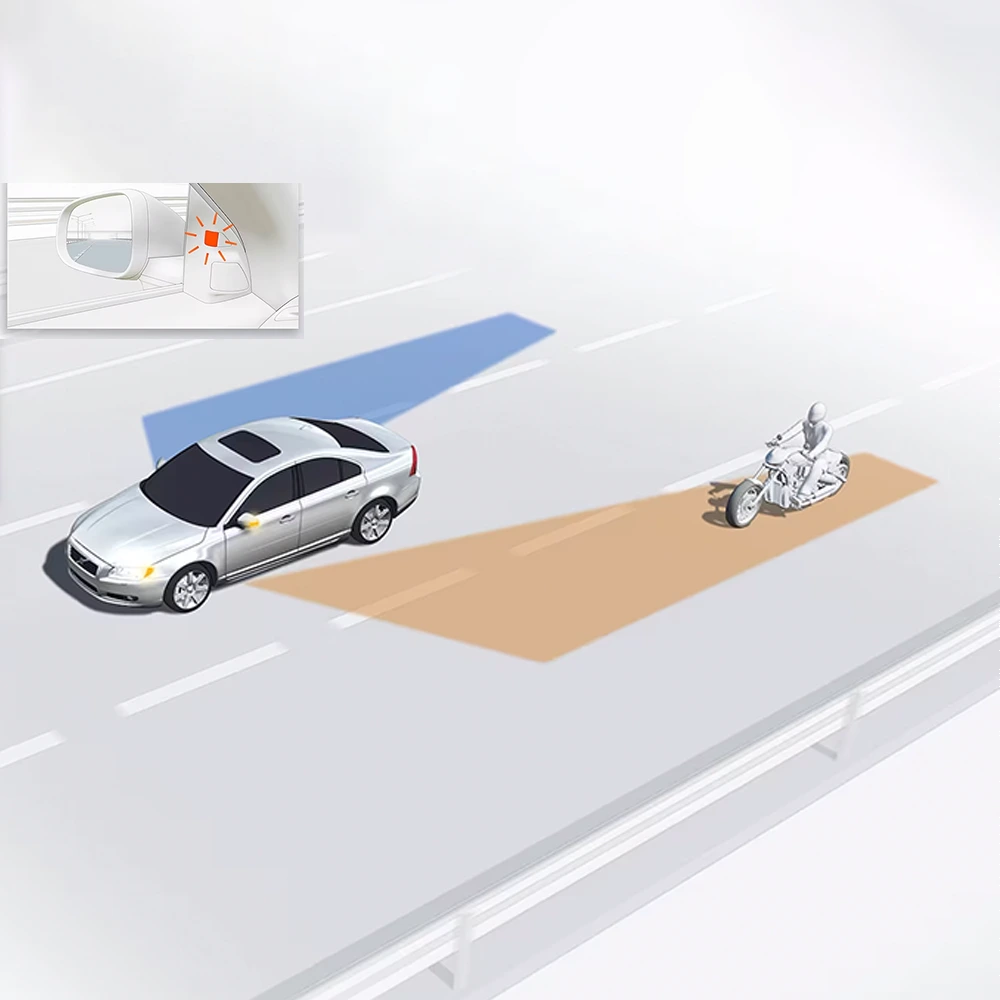

Modern vehicle emission systems form a complex, closed-loop network of sensors, control units, and after-treatment devices designed to monitor and minimize harmful exhaust pollutants. For sensor manufacturers, understanding each subsystem and its required sensor technologies is critical to delivering solutions that meet ever-tightening global regulations. This guide walks you through the emission system’s architecture, its principal hardware, the full roster of emission-control sensors, and tips for selecting the right sensor for each application.

1. Emission System Overview

- Purpose & Operation

Emission systems continuously sample intake and exhaust parameters, feeding data to the Engine Control Unit (ECU), which adjusts fuel injection timing, air-fuel ratio, and exhaust-gas recirculation (EGR) rates. After-treatment devices then chemically convert or physically trap pollutants before they exit the tailpipe. - Regulatory Drivers

Standards such as Euro 6 (EU), Tier 3 (US), and China 6 mandate progressively lower limits for CO, HC, NOₓ, and particulate matter (PM). Advanced, reliable sensors are foundational to achieving these targets without sacrificing drivability or fuel efficiency.

