Nitrogen oxides (collectively termed NOₓ, primarily NO and NO₂) are byproducts of high-temperature combustion in internal combustion engines. These gases contribute significantly to smog formation, acid rain, and respiratory health issues. To combat these hazards, regulators worldwide enforce strict NOₓ limits, making precise monitoring a cornerstone of any modern emission-control strategy.

1. How NOₓ Sensors Work: Core Principles

At their heart, NOₓ sensors measure exhaust gas chemistry using electrochemical or solid-state principles:

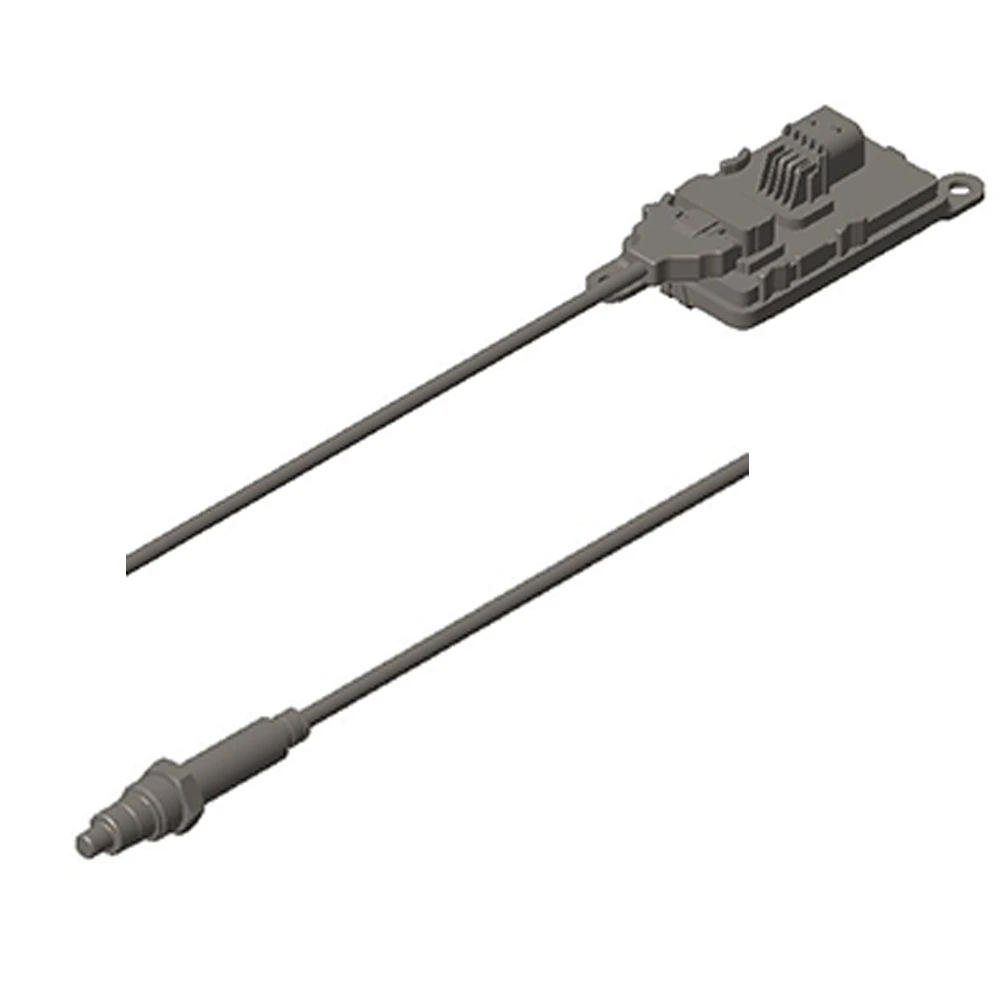

- Electrochemical Sensors: These devices contain two electrodes immersed in an electrolyte. When NOₓ molecules diffuse through a selective membrane, they undergo redox reactions at the electrodes, producing a current proportional to gas concentration. Their high sensitivity and linear response make them a popular choice for SCR systems.

- Solid-State Sensors: Leveraging metal-oxide semiconductor materials, these sensors detect NOₓ by monitoring resistance changes as molecules adsorb and react on the sensor surface. Advances in material science (e.g., doped ceria or mixed metal oxides) have enhanced their selectivity and temperature resilience.

