DPF sensor - How it work & failed

The Diesel Particulate Filter (DPF) differential pressure sensor measures exhaust gas back pressure and signals when the Powertrain Control Module (PCM) should initiate a regeneration process to clean the filter of diesel particulate matter or soot. The DPF differential pressure sensor plays an important role in ensuring the proper functioning of the DPF. A clogged DPF is not only an expensive repair, it can also have disastrous consequences for a diesel engine. To understand how the DPF pressure sensor works, why it fails, and then how to replace it, let’s briefly discuss the DPF.

What is the DPF

As strict regulations to reduce emissions increase, diesel engines use the EGR valve to reduce NOx emissions and the DPF to remove soot from diesel exhaust. The wall flow design of the DPF, installed near the beginning of the exhaust system, captures an average of 85% of soot from the engine, and can even achieve 100% efficiency under certain conditions. To prevent filter clogging, the engine starts the regeneration process by injecting fuel into the exhaust system. The injected fuel raises the temperature of the DPF to 600°C (or 1112°F) so that the obstructing soot can burn off, turning it into ash. On some vehicles, the PCM relies on data from the DPF pressure sensor to initiate the DPF regeneration process.

How DPF sensor work?

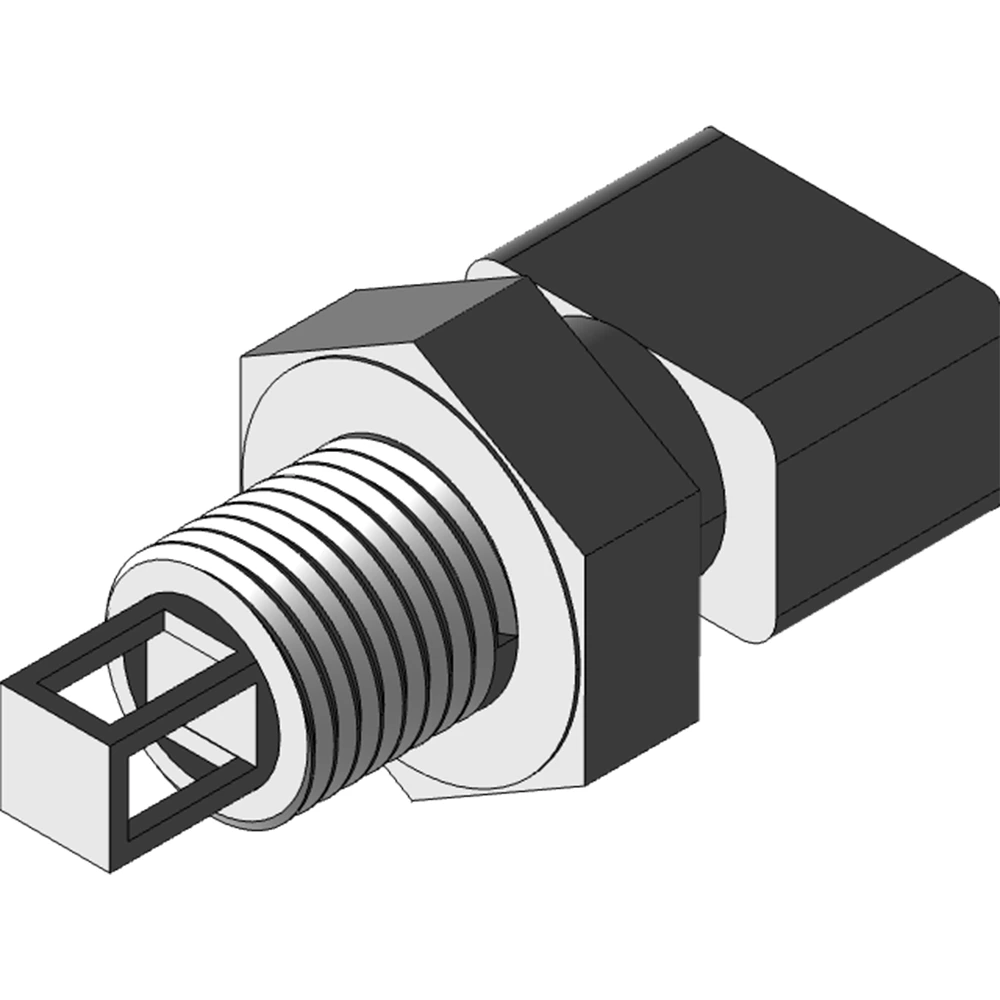

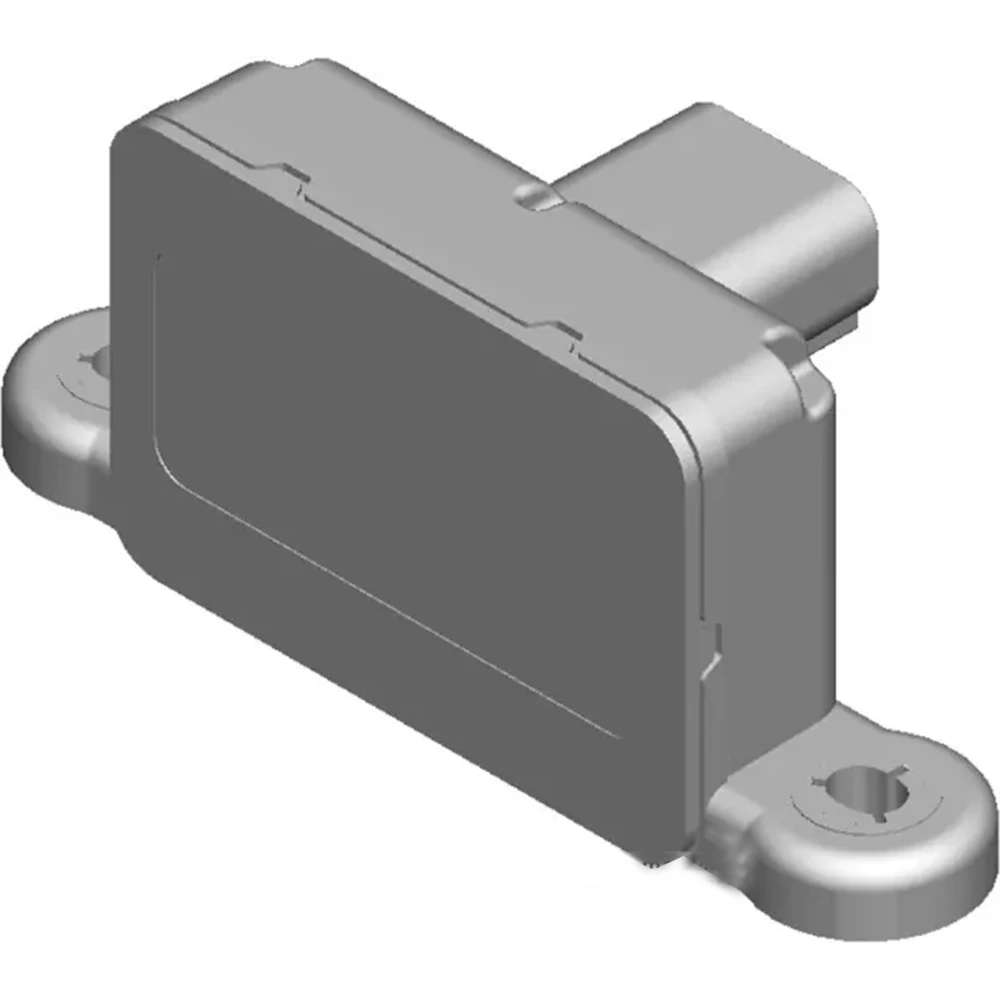

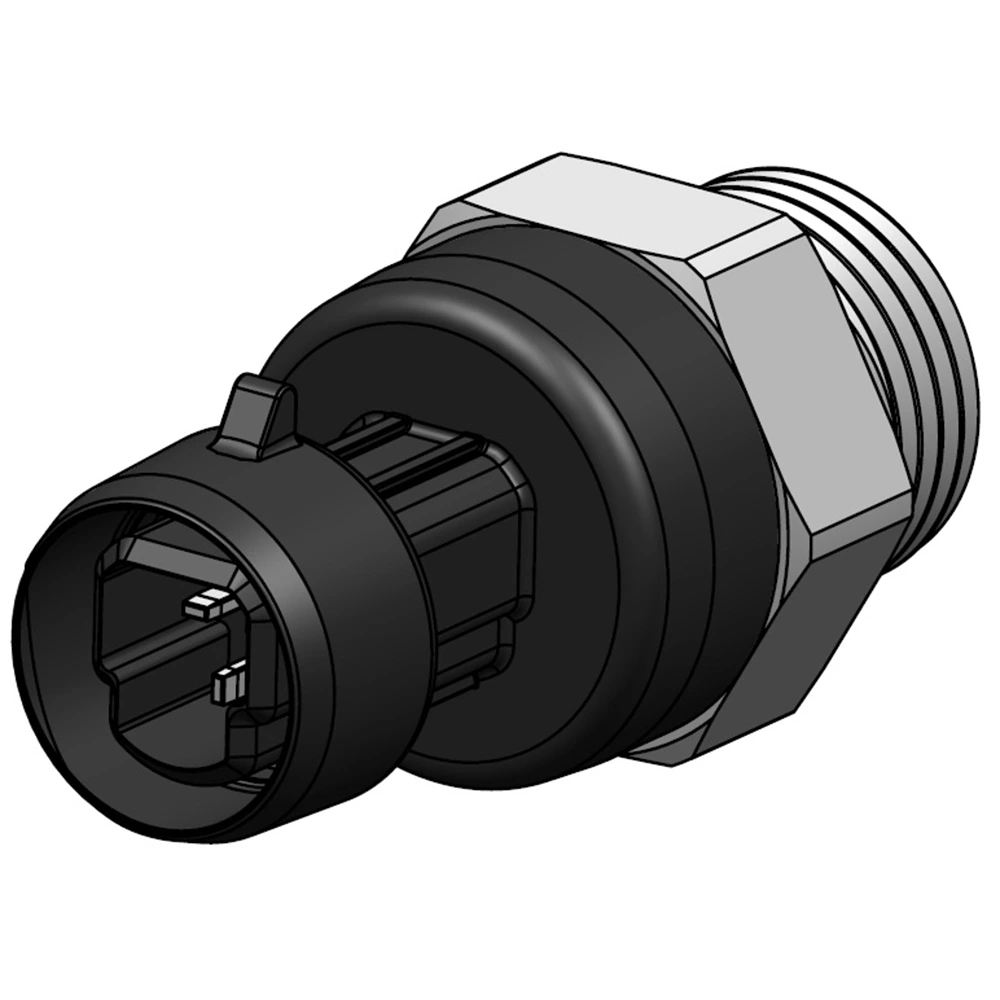

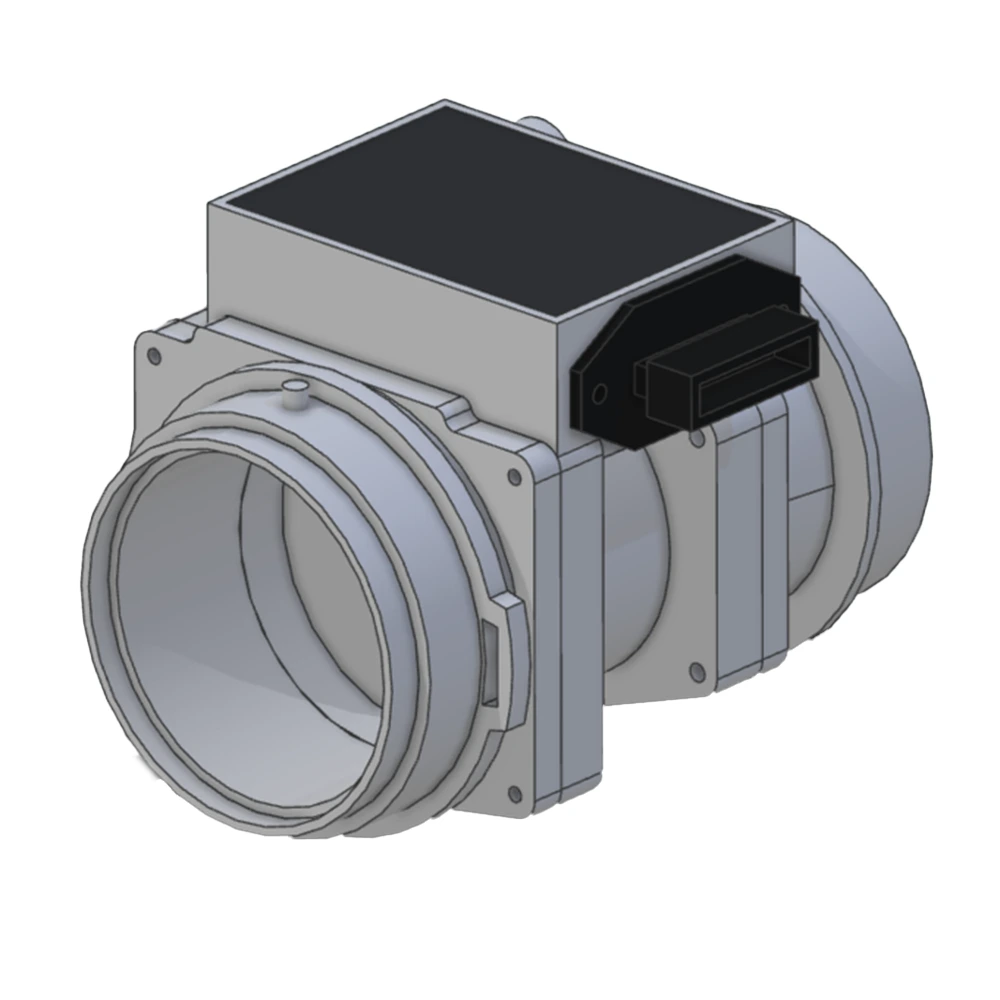

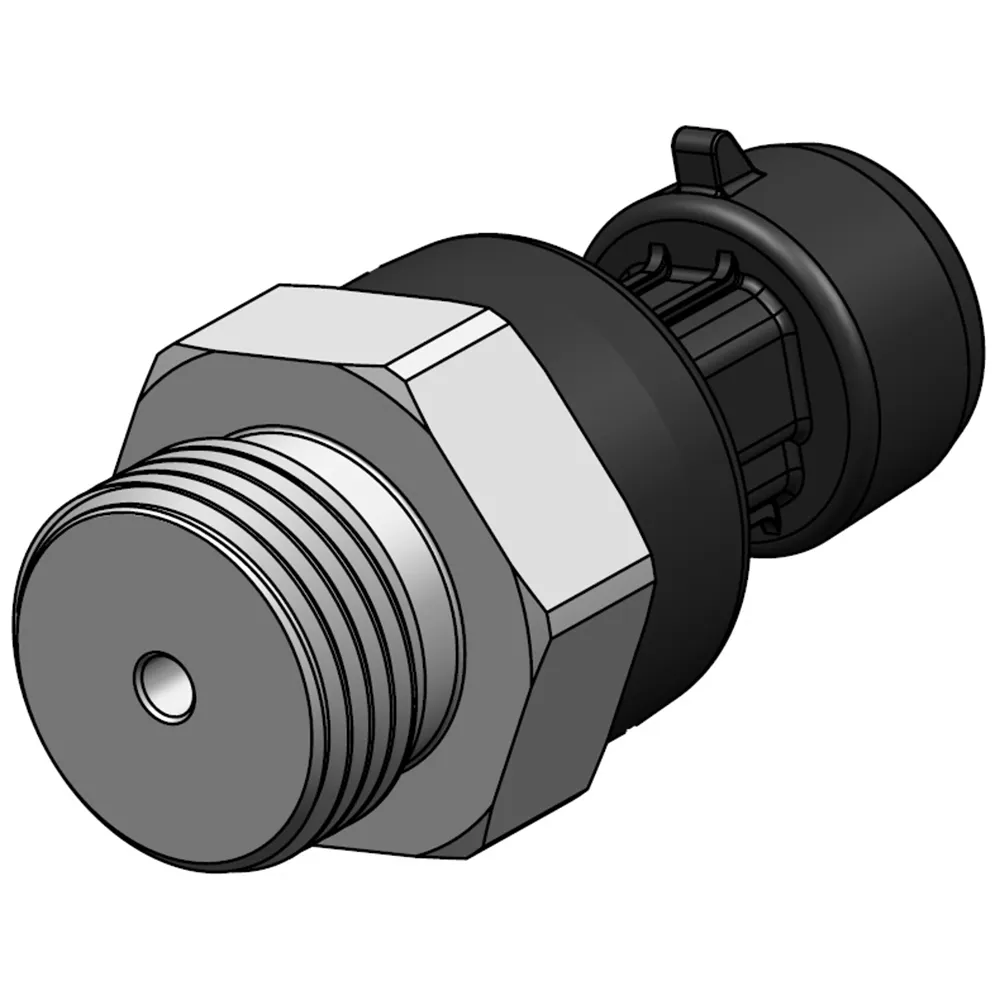

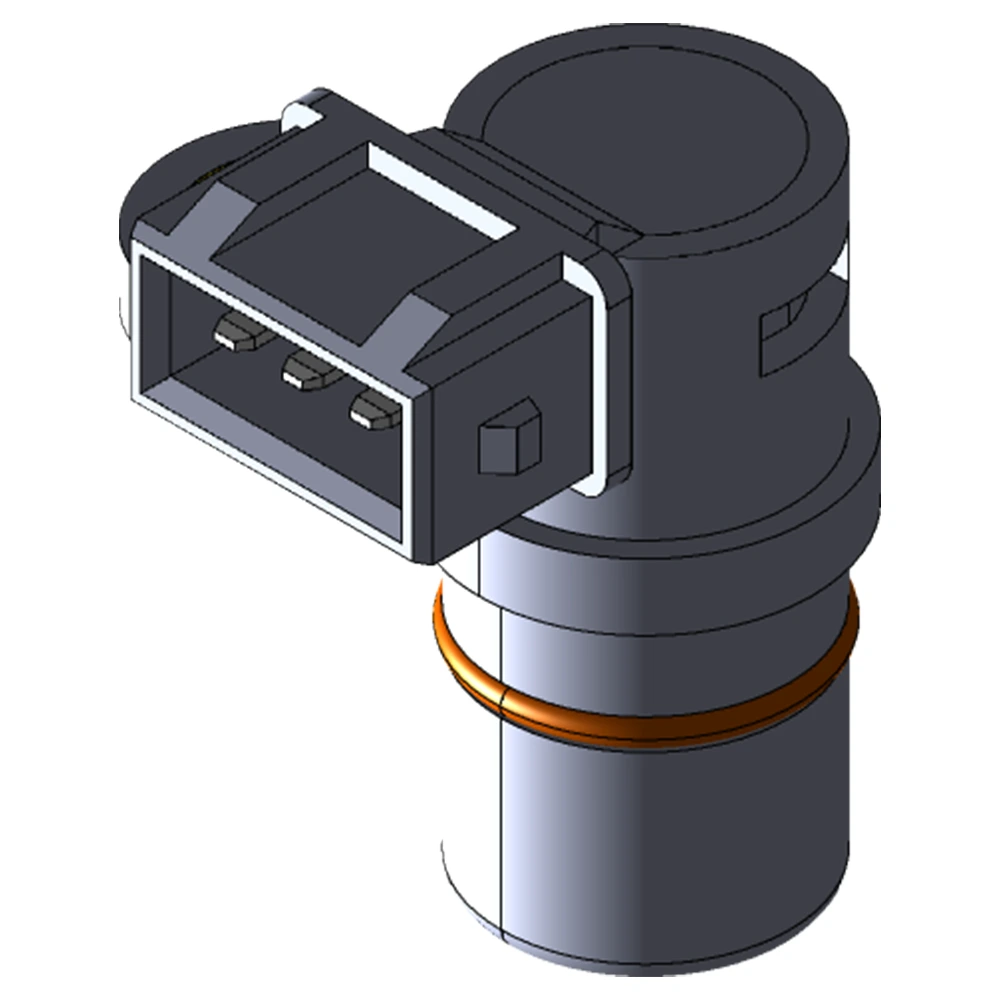

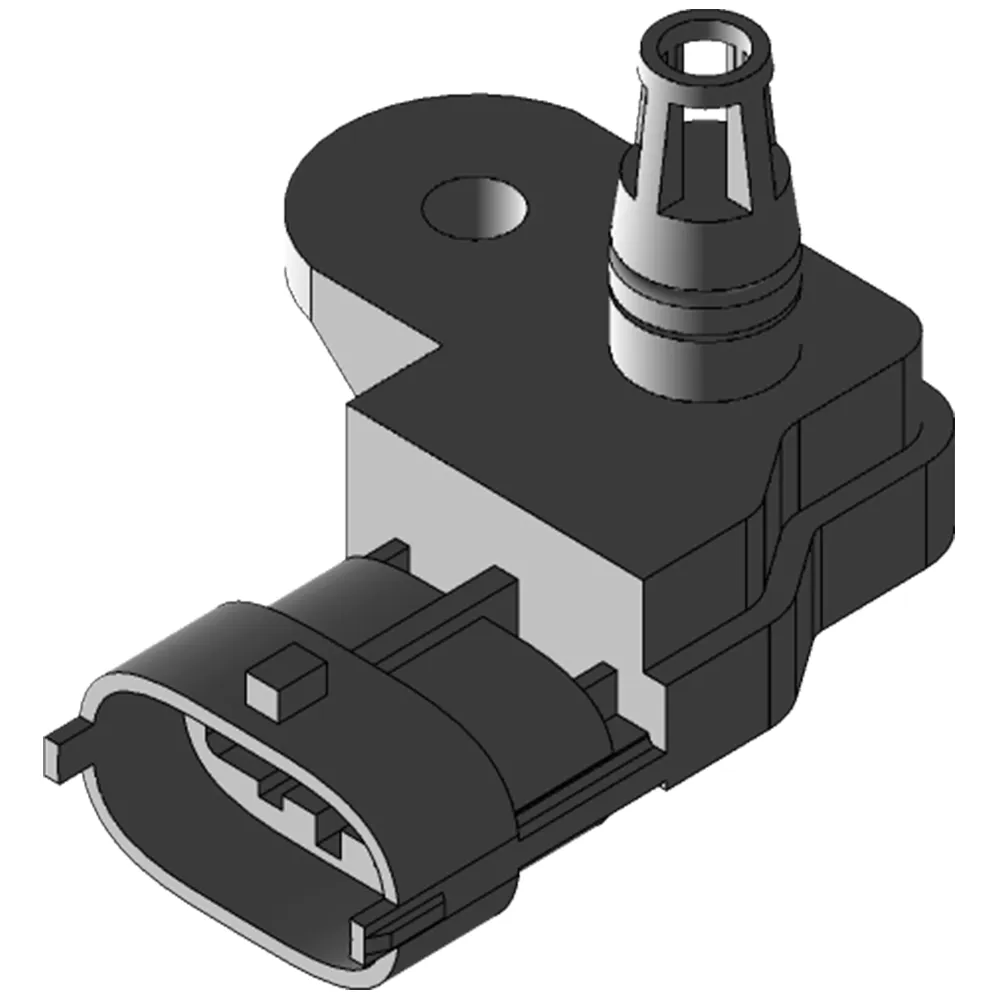

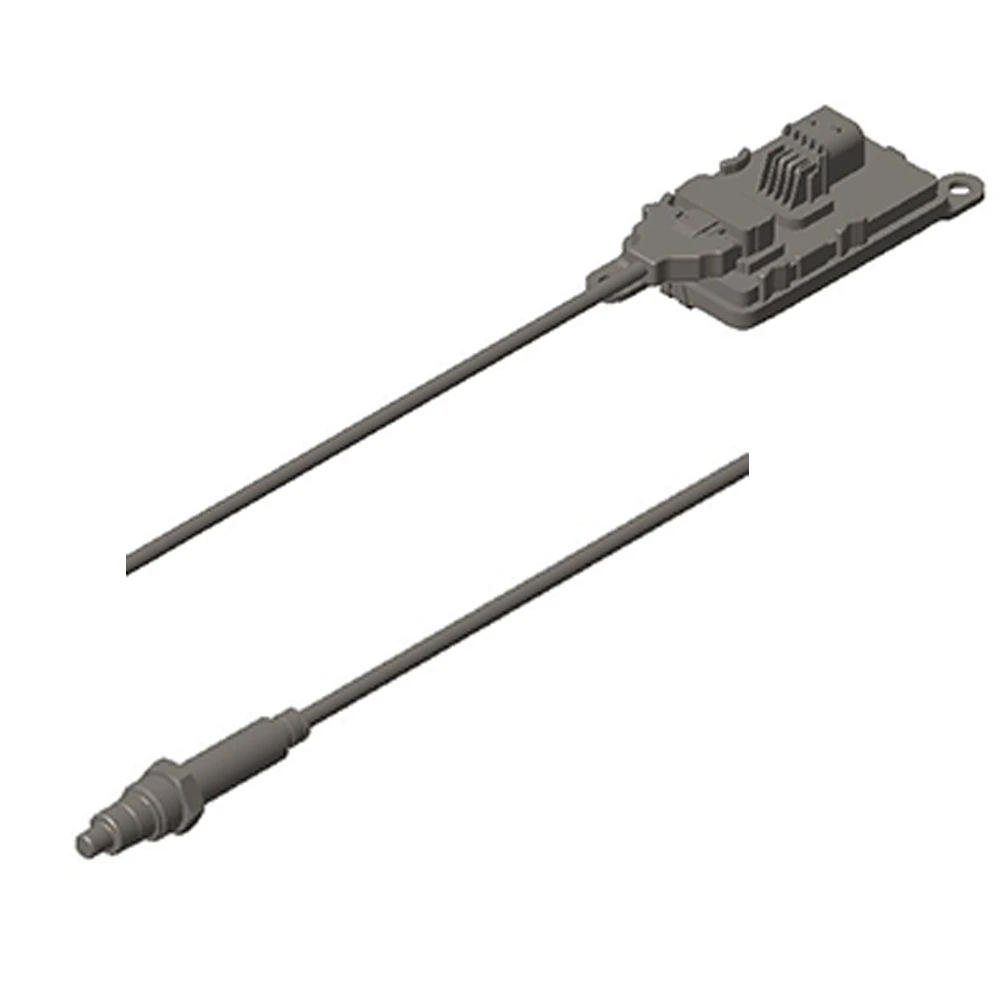

The DPF pressure sensor is usually installed in the engine compartment to protect it from heat. The sensor connects to the engine control unit (ECU) with an electrical connector and connects to the DPF via two silicon hoses. One hose connects before (upstream) the DPF, the other connects after (downstream) the filter. By measuring and comparing the difference in exhaust gas pressure before and after the filter, the sensor can estimate the amount of DPM trapped in the filter and signal the PCM to start the DPF regeneration process.

Why DPF sensor failed?

As with any electrical sensor in an engine, ECU wiring can be damaged by heavy vibration or crack and melt due to extreme heat. And like the DPF, the sensor hoses can become clogged with exhaust soot. If diesel particles block one or both of the sensor’s airways, the sensor can no longer accurately detect pressure changes, which can cause catastrophic damage to the DPF and ultimately the engine.

Common fault codes

- P2452: Diesel Particulate Filter Pressure Sensor ‘A’ Circuit

- P2453: Diesel Particulate Filter Pressure Sensor A Circuit Range/Performance

- P2454: Diesel Particulate Filter Pressure Sensor “A” Circuit Low

- P2455: Diesel Particulate Filter Pressure Sensor A Circuit High

Note: An exhaust leak can cause these codes to set.

What to pay attention to in the case of a failed ABS sensor?