2. Core Emission Components

| Component | Function |

|---|---|

| Three-Way Catalytic Converter (TWC) | Converts CO, HC, and NOₓ into CO₂, H₂O, and N₂ via redox reactions. |

| Exhaust-Gas Recirculation (EGR) Valve | Routes a portion of exhaust back into the intake to lower combustion temperature and cut NOₓ. |

| Diesel Particulate Filter (DPF) | Physically captures soot; periodically regenerates by burning off accumulated PM. |

| Selective Catalytic Reduction (SCR) | Injects urea (AdBlue) to reduce NOₓ into N₂ and H₂O over a catalytic substrate. |

| Evaporative Emission Control (EVAP) | Traps fuel vapors in a charcoal canister and purges them into the intake to be burned. |

| Secondary Air Injection (SAI) | Injects fresh air during cold starts to accelerate catalyst light-off and oxidize HC/CO. |

3. Key Sensors in the Emission System

Below is the complete lineup of sensors that enable precise monitoring and control of the emission process:

- Oxygen (O₂) Sensor / Lambda Sensor

- Role: Measures residual oxygen in the exhaust upstream/downstream of the catalyst.

- Application: Guides air-fuel ratio adjustments for optimal catalyst performance.

- Nitrogen Oxides (NOₓ) Sensor

- Role: Detects NOₓ concentration before and after SCR.

- Application: Modulates urea dosing to maximize NOₓ reduction and prevent ammonia slip.

- Particulate Matter (PM) Sensor

- Role: Monitors soot concentration at DPF inlet and outlet.

- Application: Triggers DPF regeneration and verifies filter efficiency.

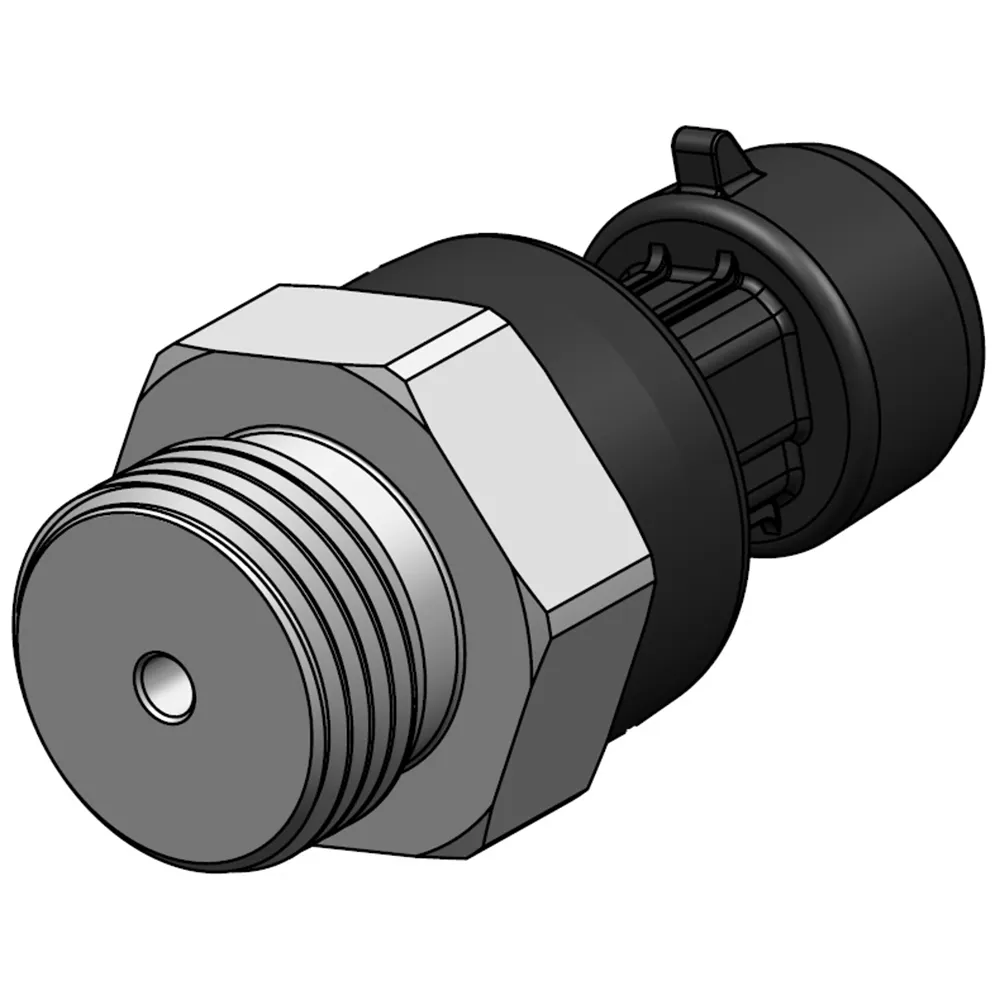

- Differential Pressure Sensor (DPF ΔP Sensor)

- Role: Measures pressure drop across the DPF.

- Application: Estimates soot loading and manages regeneration cycles.

