As emission regulations tighten, NOₓ sensor technology must evolve to provide ever-greater precision, robustness, and lower cost. This article explores three leading NOₓ sensing methods—electrochemical, solid-state, and emerging CMOS MEMS—highlighting design trade‑offs, advanced materials, and performance benchmarks that are shaping next‑generation exhaust monitoring.

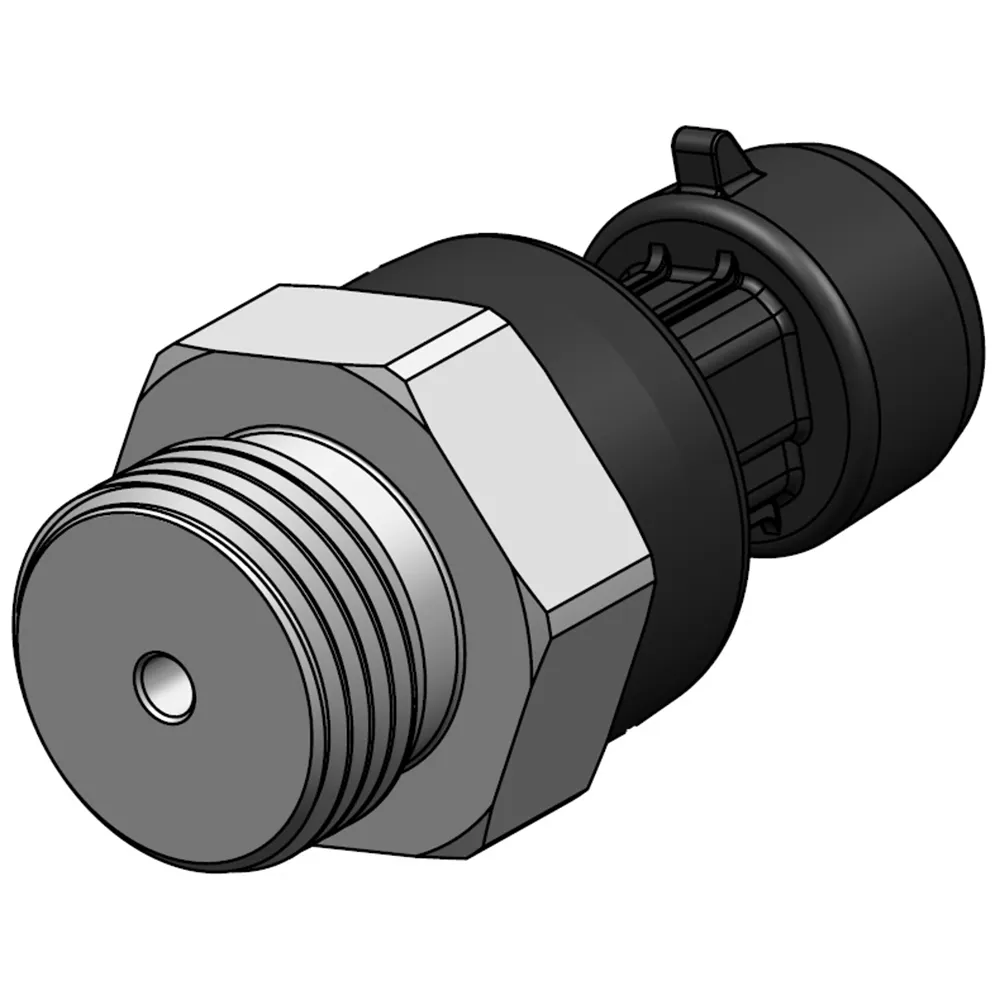

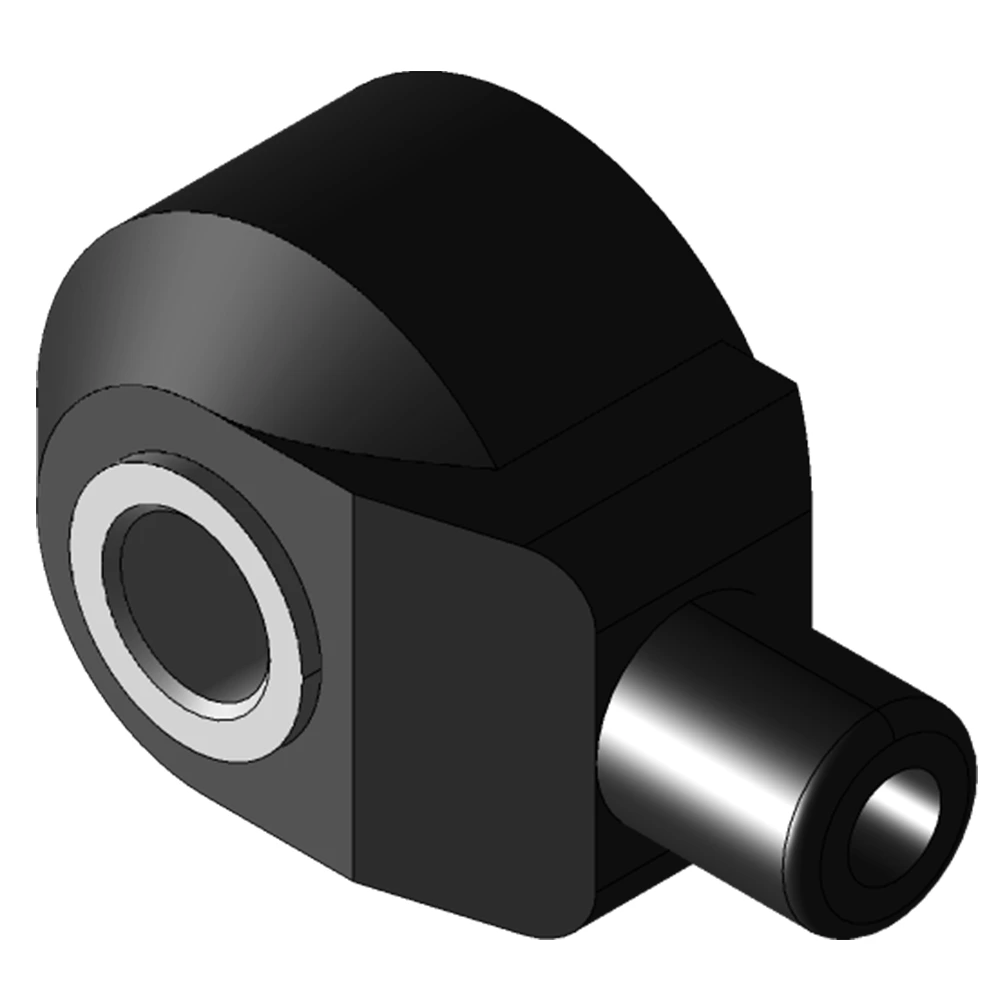

1. Electrochemical NOₓ Sensors: Proven Performance

Electrochemical sensors remain the industry standard for many SCR applications due to their linear response and high sensitivity.

- Operating Principle: An electrode pair immersed in a potassium‑based electrolyte generates current when NO or NO₂ undergoes redox reactions. Current magnitude correlates with gas concentration.

- Key Advantages: Excellent low‑end sensitivity (<5 ppm), stable output over wide temperature ranges (−40 to 800 °C), and straightforward signal conditioning.

- Material Innovations: Recent use of ionic liquids and novel electrode catalysts (e.g., ruthenium‑doped platinum) improves selectivity against interfering gases like CO and NH₃.

- Design Considerations: Requires periodic calibration to compensate electrolyte degradation; active heating elements maintain optimal electrolyte conductivity in cold-start conditions.

