1. Common NOₓ Sensor Fault Codes and Their Implications

NOₓ sensors generate standardized OBD-II codes when irregularities occur. Key DTCs include:

- P2A00: “Reductant Flow Below Minimum”—indicates incorrect urea dosing, often tied to upstream sensor drift.

- P2A01: “Reductant Flow Above Maximum”—signals excessive AdBlue injection, possibly due to false high readings from a contaminated sensor.

- P2A02/P2A03: “NOₓ Sensor Circuit Low/High”—electrical circuit faults or sensor element failure.

Intermittent codes may stem from connector corrosion triggered by road salt ingress; a quick moisture barrier application can reduce faults by 30% in winter.

2. Systematic Diagnostic Workflow

A structured approach minimizes guesswork:

- Scan and Document Codes: Use a professional-grade scan tool to read DTCs, freeze-frame data, and pending codes.

- Perform Live Data Tests: Monitor NOₓ readings at idle, under load, and during SCR active operation. Ensure sensors warm up to operational temperature (approx. 600 °C) before trusting values.

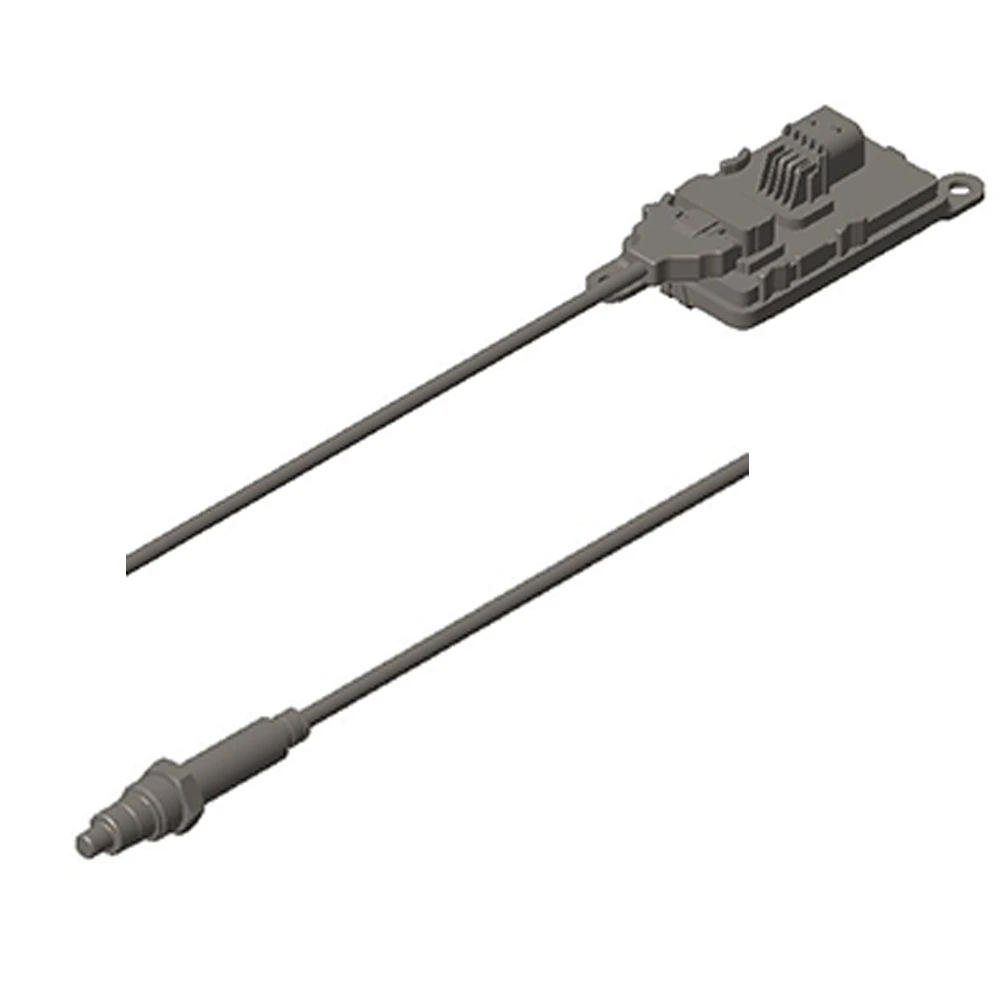

- Inspect Wiring and Connectors: Check for pin corrosion, chafing, or loose fits along the harness. Use dielectric grease on multi-pin connectors to enhance electrical integrity.

- Swap and Isolate: On fleets with multiple vehicles, swap suspect sensors with known-good units to isolate whether the issue lies in the sensor or vehicle wiring/ECU.

Implementing a “flo data” graph overlay—plotting upstream vs downstream NOₓ in real time—can visually pinpoint sensor drift versus catalyst degradation.

3. Cleaning, Calibration, and Recalibration Techniques

Effective maintenance extends sensor life:

- Cleaning Optical Sensors: Gently apply compressed air at 20 psi through the sensor tip to dislodge soot without damaging optical windows.

- Electrochemical Sensor Regeneration: Encourage passive regeneration by elevating DPF temperature above 600 °C, which burns away soot lodged on sensor membranes.