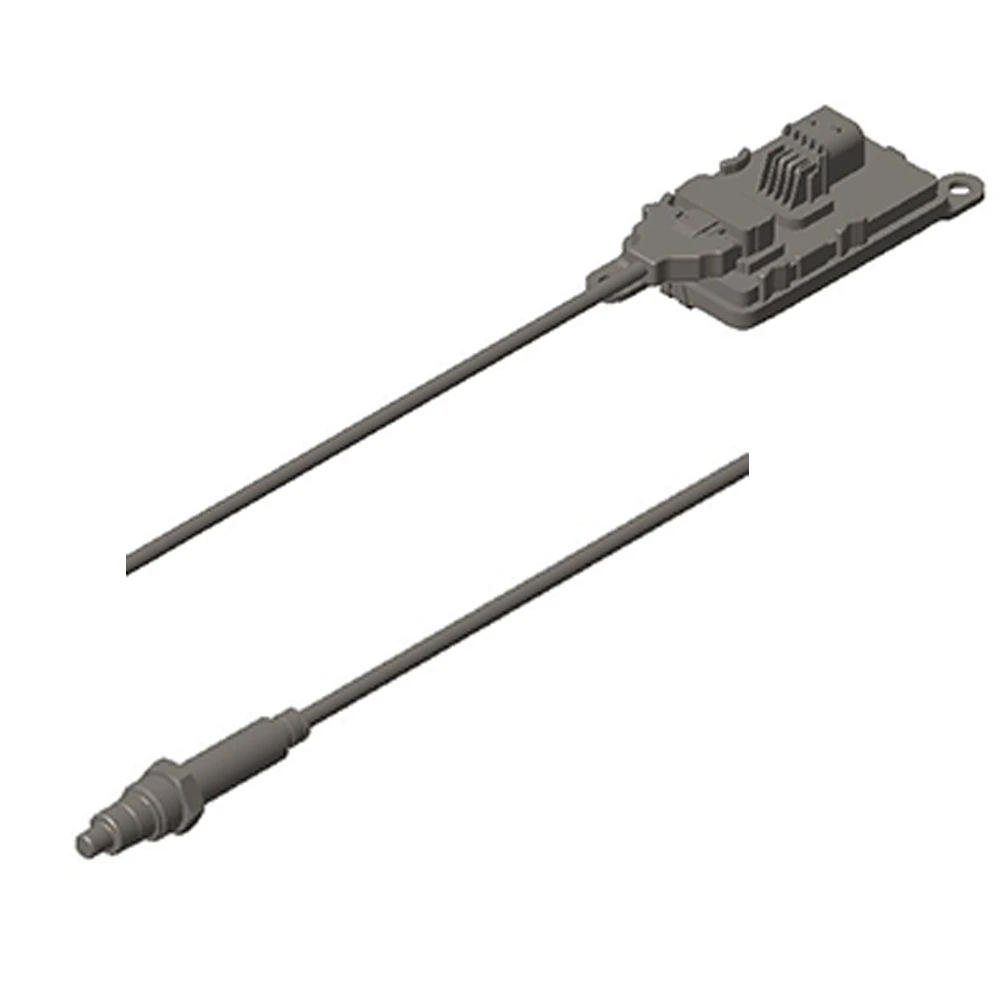

- Exhaust Gas Temperature (EGT) Sensor

- Role: Tracks exhaust temperature at strategic points (EGR cooler, DPF, SCR).

- Application: Protects components from overheating and ensures effective regeneration.