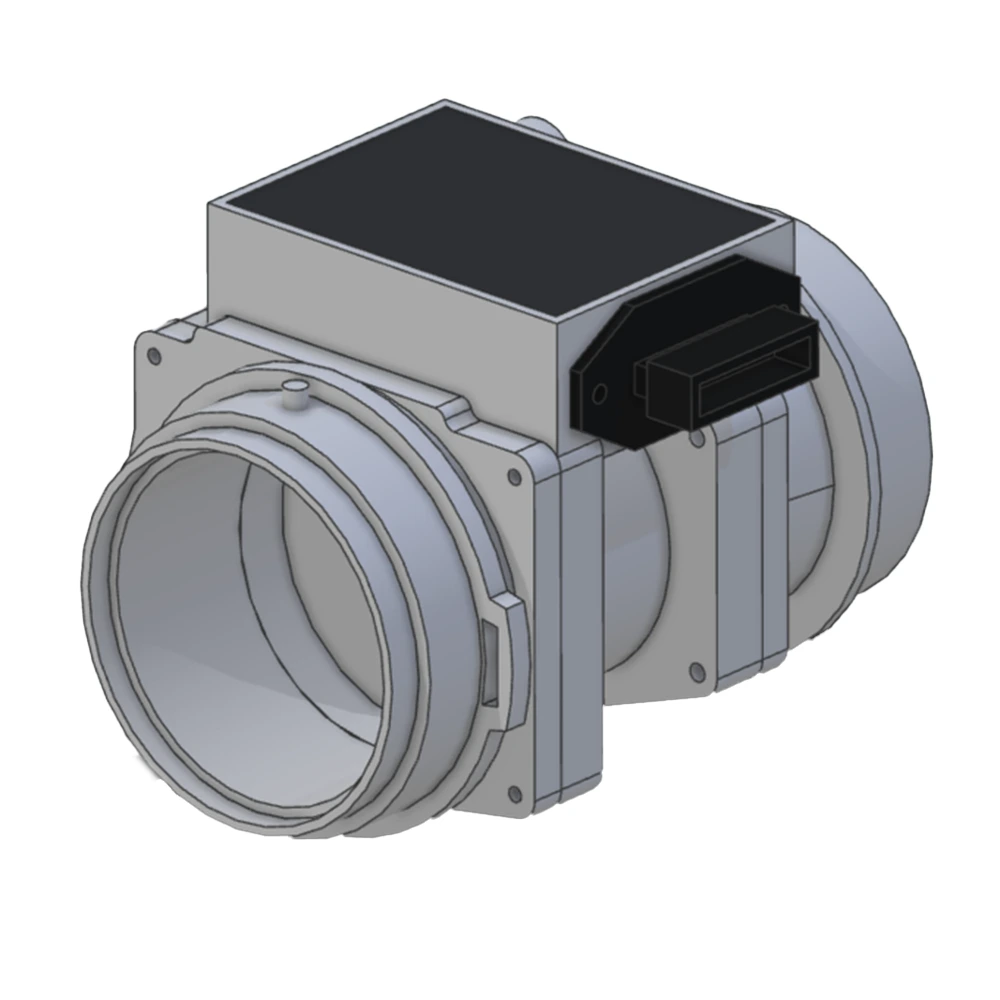

2. Solid-State NOₓ Sensors: Durability Meets Cost Efficiency

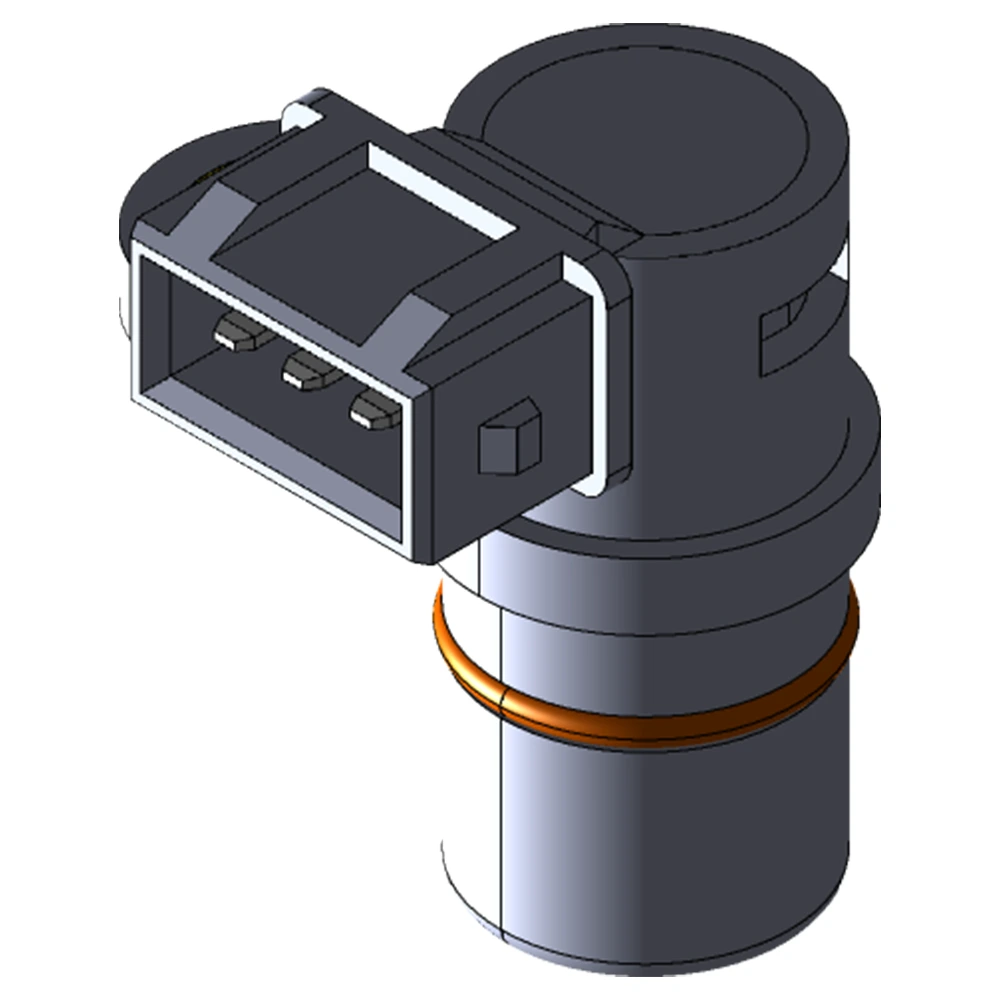

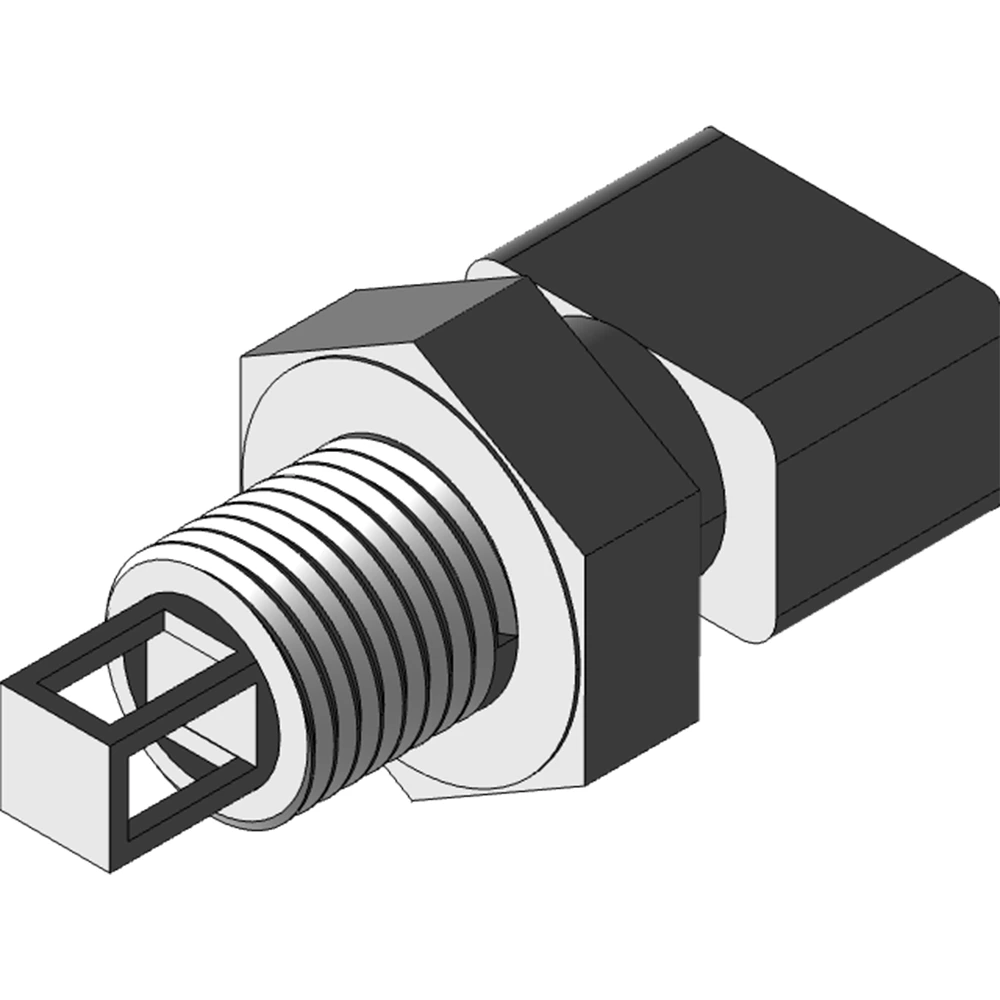

Solid-state sensors leverage metal-oxide semiconductors (MOS) to detect NOₓ through resistance changes.

- Operating Principle: A sensing film of doped cerium oxide or tungsten oxide adsorbs NOₓ, altering its electrical resistance. This change is measured across interdigitated electrodes.

- Advantages: Rugged ceramic packaging tolerates >900 °C, no liquid electrolyte means simplified maintenance, and batch microfabrication lowers unit cost.

