the trip computer receives is the resistance value returned by NTC. So, it doesn’t matter if by “broken” you mean a short circuit or an open circuit. For the trip computer, the received signal is either 0 resistance or infinite resistance;

In both cases, the trip computer will determine that the temperature sensor is faulty. The fault light is always on or accompanied by an alarm sound, and the intake air volume and fuel injection volume of the intake valve are forcibly reduced, and the formal speed of the engine is reduced. Avoid unnecessary damage and wear of the vehicle caused by overheating of the engine;

Of course, the on-board computer in some cars is too simple and does not have the function of automatic protection of speed regulation. At this time, only the fault light is always on or accompanied by an alarm sound, and the car can be used normally.

Common fault codes

Common fault codes and causes include:

- P0115: Engine Coolant Temperature (ECT) Circuit Malfunction

- P0116: Engine Coolant Temperature Circuit Range/Performance

- P0117: Engine Coolant Temperature Circuit Low Input

- P0118: Engine Coolant Temperature Circuit High Input

- P0119: Engine Coolant Temperature Circuit Intermittent

Symptoms of a faulty coolant temperature sensor?

A faulty coolant temperature sensor can manifest itself in different ways through the fault detection of the control unit and the resulting emergency program strategy.

Common symptoms are:

- Higher idle speed

- Black Smoke From Exhaust

- Increase in fuel consumption

- Bad start behavior

- Engine Overheating

In addition, there may be problems with the exhaust gas test cycle due to increased CO values or a gap in the lambda control. The following entries can be stored in the fault memory of the control unit:

- Short in frame wiring or sensor short

- Positive wiring failure or breakage

- Unaffected signal changes (signal jump)

- The engine does not reach the minimum coolant temperature

The latter error code can also occur if the coolant thermostat is faulty.

Troubleshooting a faulty coolant temperature sensor

Troubleshooting:

- Read the error memory

- Check sensor wiring, connector, and sensor electrical connections for proper connections, breaks, and corrosion.

Checks are carried out using the multimeter

- The internal resistance of the sensor is determined. Durability depends on temperature. When the engine is cold it has high resistance and when the engine is hot it has low resistance.

Depending on the manufacturer:

25°C 2.0 – 6 KOhm or 80°C approx. 300 Ohm

Please note the special reference value specifications.

- Check the control wiring by checking for continuity and a short at each control connector wire on the frame.

- Connect an ohmmeter between the temperature sensor connector and the removed control unit connector. Check value: about 0 Ohm (the circuit diagram is necessary to determine the pin of the control unit).

- Check the corresponding connector of the sensor connector against ground using an ohmmeter with the control unit connector removed. Control value: > 30 MOhm.

- Check the supply voltage of the removed sensor connector using a voltmeter. This is done by connecting the control unit and turning on the ignition. Control value: about 5V. If the voltage value is not reached, the control unit voltage and ground supply must be checked according to the circuit diagram. If they are OK, a fault in the control unit is suspected.

How to replace a faulty coolant temperature sensor?

- Disconnect the battery after the vehicle and engine have completely cooled.

- Remove the plastic covers of the engine.

- The cooling system is partially drained, if necessary, the coolant is flushed.

- Disconnect the electrical sensor and replace it.

- Check the connection systems to make sure they are not damaged.

- Return the parts according to their positions to ensure their safety and proper operation.

Get Full Support

MOOCAR — as a leading exporter, we are continually developing breakthrough sensing and actuating solutions to help optimize emissions control, fuel economy, and drivability. In addition to the above parts, we offer full support of data, market information.