Sintomas de falha e possíveis causas

Fumaça preta

- A válvula rotativa/válvula de gatilho de controle de pressão de reforço não fecha

- Sistema de filtro de ar lubrificante

- Compressor ou refrigerador de ar sujo

- Juntas rachadas/ausentes ou soltas na entrada de ar do motor

- Resistência excessiva ao fluxo no sistema de exaustão / vazamento a montante da turbina

- Danos por corpo estranho no compressor ou turbina

- Sistema de combustível/injeção com defeito ou ajustado incorretamente

- Fornecimento insuficiente de óleo no carregador de turfa

- Tubo de sucção e pressão distorcido ou com vazamento

- Carcaça/válvula da turbina danificada

- Danos aos rolamentos do turbo

- Guia de válvula, anéis de pistão, camisas de motor ou cilindro desgastadas/batidas aumentadas

Fumaça azul

- Coque e depósitos no centro do turbocompressor

- Ventilação do cárter bloqueada e distorcida

- Sistema de filtro de ar lubrificante

- Compressor ou refrigerador de ar sujo

- Resistência excessiva ao fluxo no sistema de exaustão / vazamento a montante da turbina

- Tubos de abastecimento e drenagem de óleo obstruídos, vazando ou distorcidos

- Vedação do anel do pistão com defeito

- Danos aos rolamentos do turbo

- Guia de válvula, anéis de pistão, camisas de motor ou cilindro desgastadas/batidas aumentadas

Turbocompressor gera ruído acústico

- Compressor ou refrigerador de ar sujo

- Juntas rachadas/ausentes ou soltas na entrada de ar do motor

- Resistência excessiva ao fluxo no sistema de exaustão / vazamento a montante da turbina

- Vazamento de gás de escape entre o tubo de escape da turbina e o tubo de escape

- Danos por corpo estranho no compressor ou turbina

- Fornecimento insuficiente de óleo no carregador de turfa

- Tubo de sucção e pressão distorcido ou com vazamento

- Carcaça/válvula da turbina danificada

- Danos aos rolamentos do turbo

A pressão de reforço está muito alta

- A válvula rotativa/válvula de gatilho de controle de pressão de reforço não abre

- Sistema de combustível/injeção com defeito ou ajustado incorretamente

- Colete de tubo. Válvula rotativa/válvula de assento com defeito

Compressor/roda da turbina com defeito

- Danos por corpo estranho no compressor ou turbina

- Fornecimento insuficiente de óleo no carregador de turfa

- Carcaça/válvula da turbina danificada

- Danos aos rolamentos do turbo

Vazamento de óleo na turbina

- Coque e depósitos no centro do turbocompressor

- Ventilação do cárter bloqueada e distorcida

- Tubos de abastecimento e drenagem de óleo obstruídos, vazando ou distorcidos

- Vedação do anel do pistão com defeito

- Danos aos rolamentos do turbo

- Guia de válvula, anéis de pistão, camisas de motor ou cilindro desgastadas/batidas aumentadas

Alto consumo de óleo

- Coque e depósitos no centro do turbocompressor

- Ventilação do cárter bloqueada e distorcida

- Sistema de filtro de ar lubrificante

- Compressor ou refrigerador de ar sujo

- Resistência excessiva ao fluxo no sistema de exaustão / vazamento a montante da turbina

- Tubos de abastecimento e drenagem de óleo obstruídos, vazando ou distorcidos

- Vedação do anel do pistão com defeito

- Danos aos rolamentos do turbo

- Guia de válvula, anéis de pistão, camisas de motor ou cilindro desgastadas/batidas aumentadas

Potência insuficiente/pressão de reforço muito baixa

- A válvula rotativa/válvula de gatilho de controle de pressão de reforço não fecha

- Sistema de filtro de ar lubrificante

- Compressor ou refrigerador de ar sujo

- Juntas rachadas/ausentes ou soltas na entrada de ar do motor

- Resistência excessiva ao fluxo no sistema de exaustão / vazamento a montante da turbina