- Challenges: Cross-sensitivity to humidity and other gases; modern designs use layered filters—e.g., catalytic topcoats—to enhance selectivity and suppress drift.

- Application Insight: Ideal for heavy-duty diesel engines with high exhaust temperatures, where low maintenance and cost are paramount.

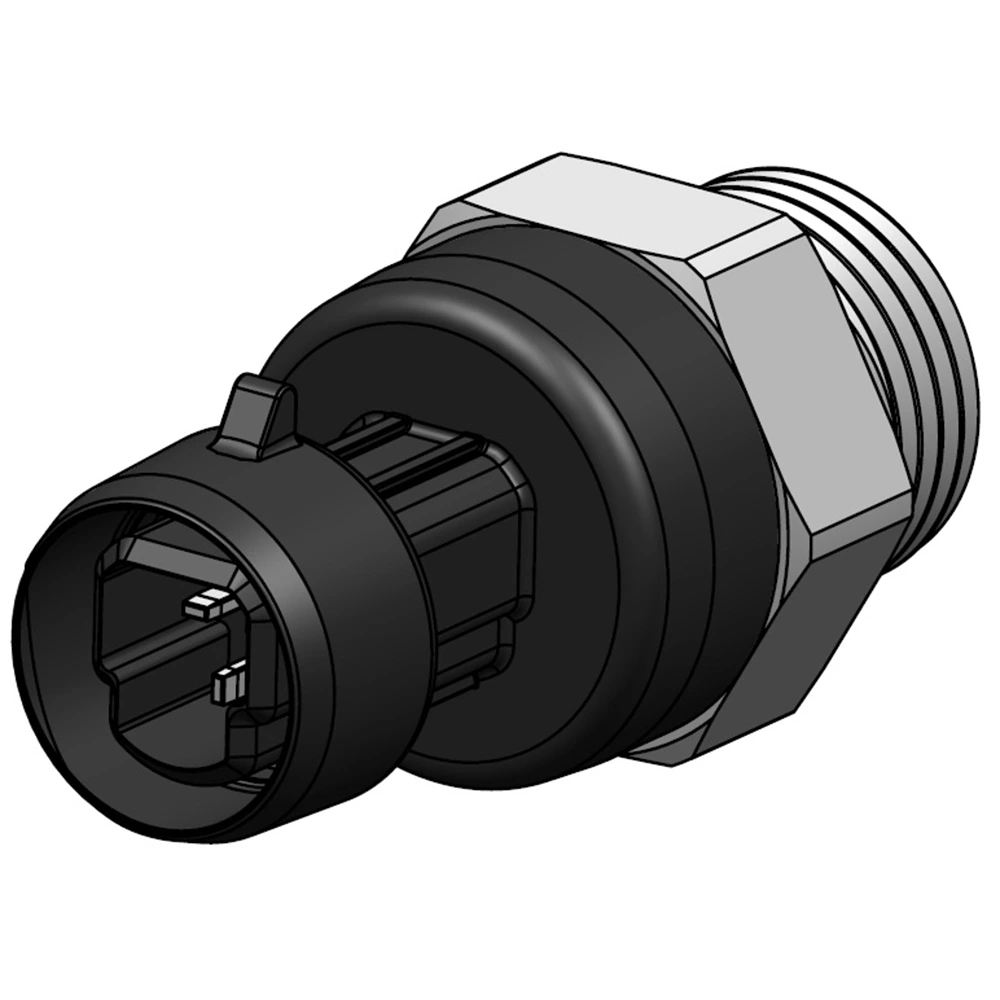

3. CMOS MEMS NOₓ Sensors: The Next Frontier

Microelectromechanical systems (MEMS) integrated with CMOS circuits are unlocking new form factors and intelligence.

- Operating Principle: Microfabricated cantilevers or micro-hotplates coated with NOₓ-selective nanomaterials (e.g., graphene‑oxide composites) transduce gas adsorption into measurable electrical or mechanical signals.

- Benefits: Ultra-low power consumption (<50 mW), on-chip signal processing, and potential integration with wireless modules for IoT deployment.

- Research Highlights: Novel surface functionalization techniques yield sub-ppm detection limits and reduced response times (<10 ms). Early field trials show promising stability over 1,000+ hours at 700 °C.