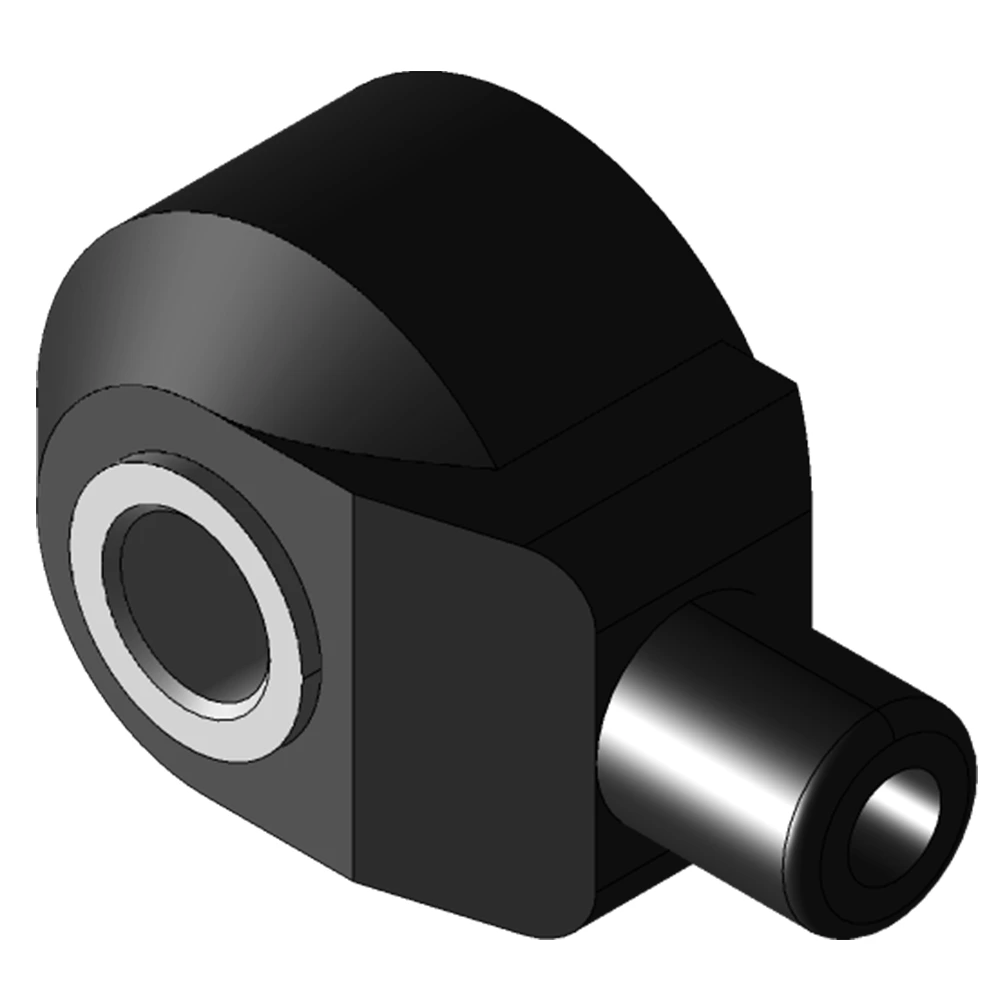

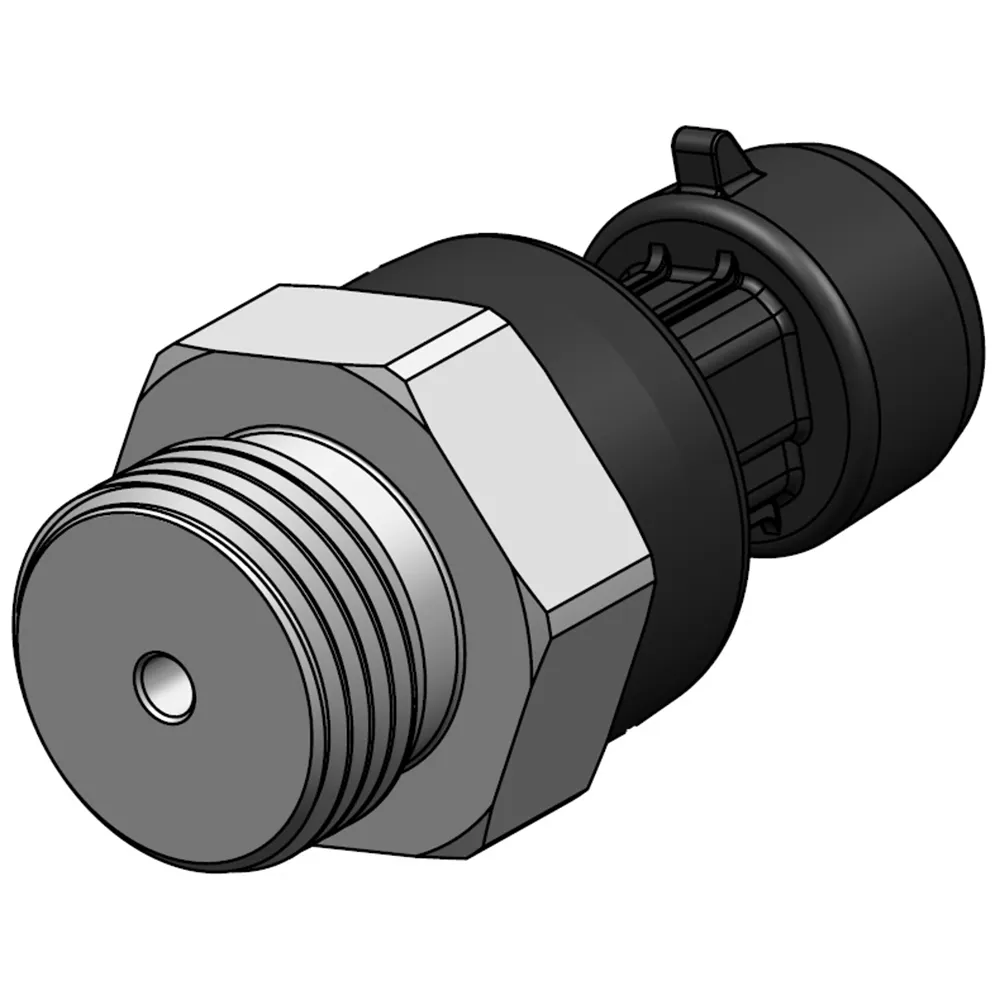

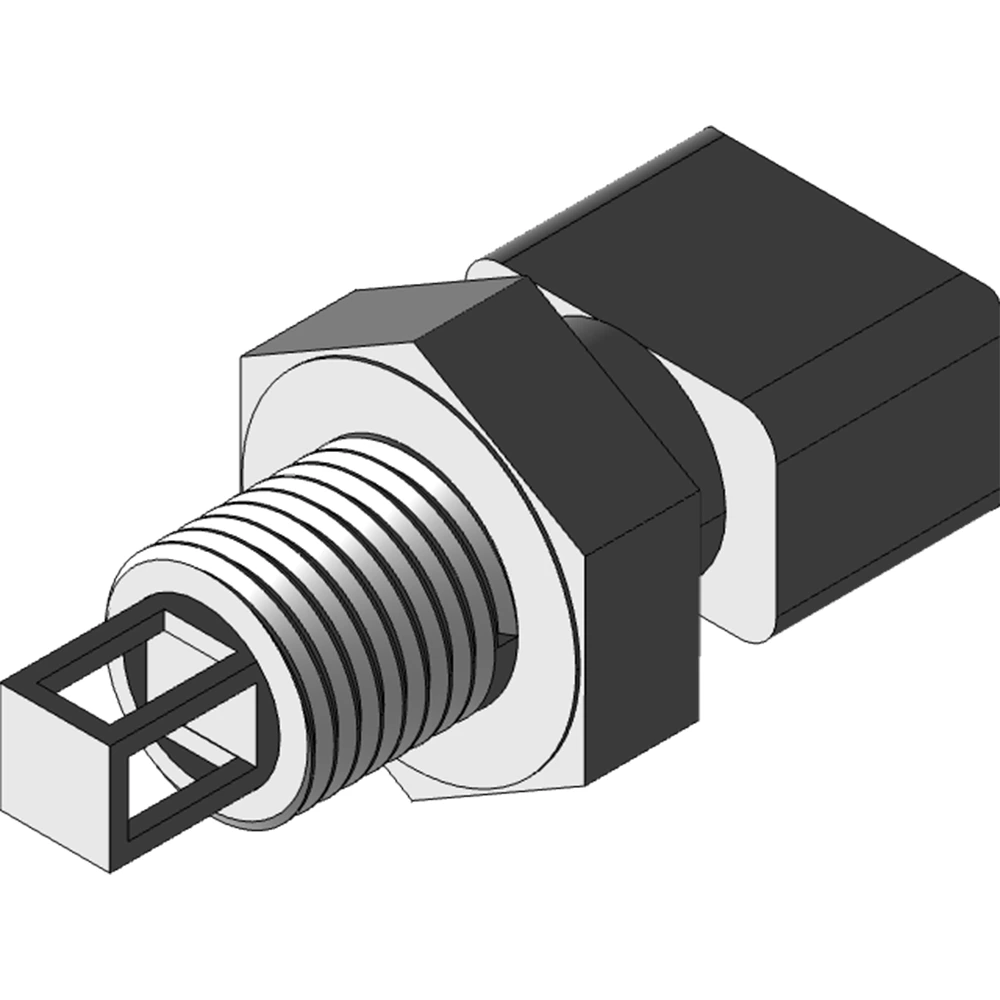

