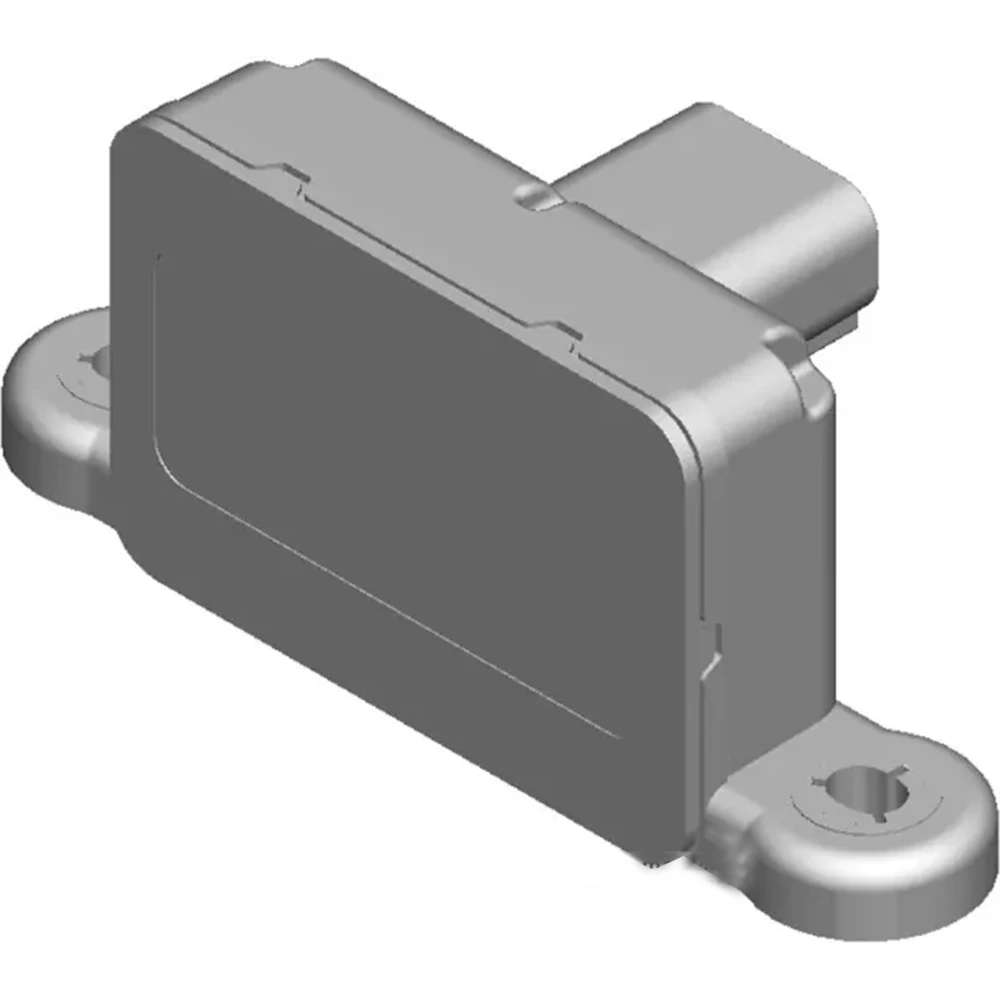

In modern automotive control systems, steering angle sensors (SAS) are more than just rotational encoders — they are real-time inputs to vehicle dynamics and safety-critical systems. As a manufacturing engineer in automotive electronics, I’ve witnessed firsthand how precise angle detection contributes directly to features like electronic stability control, lane keeping assist, and active steering systems. This article provides a practical overview of what these sensors are, how they work, and why they matter.

What Is a Steering Angle Sensor?