If the DPF pressure sensor stops signaling the PCM to regenerate, the DPF can be completely blocked and ruined by contaminants. Here are some signs that the DPF sensor is not recovering properly due to a DPF sensor failure:

- Poor engine performance

- Poor fuel economy

- High engine temperatures

- High transfer temperatures

- Increase in black smoke (soot) from exhaust gas

- Check engine lights

If the DPF is not working, the exhaust cannot be fully cleaned because the back pressure pushes the exhaust back into the combustion chamber, causing the DPM or soot to mix with the engine oil. Soot is abrasive and when mixed with oil causes premature wear of engine bearings. Even during regeneration, the fuel coming out of the exhaust gas is only partially burned. Residual fuel then washes away the protective oil film from the engine’s internal components and causes catastrophic failure.

The DPF pressure sensor is important to the longevity of the DPF and if the DPF becomes completely obstructed, the regeneration process will not fix it. It must either be removed and professionally cleaned or replaced, both options costing thousands of dollars on average. Much more than the cost of diagnosing and replacing a faulty sensor before it’s too late.

Troubleshooting a DPF sensor

When troubleshooting engine sensors, it is recommended to first look for signs of visible damage. Check all connections, starting with the sensor’s electrical connector, for damage such as cracking or melting. Damaged wires must be replaced.

Then check the hoses connected to the sensor. Again, look for damage such as cracking or melting. If the hoses are damaged, they will need to be replaced and probably re-routed so they don’t do the same damage again. If the hoses appear to be in good physical condition, check for blockages or blockages. If the hoses become clogged, the hoses must be cleaned or replaced.

- If everything passes the physical check, you can test the DPF pressure sensor using a 20V multimeter and a pressure gauge.

- With the battery on and the engine off, connect the ground of the multimeter to the negative battery terminal and run a quick plausibility test checking the battery voltage. It should be around 12.6 volts.

- Refer to the manufacturer’s service manual for signal, ground, and 5-volt reference wire identification and return probe.

- Turn the ignition switch on without starting the engine. The multimeter should (typically) show a voltage between 4.5V and 5V for the 5V reference, a steady 0V for the ground wire, and 0.5V to 4.5V for the signal wire. See OEM Factory Services information for exact specifications for your vehicle

- Start the engine with the signal wire.

- Start the engine and notice the voltage change. If not, test the connecting hoses with a pressure gauge.

- With the engine running, remove the hoses from the sensor.

- Measure the pressure in both hoses using a pressure gauge. Use an exhaust back pressure gauge that measures 0-15 PSI to ensure sufficient accuracy.

- Check the signal voltage again. The voltage should read between the pressure values of the number of hoses. For example, if the rear hose reads half PSI and the front hose reads 1 PSI, the voltage on the signal wire should read somewhere in the middle, around 0.8 volts.

If the voltage is significantly different or the pressure values do not match the voltage reading, the DPF differential pressure sensor is faulty and needs to be replaced.

How to replace a faulty DPF differential pressure sensor

Before replacing a faulty DPF differential pressure sensor, refer to the manufacturer’s service manual for specific instructions. If you need more room to get under the vehicle, secure the rear wheel and place jack stands to support the vehicle.

- Locate the DPF differential pressure sensor mounted at the rear of the engine compartment.

- Disconnect the electrical plug.

- Remove the screws or bolts (sometimes a Torx bolt) holding the sensor in place.

- Carefully move the sensor away to remove the screw clamps holding the hoses.

- Before disconnecting the sensor, note which side fits which hose.

- Compare new and old sensors.

- Reconnect the hoses in the same position to the new sensor.

- Attach the hose clamps.

- Reinstall the screws or bolts that hold the sensor in place.

- Connect the electrical connector to the new sensor.

- Check all connections to make sure everything is secure.

Important Note: After installing a new DPF pressure sensor, the sensor offset must be programmed into the ECU.

Get Full Support

MOOCAR — as a leading exporter, we are continually developing breakthrough sensing and actuating solutions to help optimize emissions control, fuel economy, and drivability. In addition to the above parts, we offer full support of data, market information.