1. Emission Standards for NRMM

Non-road mobile machinery (NRMM) such as excavators, loaders, and generators must comply with Stage V in Europe and EPA Tier 4 in the U.S., which impose strict particulate limits. These standards drive the need for reliable PM monitoring to ensure continuous compliance.

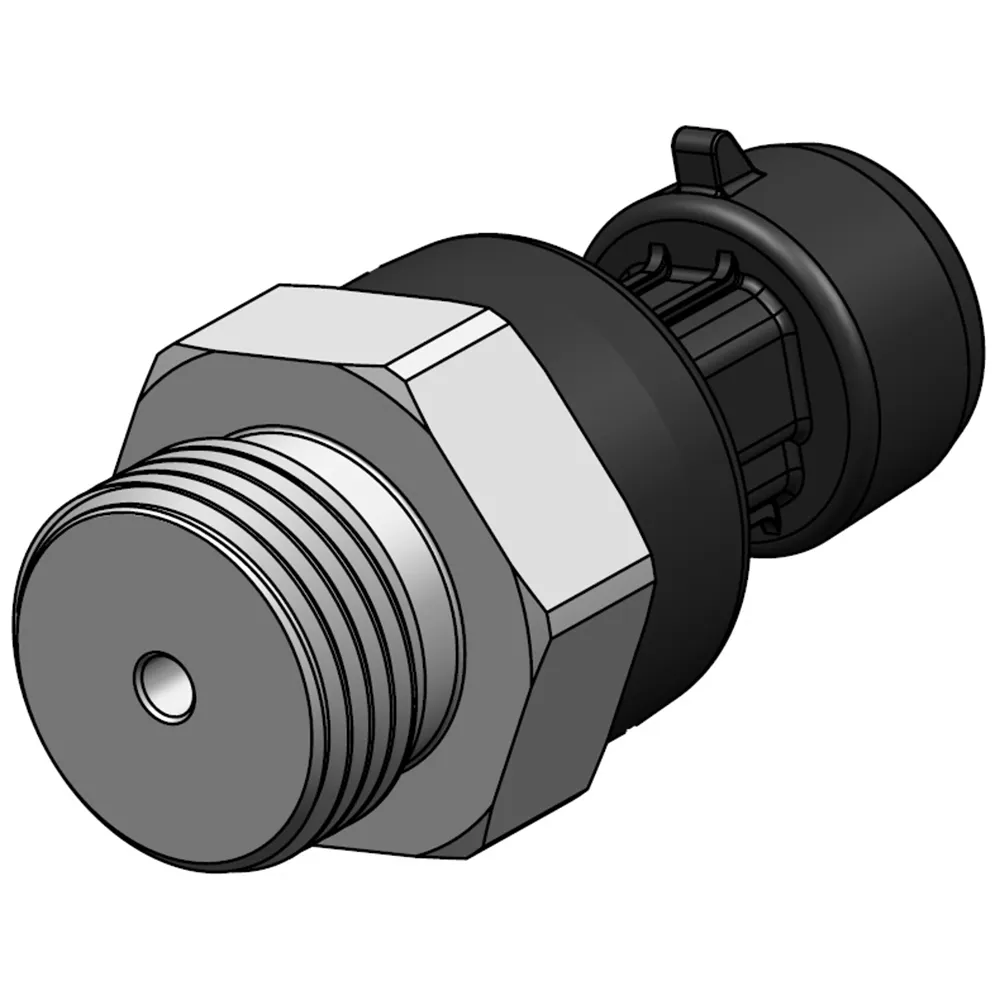

2. Vibration- and Heat-Resistant Sensor Design