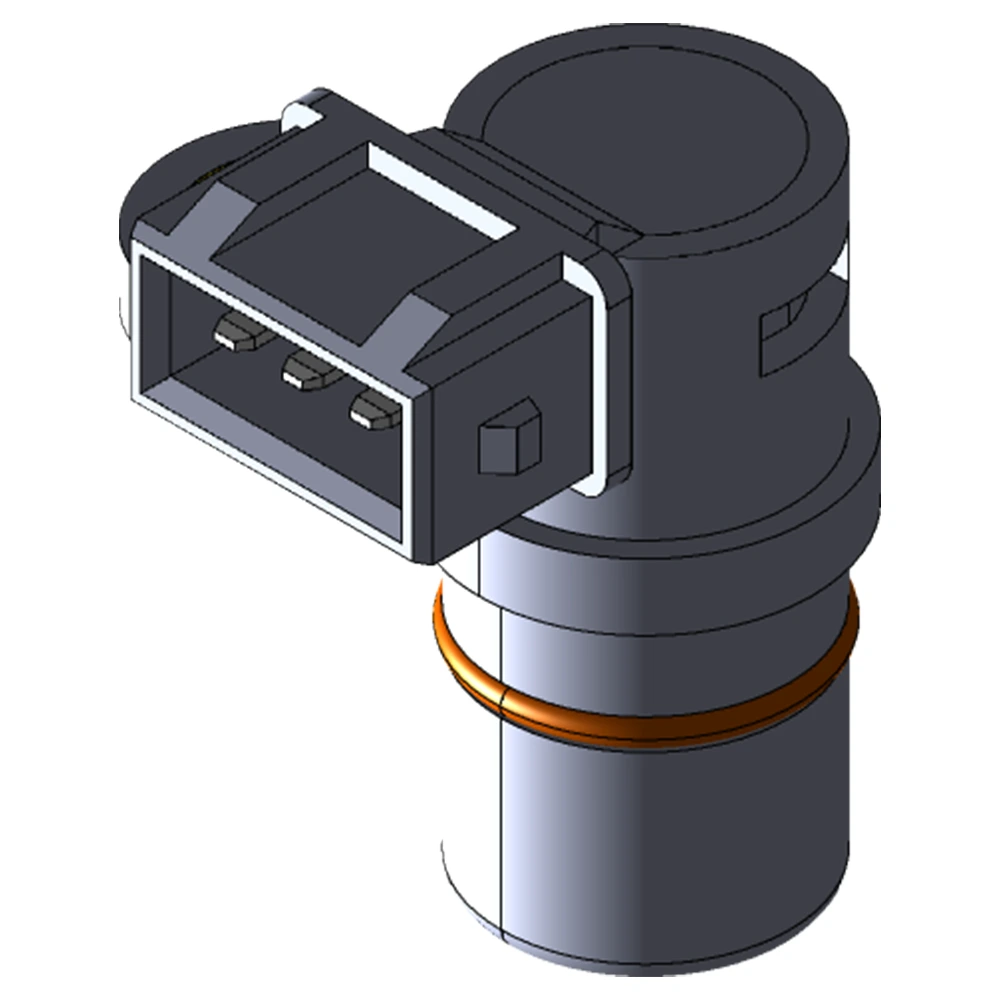

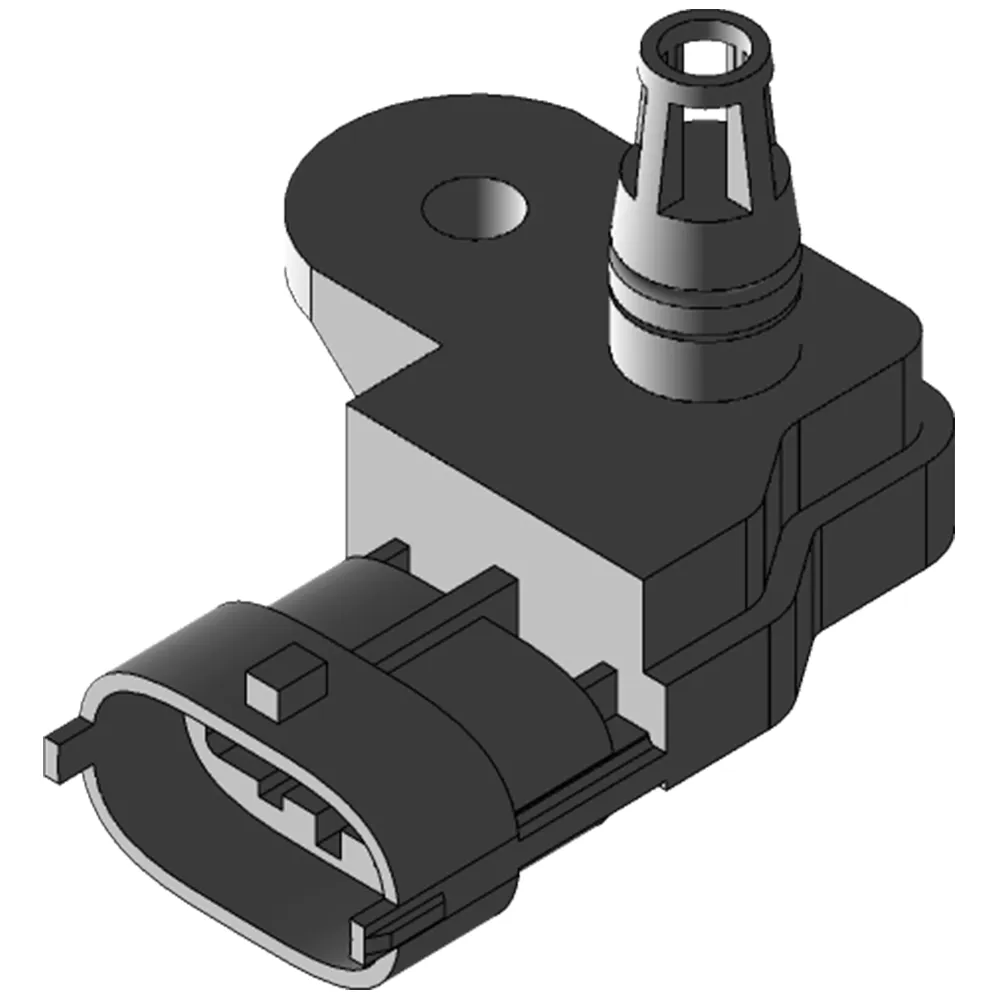

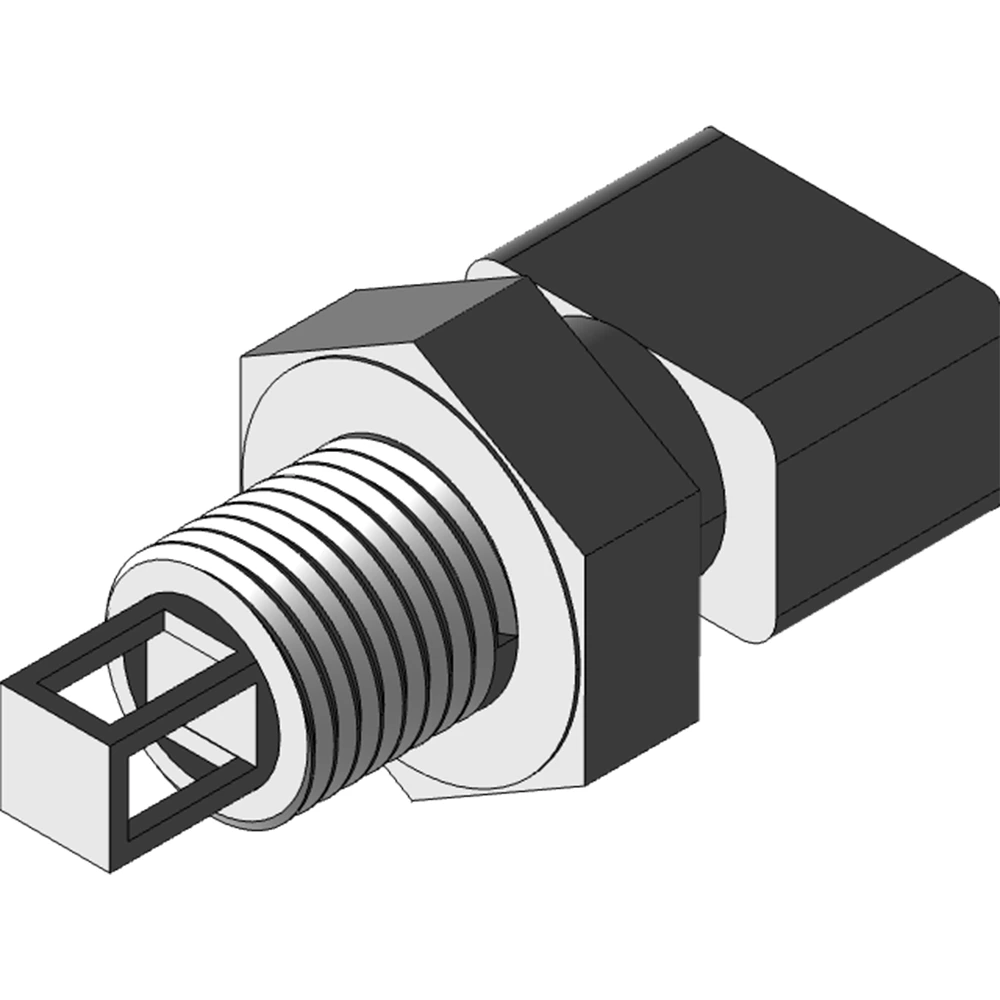

- Manifold Absolute Pressure (MAP) Sensor

- Role: Measures intake manifold pressure.

- Application: Assists in calculating engine load and air-mass flow for ECU control.