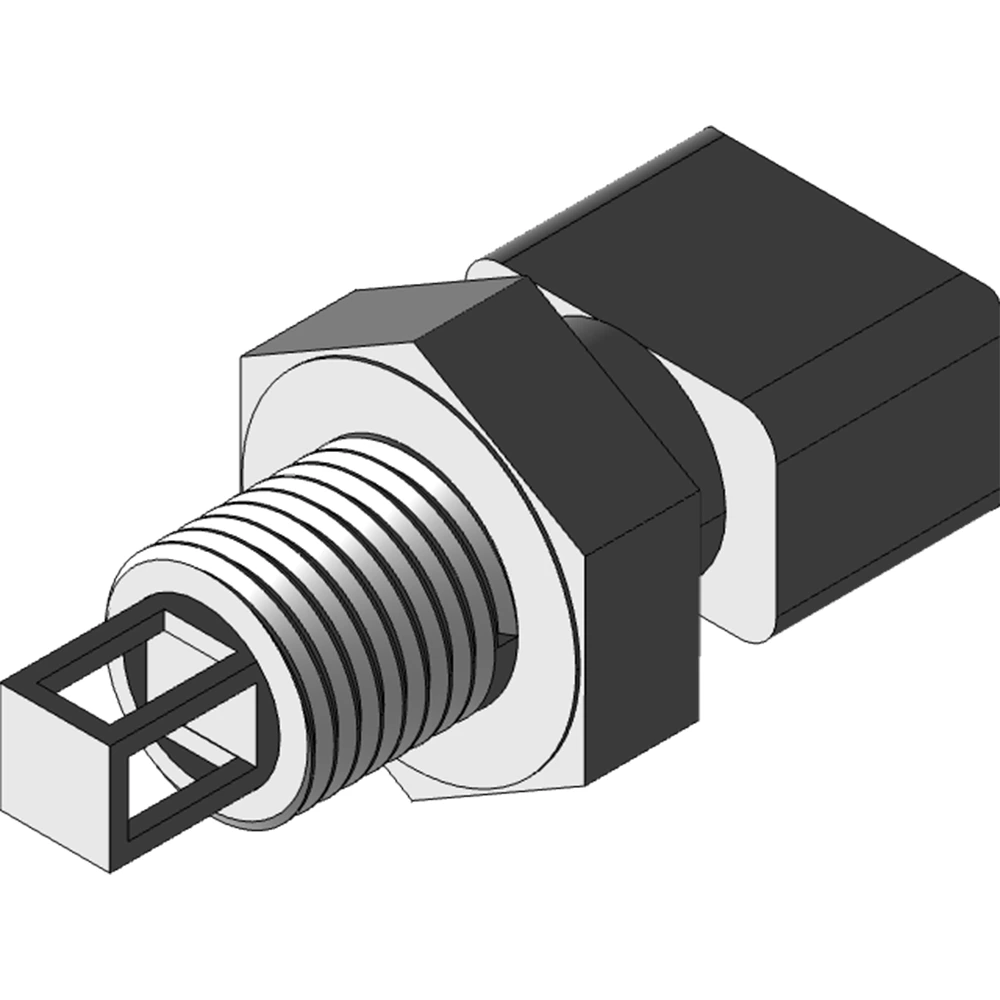

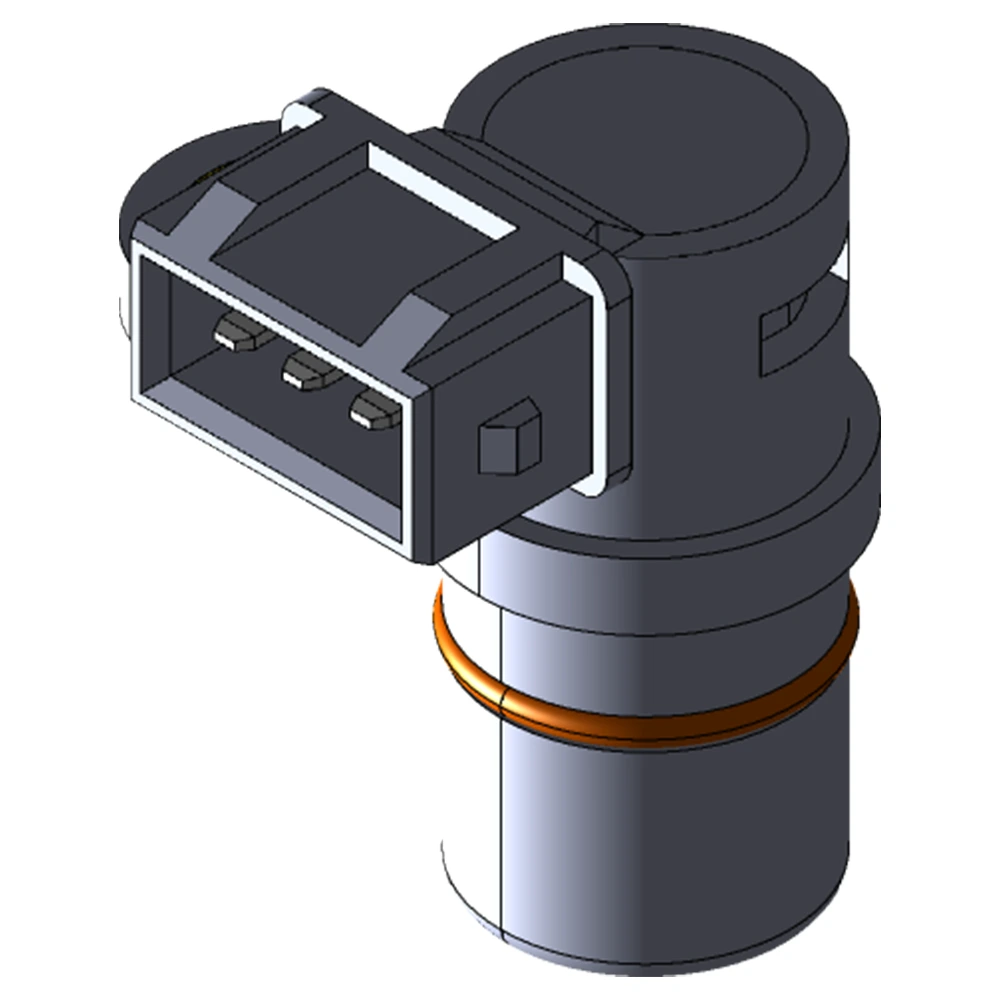

A steering angle sensor measures the rotation angle and direction of the steering wheel or steering shaft. Its primary function is to report real-time steering input to various vehicle control units. These sensors are typically mounted on the steering column, between the wheel and the electric power steering motor (EPS).

Depending on design, they may output:

- Absolute angle (full rotation position from 0° to ±720° or more)

- Relative angle (changes in direction or velocity)

- Zero-crossing and direction signals

Core Technologies Used in SAS

Steering angle sensors typically employ one of the following technologies:

- Optical Encoders

- Use a code disk and a light source to detect angular position

- High resolution and accuracy

- Sensitive to dust and temperature if not well sealed

- Hall-Effect Sensors

- Magnetic field-based measurement with fewer moving parts

- High reliability, good for harsh environments

- Common in mass-market automotive applications

- Resistive Potentiometers (Older Tech)

- Simple and low-cost

- Subject to wear and drift

- Rare in modern vehicles

Most OEM-qualified SAS products today combine dual-channel Hall-effect sensing with redundant processing to meet functional safety standards (e.g., ISO 26262 ASIL-B or higher).

Key Functions in Vehicle Dynamics

Steering angle data is crucial in multiple systems:

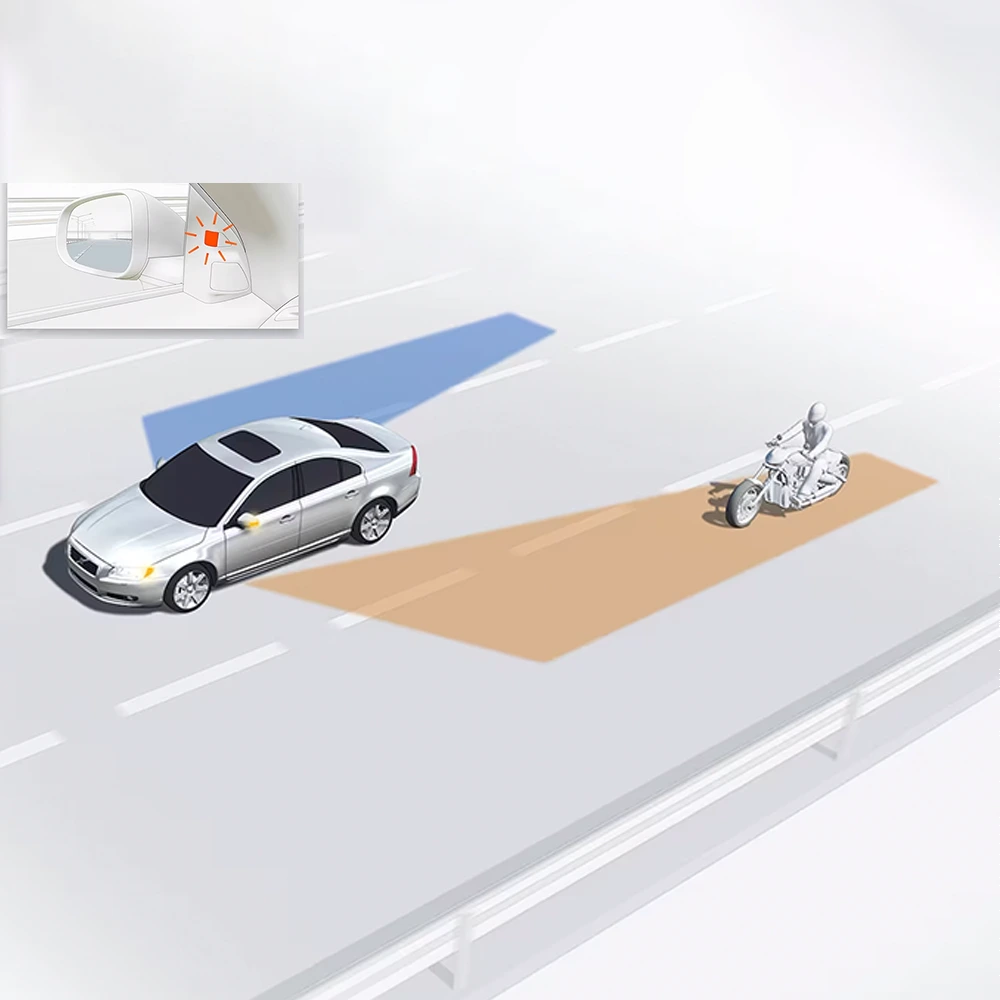

- Electronic Stability Program (ESP/ESC) Compares actual yaw movement with intended path. If vehicle is over- or understeering, the system applies corrective braking.

- Electric Power Steering (EPS) Adjusts steering assistance based on angle and steering speed.

- Advanced Driver Assistance Systems (ADAS) Supports lane keeping assist, adaptive cruise control, and automatic parking.

- Four-Wheel Steering & Torque Vectoring Uses steering input to coordinate rear wheel angle or torque distribution.

We don’t just think of the sensor in isolation — we see it as a signal source in a closed-loop control system, where timing, accuracy, and signal reliability are essential.

Signal Quality and System Synchronization

For real-time vehicle dynamics, latency and sampling rate are key. A high-performance steering angle sensor typically features:

- Sampling rate of ≥100 Hz

- Accuracy within ±1°

- Repeatability under harsh vibration and EMI conditions

It’s also common to include temperature compensation algorithms, diagnostic feedback, and self-calibration routines in the sensor firmware.

Steering Angle Sensor in the CAN Network

In many modern architectures, the SAS is integrated into the CAN bus or FlexRay network. It shares data with modules like:

- BCM (Body Control Module)

- EPS controller

- ABS/ESP unit

- ADAS ECU

For this reason, standardized data frames and robust error-checking (CRC, timeout monitoring) are a must.

The steering angle sensor is a quiet but critical part of any vehicle equipped with modern dynamic control systems. From the manufacturing engineer’s standpoint, its mechanical precision, signal integrity, and integration reliability are what determine whether advanced vehicle control features will perform smoothly and safely.

📚 Series Navigation

- ✅ Fundamentals of Automotive Steering Angle Sensors and Their Role in Vehicle Dynamics

- Design Architecture — Sensor Structure, Redundancy & Signal Interfaces

- Technical Specs that Matter — Resolution, Linearity, and Angular Range

- Environmental Testing & EMC Compliance in Real-World Applications

- Integration & Calibration on Vehicle Assembly Lines