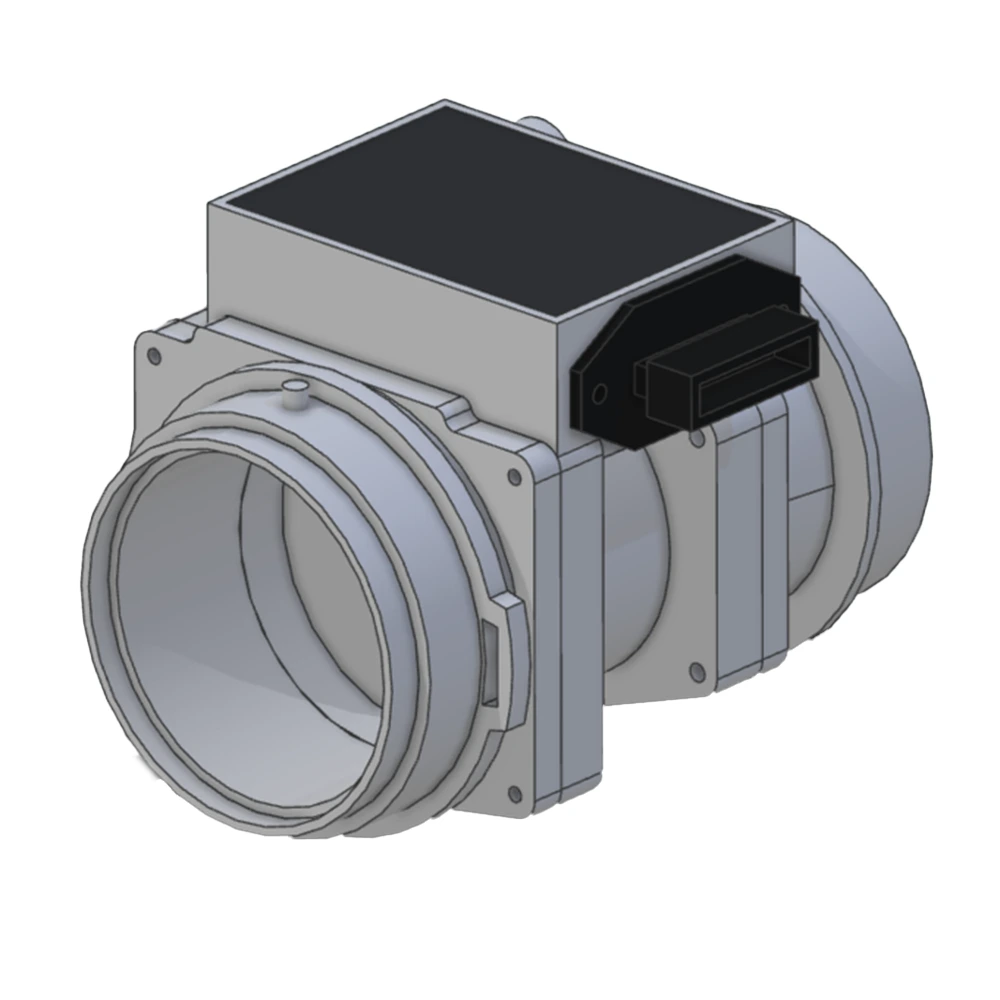

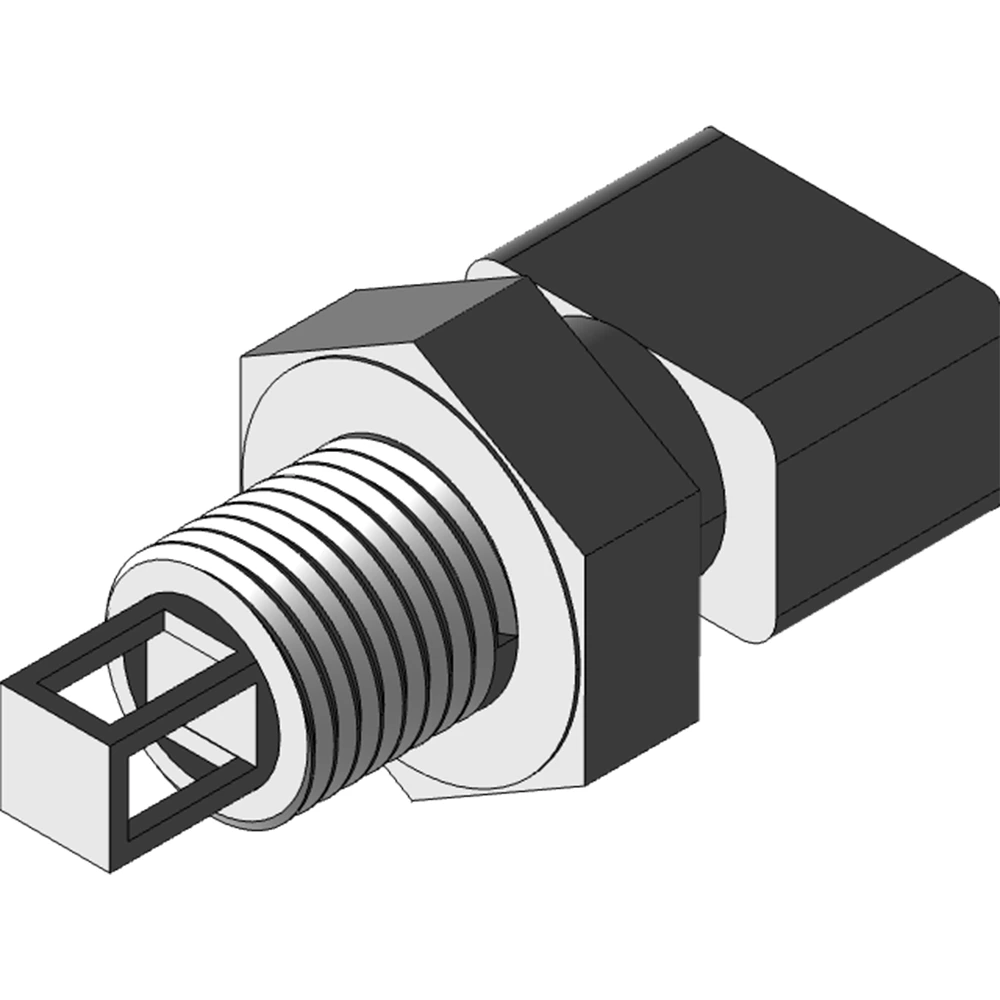

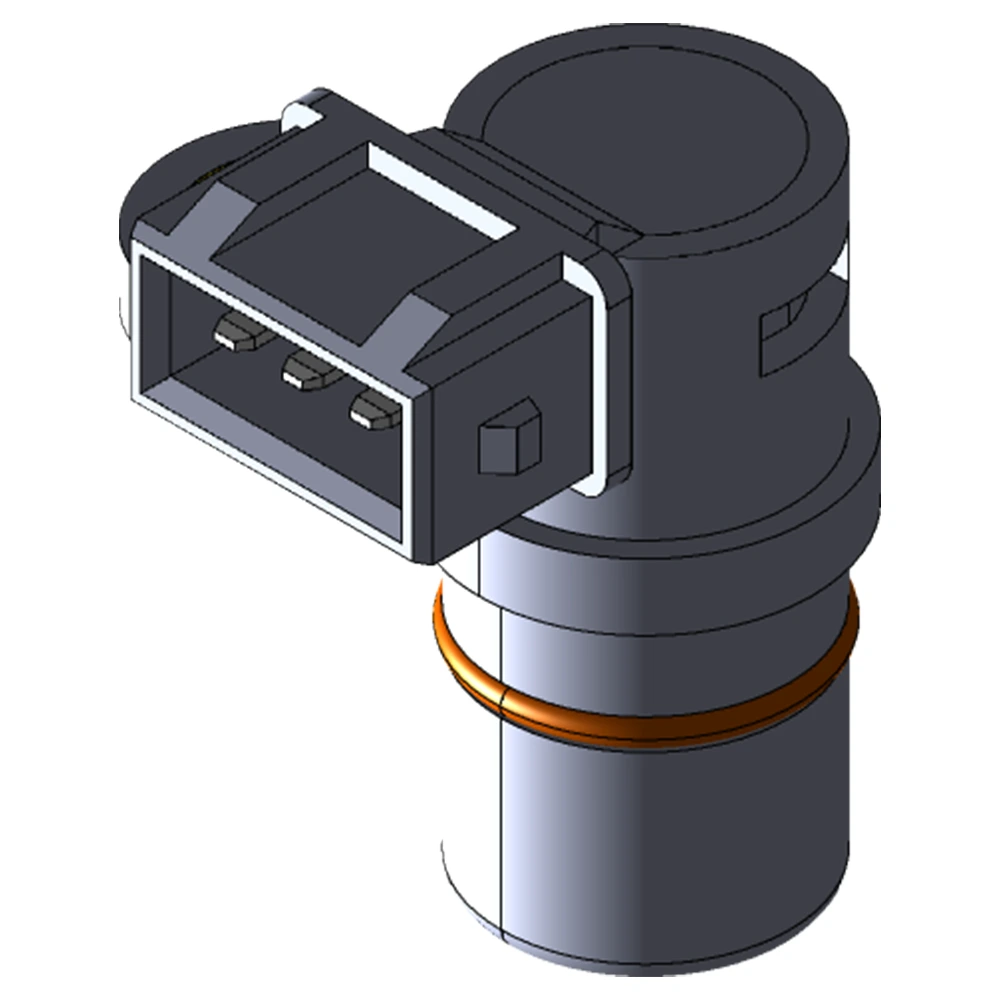

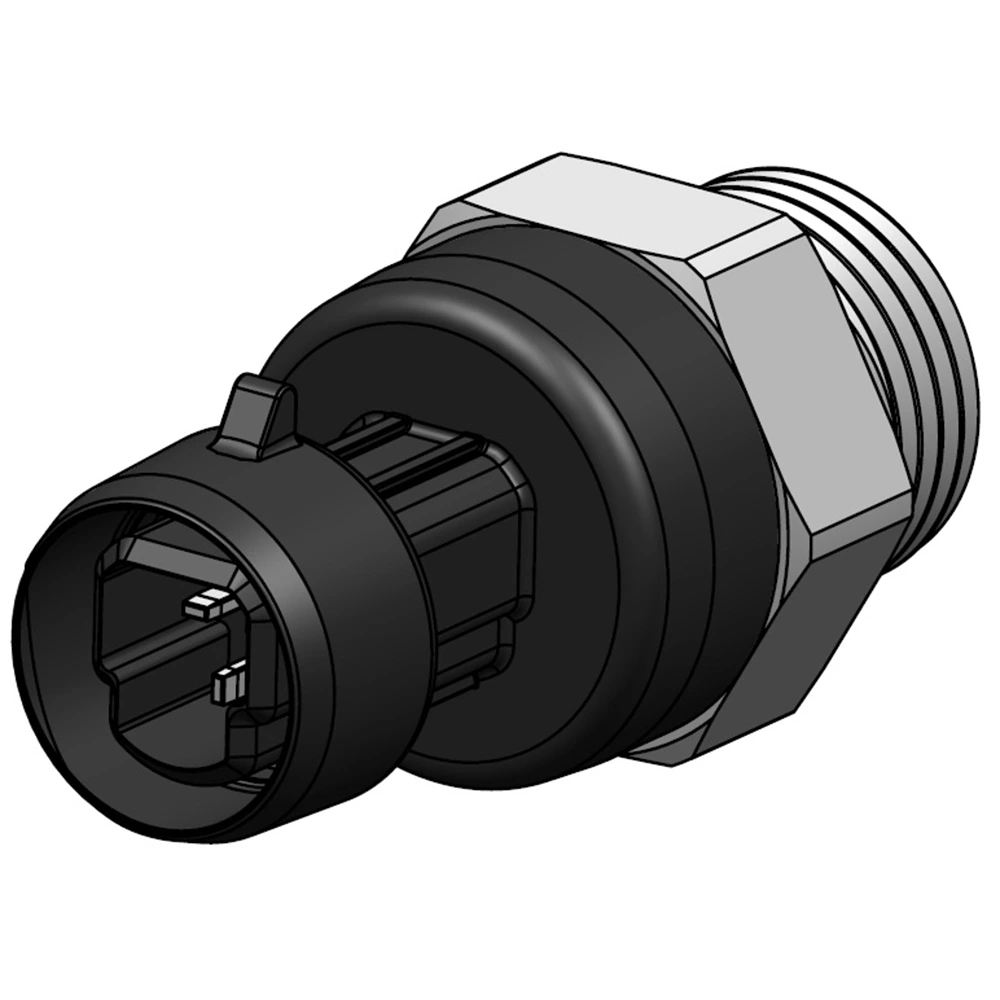

Construction sites present extreme conditions: constant vibration, dust, and high exhaust temperatures. Our rugged PM sensors feature reinforced housings, shock-absorbing mounts, and high-temperature electronics capable of operating reliably up to 900 °C.

