In automotive electronics, technical specifications are only half the story. The other half? Surviving the harsh realities of the road. I’ve seen even well-designed sensors fail under long-term exposure to heat, vibration, or electromagnetic interference. In this article, we’ll cover how steering angle sensors (SAS) are validated through rigorous environmental and EMC (electromagnetic compatibility) testing, ensuring they perform reliably across the full vehicle lifecycle.

Why Environmental Testing Matters

Steering angle sensors are often mounted inside steering columns or close to the firewall — locations that experience:

- Temperature extremes (–40°C to +125°C or more)

- Moisture ingress

- Constant vibration

- Electromagnetic fields from adjacent electronics

These factors can affect:

- Signal accuracy

- Output stability

- Mechanical wear

- Internal PCB and solder reliability

“The field doesn’t care how well a sensor works in the lab — only how it performs at 60°C under the dash of a vibrating, rain-soaked truck.”

Key Environmental Tests for SAS

1. Temperature & Thermal Shock Testing

- High-temp soak (e.g. +125°C for 1,000 hours)

- Low-temp storage (e.g. –40°C for 72 hours)

- Thermal cycling: –40°C ↔ +125°C, 100+ cycles

- Purpose: Test material expansion, solder integrity, and zero-point drift

2. Humidity and Salt Spray

- Damp heat cycles: 95% RH at 85°C

- Salt spray (ISO 9227): Tests corrosion resistance of housing and connectors

- Purpose: Simulate coastal or high-moisture environments

3. Vibration & Mechanical Shock

- Sine/random vibration: up to 10–2000 Hz

- Mechanical shock: 50 g/11 ms pulses in 3 axes

- Purpose: Ensure internal magnet and PCB mounting won’t shift

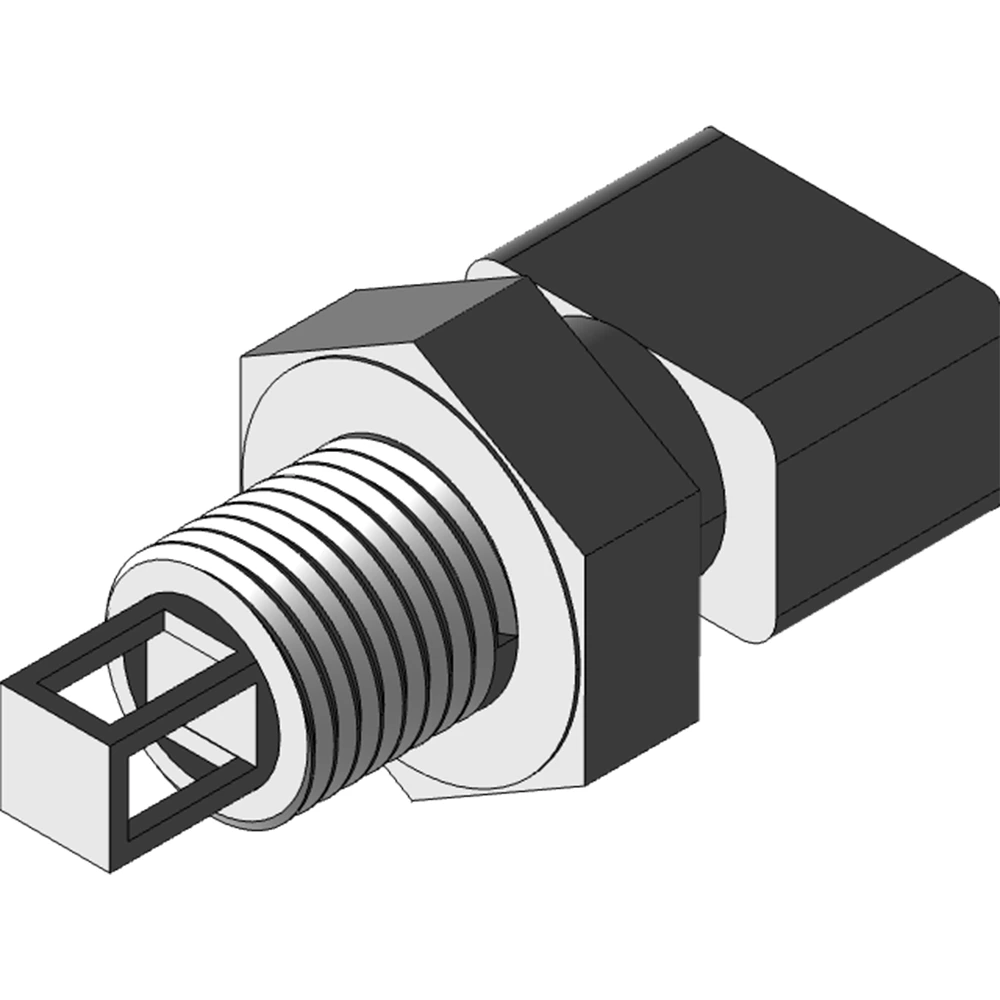

4. Ingress Protection (IP Rating)

- Target: IP67 or IP6K9K for sealed sensors

- Tested for water immersion and high-pressure spray

- Important for underhood or exposed installations

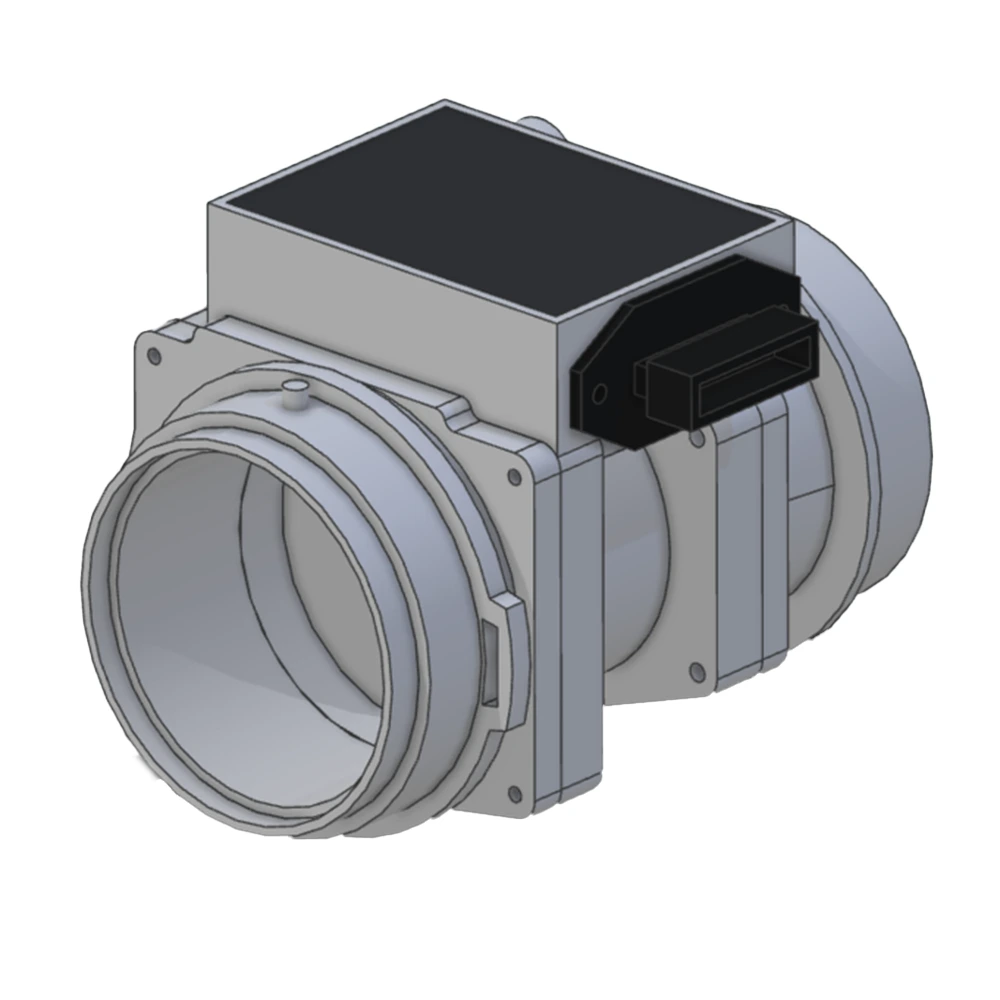

EMC Testing for Steering Angle Sensors

Electromagnetic compatibility (EMC) is a major challenge for steering sensors, which operate near:

- High-current EPS motors

- CAN/LIN buses

- High-voltage hybrid inverters

Common Standards:

- ISO 11452 series (immunity to radiated/conducted RF)

- CISPR 25 (conducted/radiated emissions)

- ISO 7637-2 (transient immunity on power lines)

Typical Tests:

- Bulk current injection (BCI)

- Radiated RF immunity (up to 200 V/m)

- ESD immunity: ±8 kV contact, ±15 kV air

- Load dump pulses: up to +87V for 400 ms

“Without proper EMI filtering, even a mobile phone near the steering column could disrupt angle signals — a risk we can’t afford.”