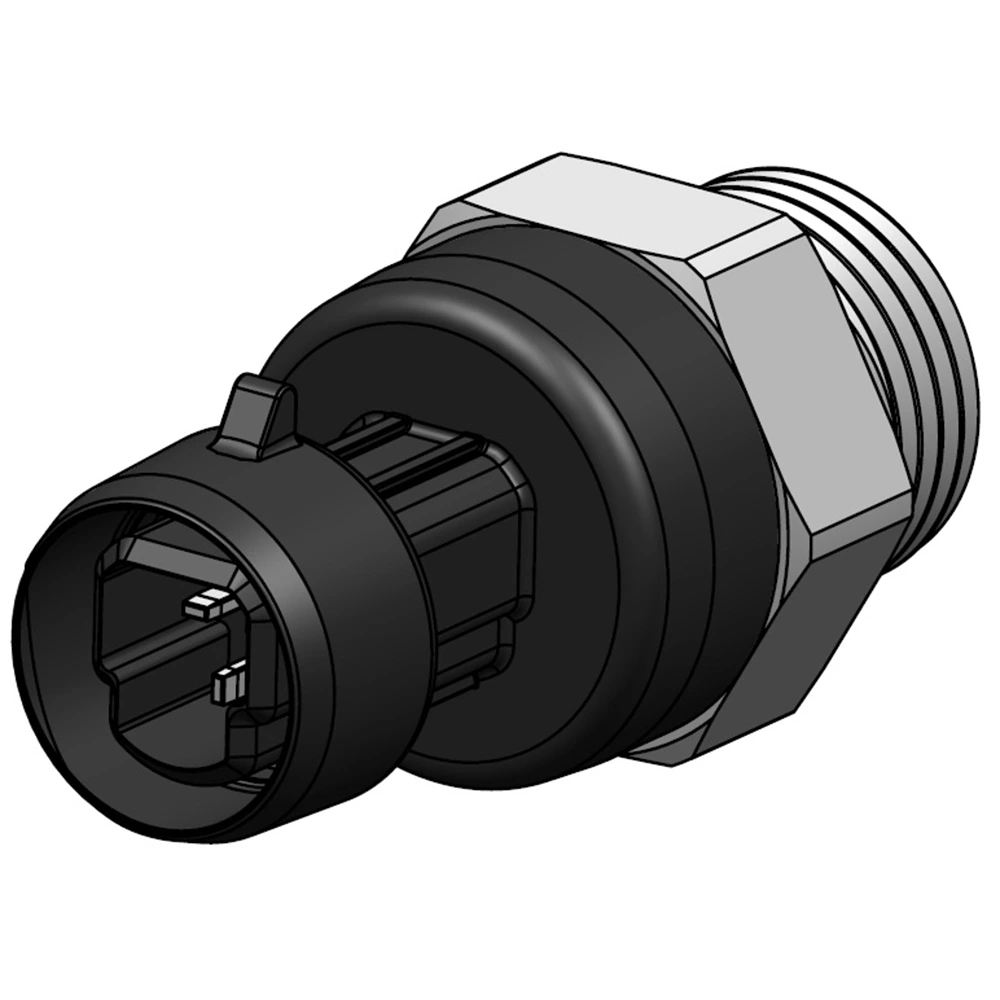

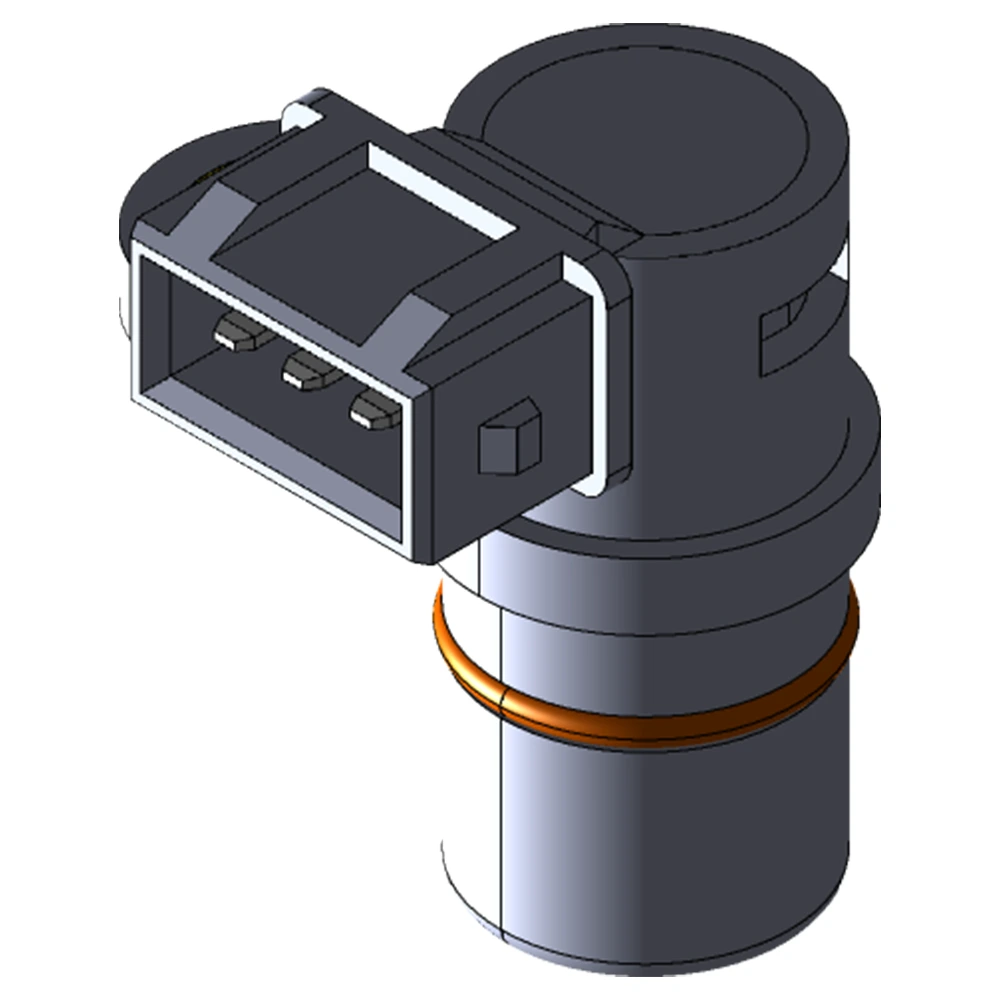

Regardless of type, NOₓ sensors must endure exhaust temperatures often exceeding 600 °C, necessitating robust housings, thermal insulation, and active heating elements to maintain optimal operating conditions.