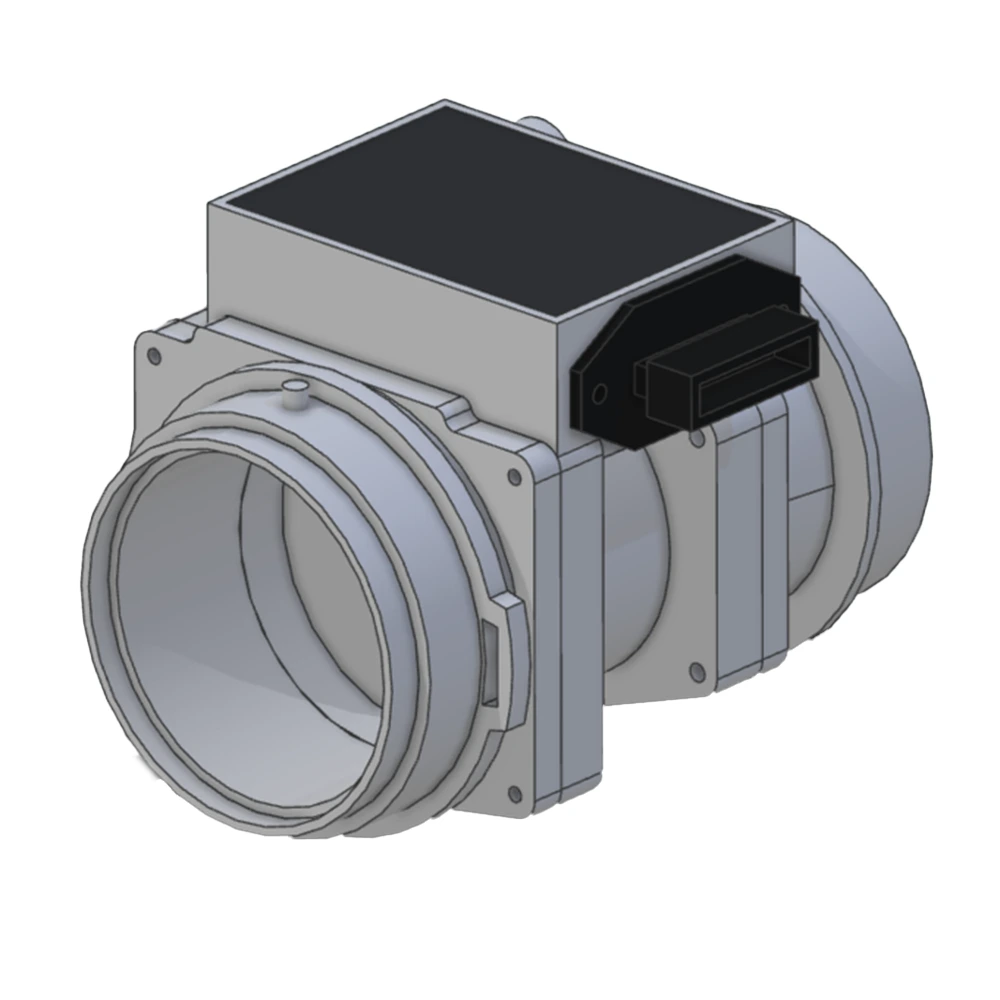

- Mass Air Flow (MAF) Sensor

- Role: Senses the mass of air entering the engine.

- Application: Crucial for accurate fuel metering and combustion control.