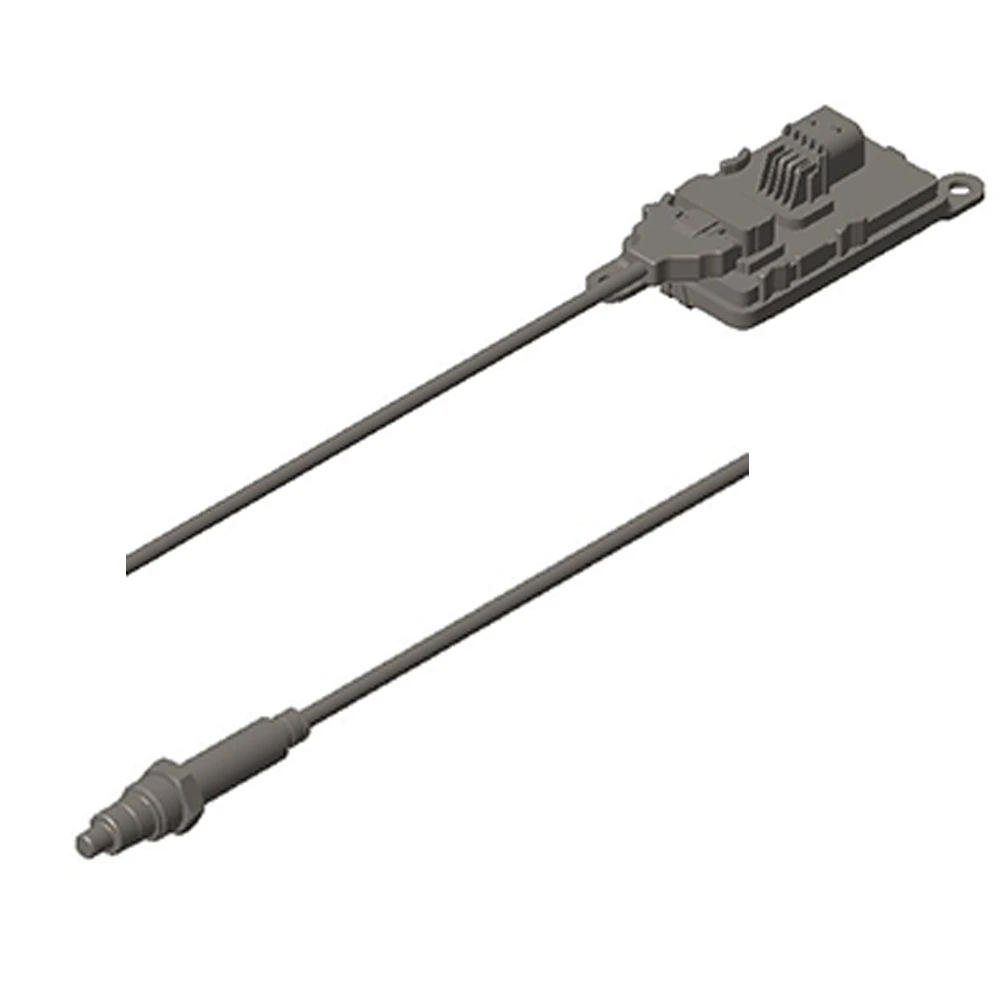

Design Considerations for Compliance

To pass the above tests, engineers integrate:

- TVS diodes on signal and power lines

- Shielded connectors and twisted-pair wiring

- Optimized ground plane layout on PCBs

- Internal watchdogs and fault detection logic

- Sealed housing and potting for IP protection

In premium designs, shielded enclosures of magnetically compensated layouts may be used to resist external field interference.

Rugged by Design, Proven by Test

A steering angle sensor isn’t truly “automotive-grade” unless it survives the full gauntlet of environmental and EMC tests. It must remain accurate and safe under heat, cold, water, vibration, and electromagnetic fields — all while meeting tight tolerances.

From a manufacturing engineer’s view: the difference between a good sensor and a great one is how it holds up five years later — not just how it works when new.

📚 Serie Navigatie

- Basisprincipes van stuurhoeksensoren voor auto's en hun rol in voertuigdynamiek

- Ontwerparchitectuur - Sensorstructuur, redundantie en signaalinterfaces

- Technische specificaties die ertoe doen: resolutie, lineariteit en hoekbereik

- ✅ Milieutesten en EMC-naleving in toepassingen in de praktijk

- Integratie en kalibratie op voertuigassemblagelijnen