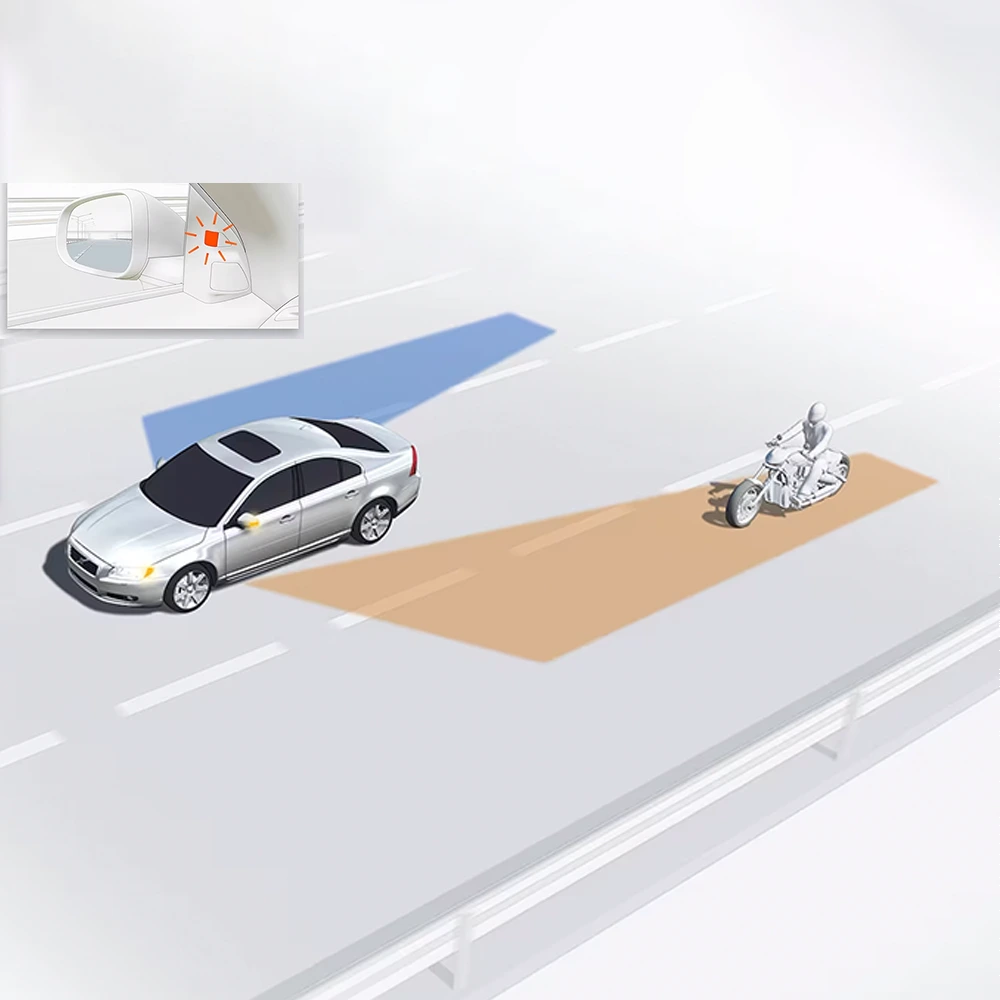

- Integration Opportunities: MEMS sensors can be co‑located with O₂ sensors on a single die, reducing harness complexity and enabling multi‑parameter emission monitoring.

4. High-Temperature Materials and Coatings

Reliable NOₓ sensing demands materials that resist sintering, poisoning, and thermal shock.

- Sensor Substrates: Alumina ceramics and silicon carbide (SiC) offer structural integrity at >1,000 °C.

- Protective Coatings: Porous platinum or perovskite overcoats filter particulates and moisture while allowing NOₓ diffusion.

- Catalytic Layers: Incorporating palladium or rhodium nanoclusters enhances NO to NO₂ conversion, improving sensor response consistency.

5. Performance Metrics: Sensitivity, Selectivity, and Response Time

Key benchmarks for comparing NOₓ sensors:

| Metric | Electrochemical | Solid-State | MEMS/COS |

|---|---|---|---|

| Sensitivity | 1–1,000 ppm | 5–5,000 ppm | 0.1–500 ppm |

| Selectivity | High (via membrane) | Moderate (filter) | High (functionalization) |

| Response Time | 100–500 ms | 500–1,000 ms | <10 ms |

| Operating Range | −40–800 °C | 200–900 °C | 0–750 °C |

Sensor selection should align these metrics with target engine profiles and regulatory requirements.

Advances in electrochemical catalysts, MOS materials, and MEMS fabrication are driving NOₓ sensors toward new levels of performance and integration.