- Recalibration Protocols: Utilize manufacturer-specific calibration kits or handheld OBD calibrators to reset sensor baselines, especially after cleaning or part replacement.

Introducing a brief rich-burn cycle—injecting slightly extra fuel—raises exhaust temperature rapidly, aiding both sensor and DPF cleaning in under five minutes without service disassembly.

4. Mejores prácticas de mantenimiento preventivo

Proactive measures reduce downtime and extend component life:

- Scheduled Sensor Inspection: Align NOₓ sensor checks with major service intervals (e.g., every 50,000 miles) rather than waiting for faults.

- Environmental Protection: Fit external conduit and heat shields to protect sensors from road debris and thermal shock on off-road applications.

- Firmware Updates: Leverage OBD-II or manufacturer software to apply firmware patches that refine drift compensation algorithms and self-test routines.

Deploying over-the-air (OTA) firmware updates via telematics can reduce field service visits by up to 25%, ensuring sensors remain optimized for evolving fuel formulations and driving cycles.

5. Knowing When to Replace Your NOₓ Sensor

Despite best efforts, sensors reach end-of-life:

- Persistent DTCs: Codes return immediately after clearing and cleanup—strong indicator of irreversible sensor degradation.

- Sluggish Response: Measured response time exceeds manufacturer spec (>1 second for electrochemical units), slowing SCR feedback loops.

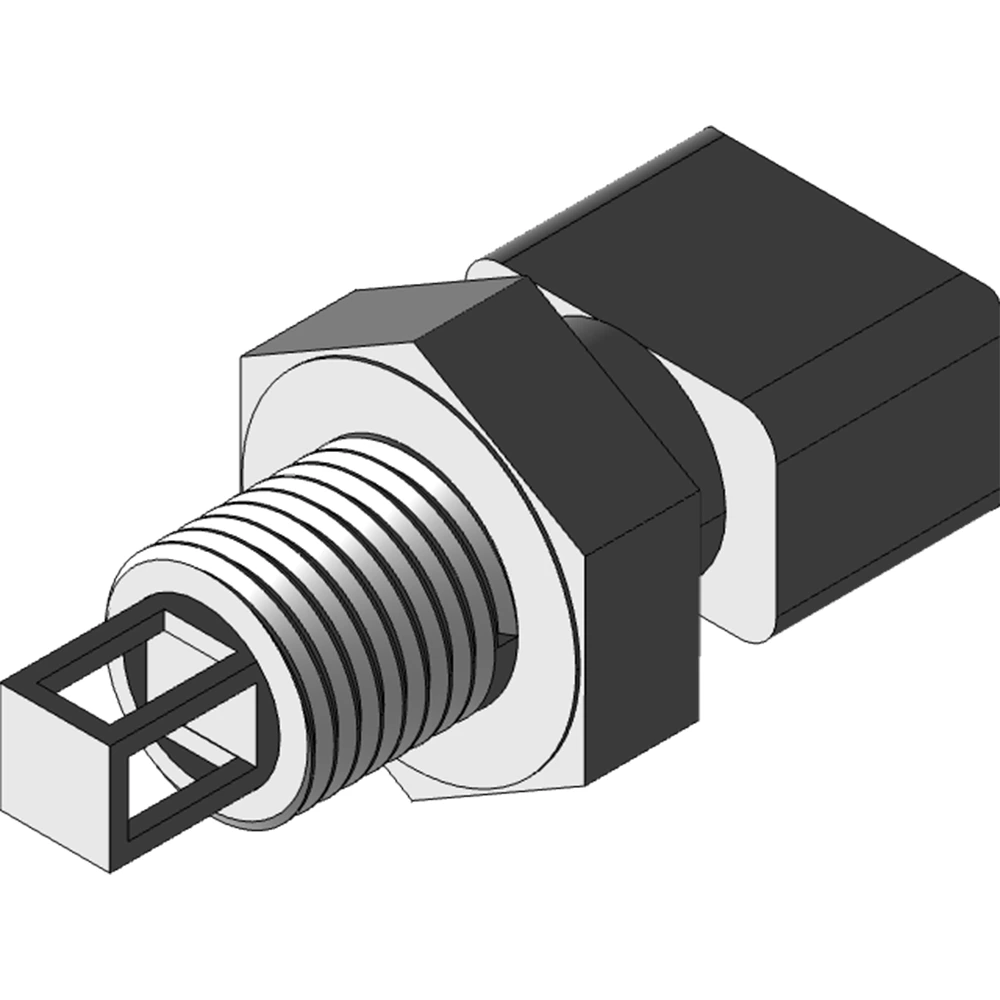

- Physical Damage: Cracked housing, melted connector plastic, or visible electrode corrosion.

- Failed Self-Test: ECU logs show sensor self-diagnosis errors in multiple cycles.

Maintaining a log of sensor performance metrics—tracking baseline drift and response time—lets technicians predict replacements before roadside failures, boosting fleet reliability.

Troubleshooting and maintaining NOₓ sensors require a blend of electronic diagnostics, mechanical care, and strategic calibration. By following structured workflows, employing creative maintenance techniques, and recognizing replacement triggers early, technicians can ensure emission systems remain accurate, compliant, and cost-effective.