- Danos por corpo estranho no compressor ou turbina

- Sistema de combustível/injeção com defeito ou ajustado incorretamente

- Fornecimento insuficiente de óleo no carregador de turfa

- Colete de tubo. Válvula rotativa/válvula de assento com defeito

- Tubo de sucção e pressão distorcido ou com vazamento

- Carcaça/válvula da turbina danificada

- Danos aos rolamentos do turbo

- Guia de válvula, anéis de pistão, camisas de motor ou cilindro desgastadas/batidas aumentadas

Vazamento de óleo no compressor

- Coque e depósitos no centro do turbocompressor

- Ventilação do cárter bloqueada e distorcida

- Sistema de filtro de ar lubrificante

- Compressor ou refrigerador de ar sujo

- Resistência excessiva ao fluxo no sistema de exaustão / vazamento a montante da turbina

- Tubos de abastecimento e drenagem de óleo obstruídos, vazando ou distorcidos

- Vedação do anel do pistão com defeito

- Danos aos rolamentos do turbo

- Guia de válvula, anéis de pistão, camisas de motor ou cilindro desgastadas/batidas aumentadas

Obtenha suporte total

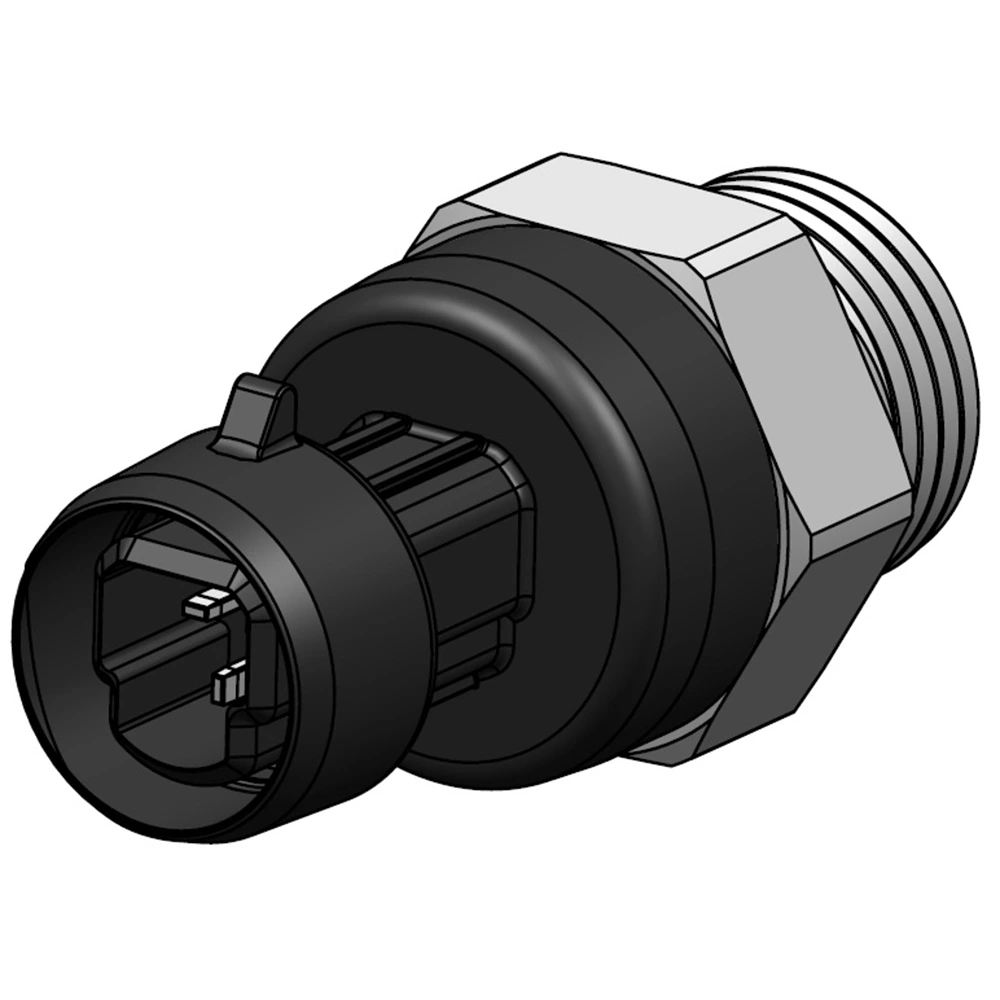

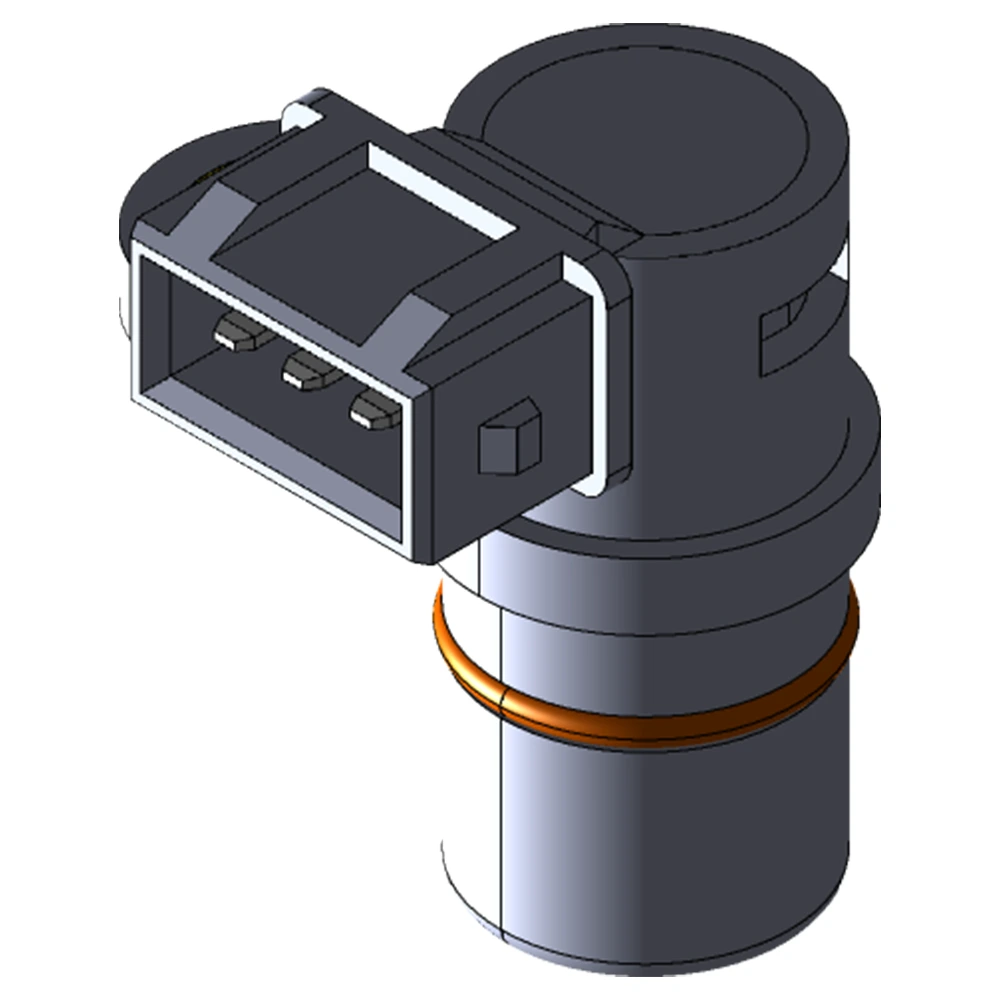

MOOCAR — como exportador líder, desenvolvemos continuamente soluções inovadoras de sensoriamento e atuação para ajudar a otimizar o controle de emissões, a economia de combustível e a dirigibilidade. Além dos componentes mencionados acima, oferecemos suporte completo de dados e informações de mercado.

[formulário ninja id=2]