2. Role of NOₓ Sensors in SCR After-Treatment

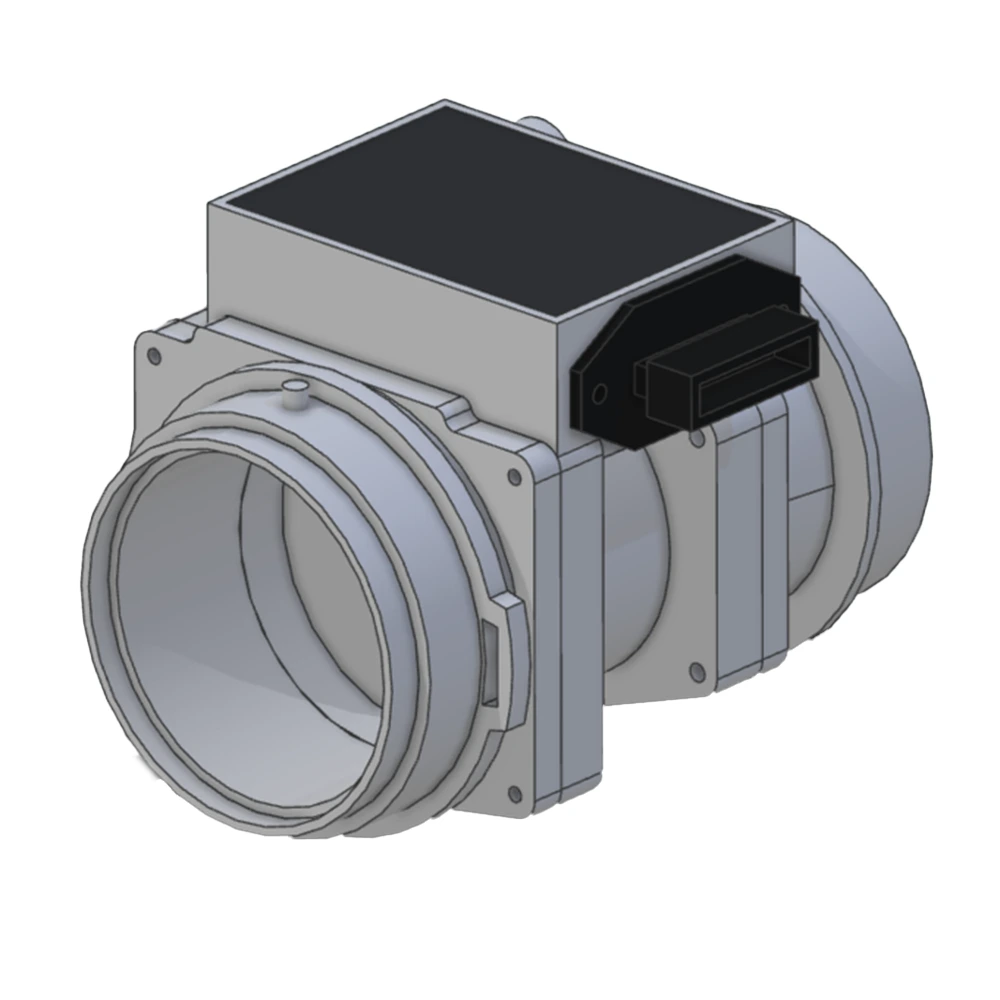

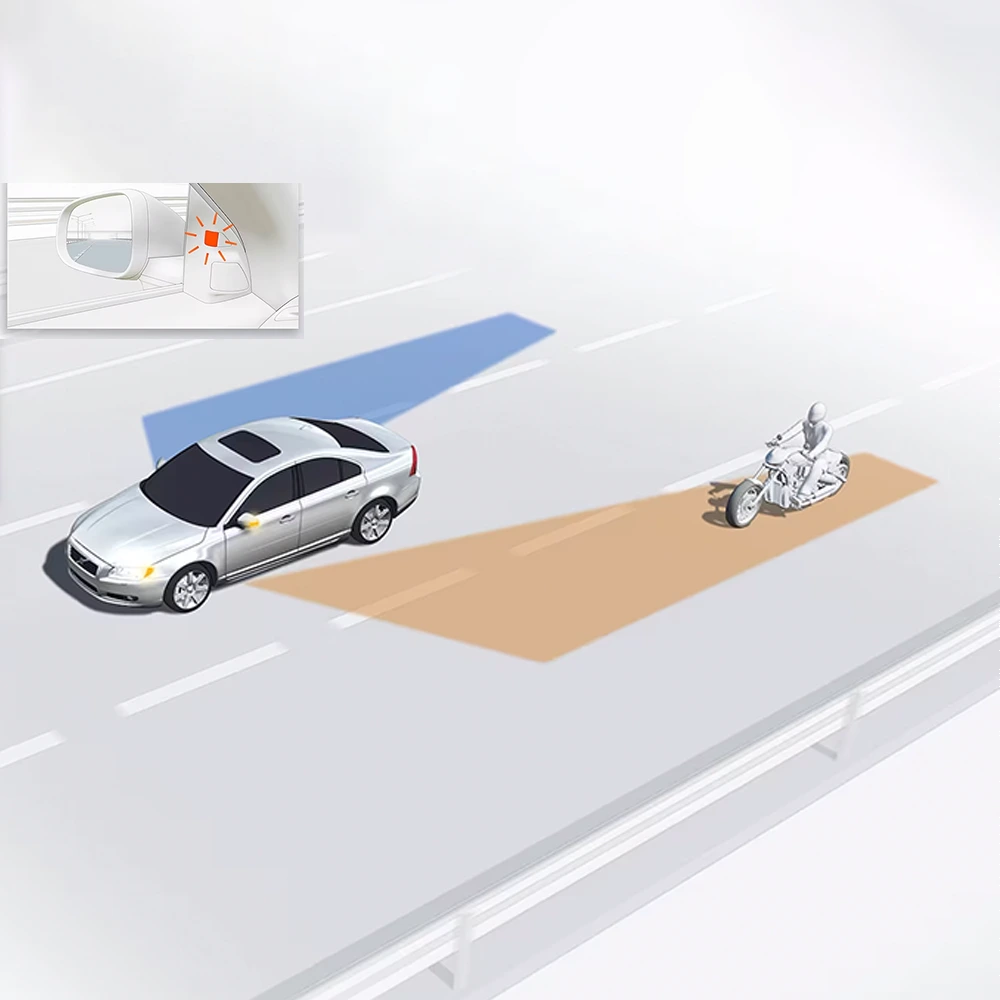

Selective Catalytic Reduction (SCR) systems rely on precise NOₓ measurements to optimize urea (AdBlue) dosing:

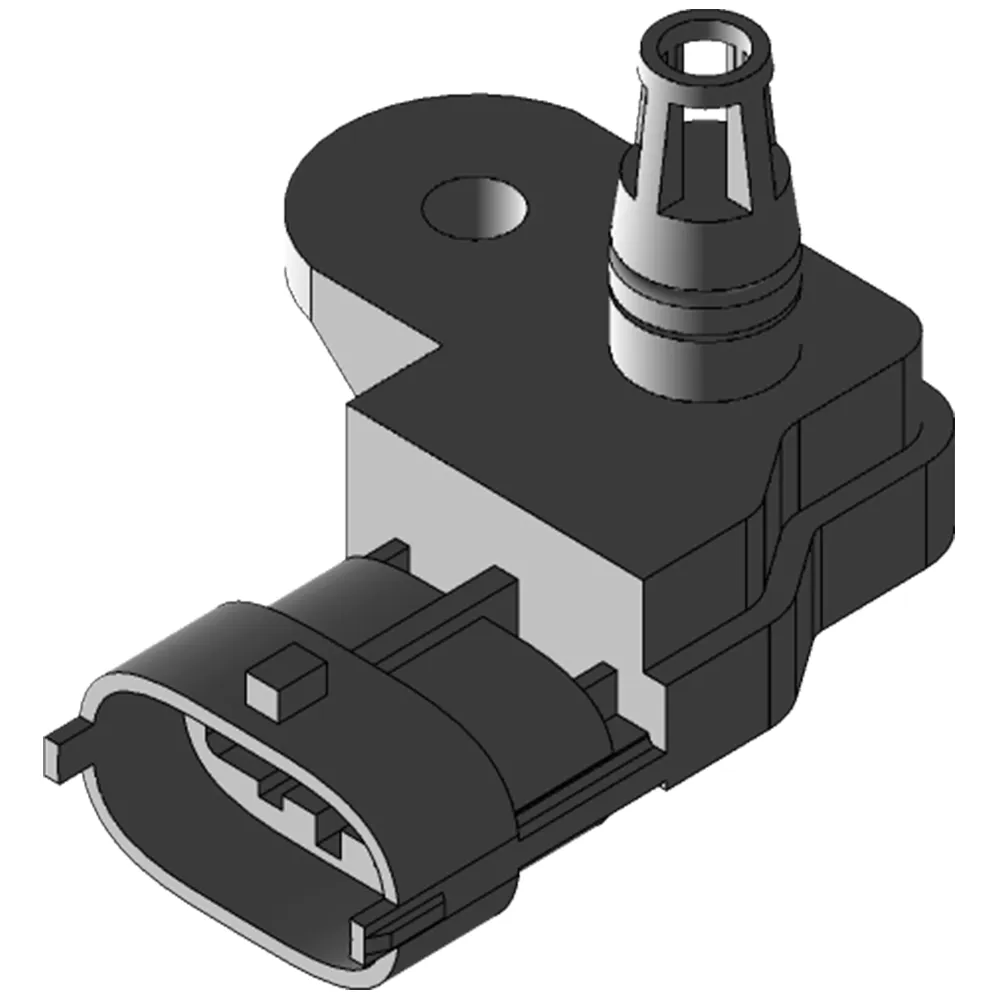

- Pre-SCR Sensing: Positioned upstream of the catalyst, this sensor provides real-time NOₓ levels to the engine control unit (ECU).

- Urea Injection Control: The ECU calculates the required urea volume based on the upstream NOₓ signal and dosing algorithms.

- Post-SCR Verification: A second NOₓ sensor downstream ensures that the catalyst effectively reduces NOₓ to harmless nitrogen (N₂) and water, while preventing ammonia slip.

This feedback loop is essential: too little urea leads to NOₓ exceedances, while too much causes ammonia emissions—both scenarios jeopardize compliance and engine performance.