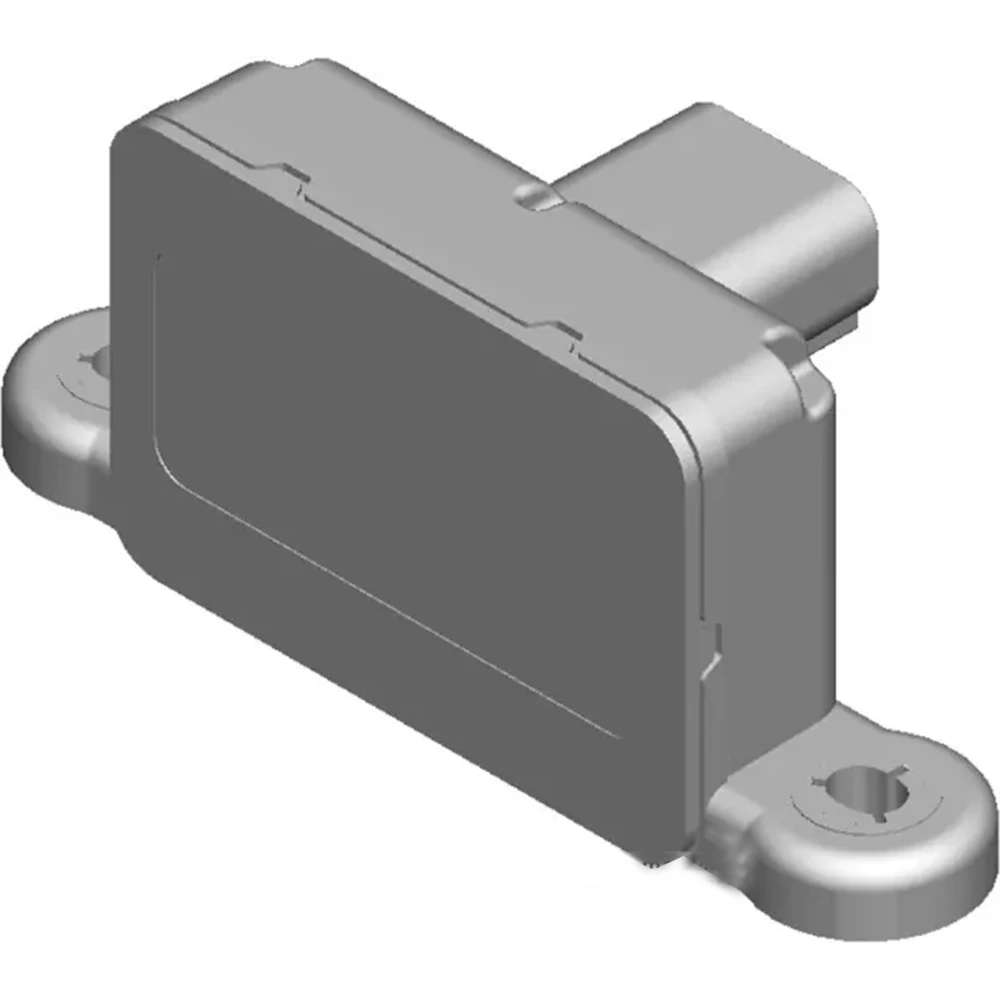

- Intake Air Temperature (IAT) Sensor

- Role: Records the temperature of incoming air.

- Application: Helps ECU adjust fuel injection and EGR rates based on air density.

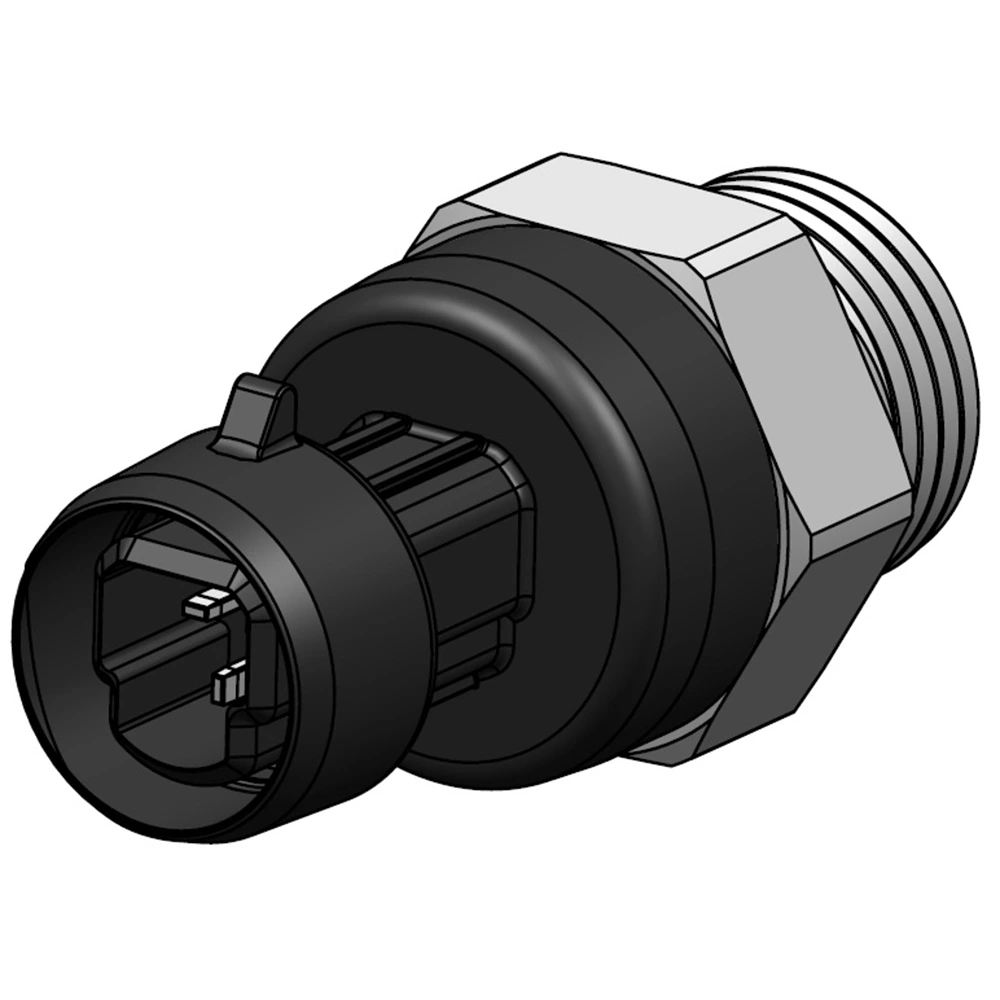

- Fuel Tank Pressure Sensor

- Role: Monitors pressure changes in the fuel tank for the EVAP system.