3. Health, Environmental, and Regulatory Impact

By incorporating NOₓ sensors, manufacturers can meet stringent regulations such as Euro 7, EPA Tier 3, and China 7. Real-time NOₓ monitoring:

- Protects Public Health: Reduces smog-forming pollutants linked to asthma and cardiovascular diseases.

- Preserves Ecosystems: Limits acid rain, which damages soils, forests, and freshwater systems.

- Avoids Penalties: Ensures vehicles pass on-board diagnostics (OBD) and real-driving emissions (RDE) tests without costly recalls or fines.

4. Looking Ahead: Beyond Conventional NOₓ Sensing

Emerging trends include:

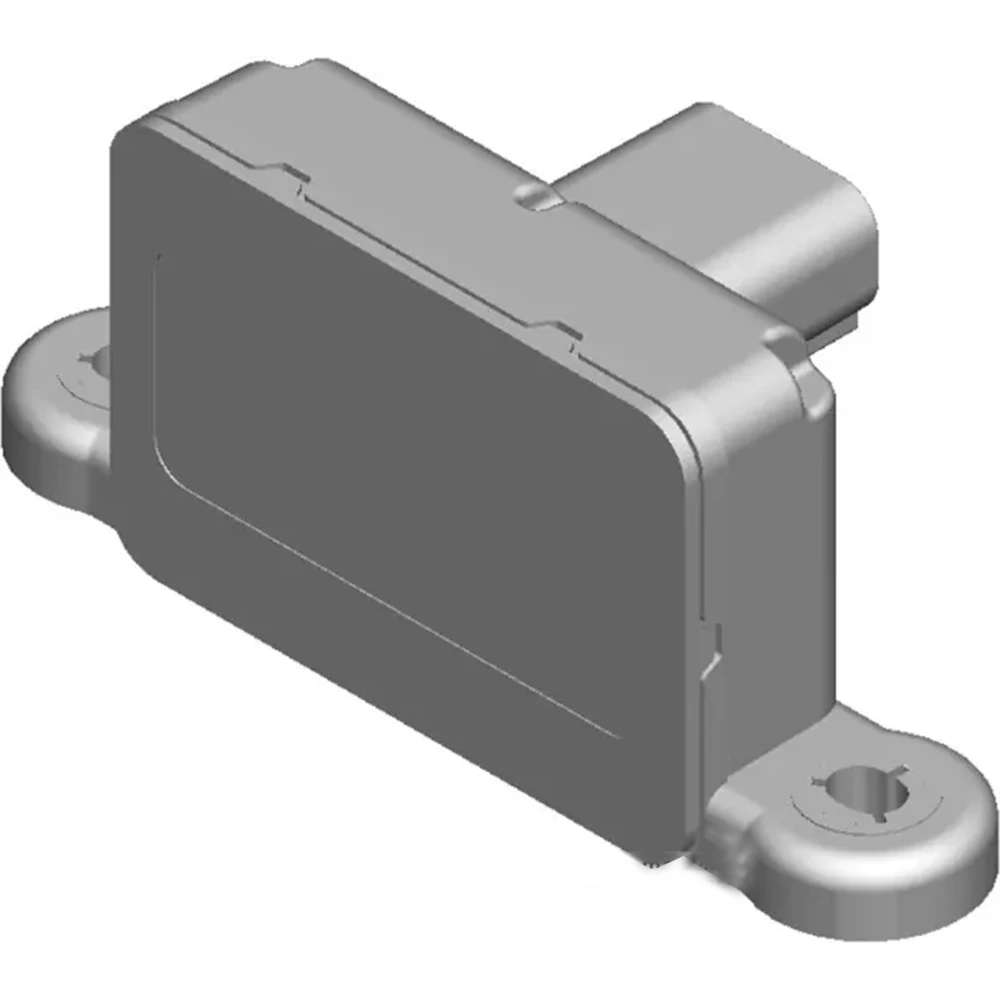

- Integrated Multi-Gas Modules: Combining NOₓ, O₂, and NH₃ sensors in one housing for streamlined installation and cost savings.

- IoT-Enabled Diagnostics: Cloud connectivity enables fleet managers to monitor NOₓ performance across thousands of vehicles, flagging outliers in real time.

- Advanced Materials: Research into low-power, nano-structured sensor films promises lower thermal budgets and faster response times.

NOₓ sensors are the linchpin of modern emission controls, bridging combustion chemistry and after-treatment effectiveness. As regulations tighten and technology evolves, these sensors will continue to drive cleaner, healthier, and more compliant mobility.