- Application: Detects leaks and ensures proper vapor capture and purge cycles.

- EVAP Canister/Vent Pressure Sensor

- Role: Measures pressure in the charcoal canister and vent lines.

- Application: Controls purge valve timing and verifies EVAP integrity.

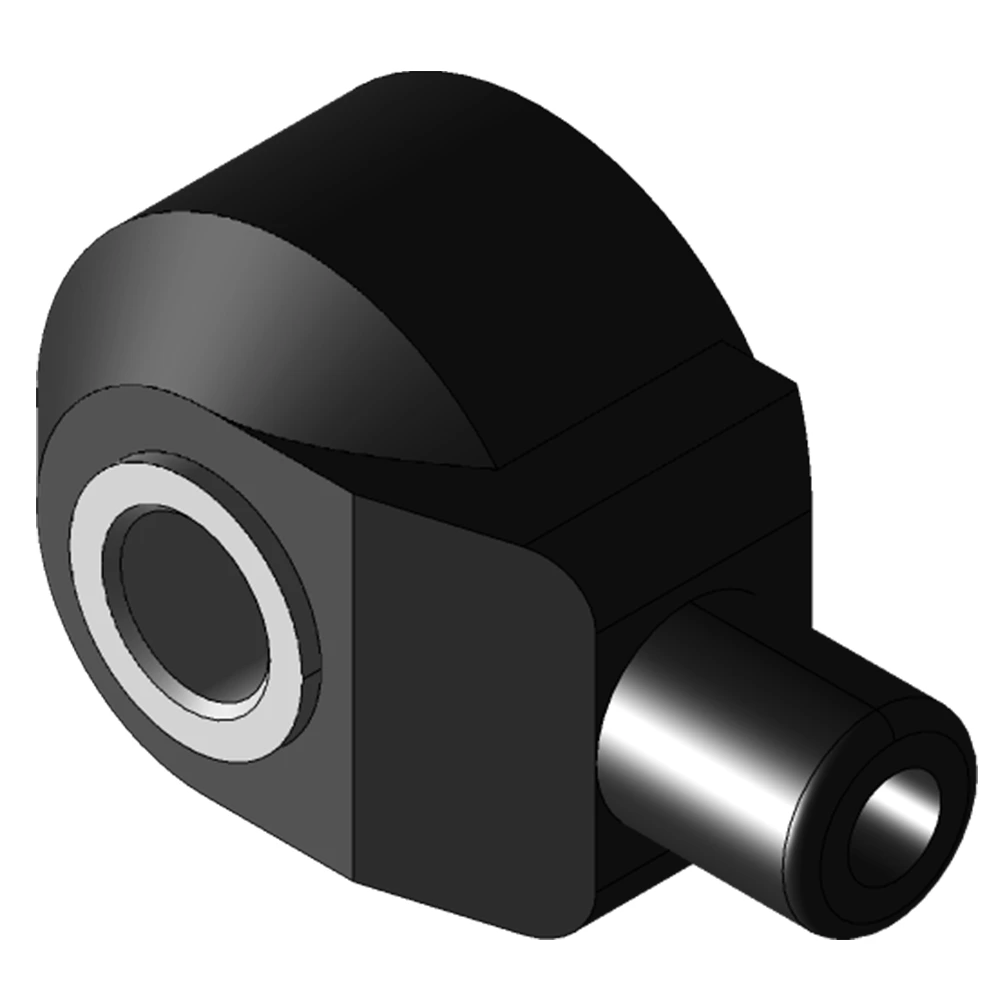

- EGR Valve Position Sensor

- Role: Reports actual EGR valve opening.

- Application: Ensures commanded EGR flow matches real-world flow rates.

- AdBlue Level/Quality Sensor

- Role: Senses urea solution level and concentration.

- Application: Prevents SCR system underdosing or overdosing.

- Ammonia Slip (NH₃) Sensor

- Role: Detects unreacted ammonia downstream of SCR.

- Application: Triggers corrective action to avoid ammonia emissions.

- Crankcase Pressure (PCV) Sensor

- Role: Measures pressure in the crankcase ventilation system.

- Application: Prevents excessive blow-by and HC emissions.

- Hydrocarbon (HC) Sensor

- Role: Detects unburned hydrocarbons in exhaust or intake.

- Application: Fine-tunes cold-start enrichment and catalyst light-off.

Conclusion

The modern emission system is a finely tuned orchestration of sensors, control logic, and chemical reactors, all working together to meet stringent environmental standards. Moocar, as a sensor specialist, a thorough grasp of each sensor’s role—and of the harsh conditions in which they operate—will empower you to deliver robust, high-performance products that keep tomorrow’s vehicles clean, compliant, and reliable.