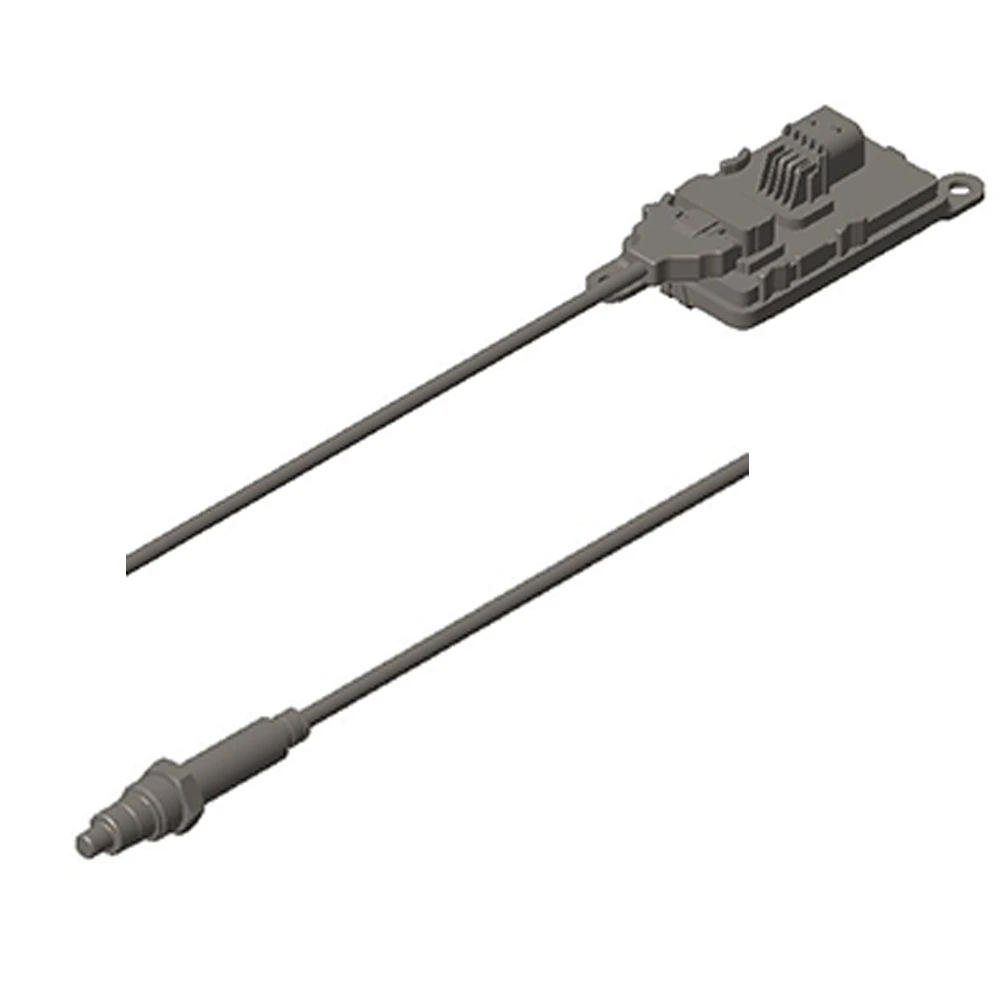

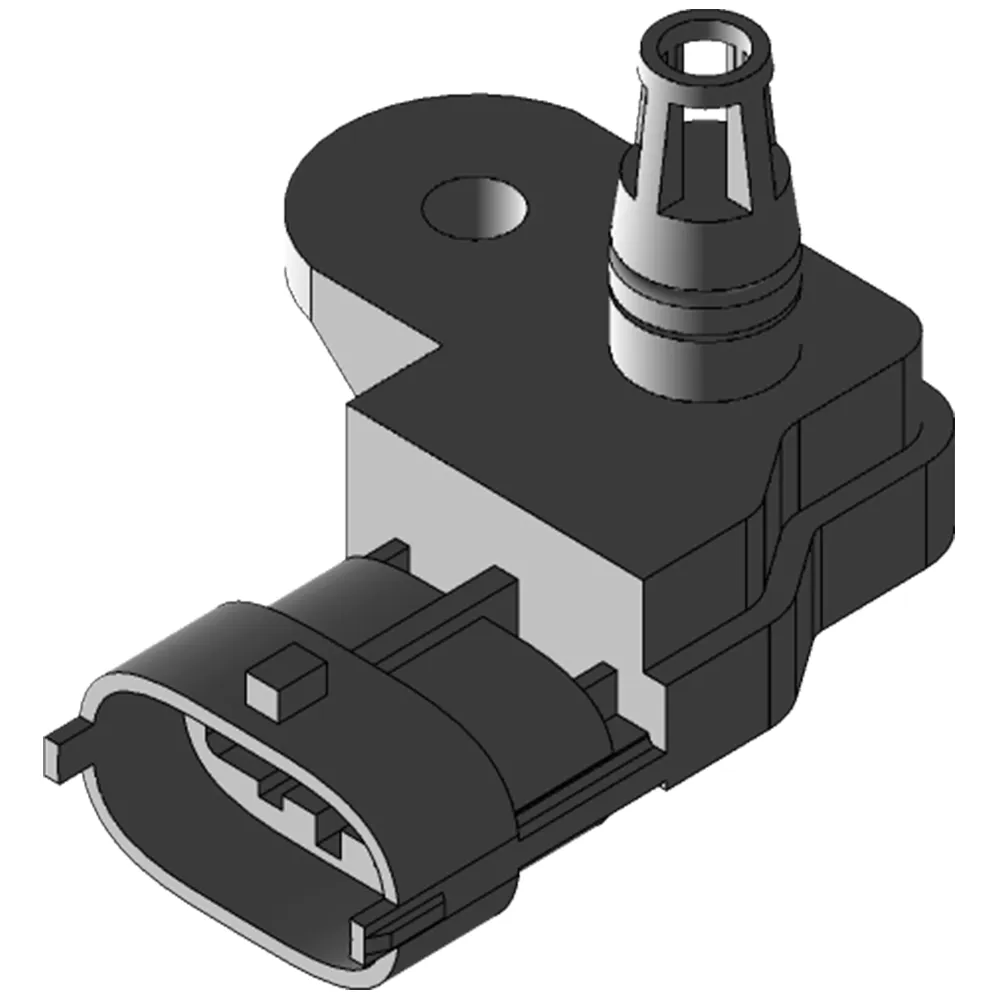

3. Connectivity with ECU and After-Treatment Systems

Seamless integration with existing ECUs is critical. Our sensors support CAN and analog outputs, allowing direct communication with DPF controllers and SCR units. Plug-and-play connectors simplify installation on diverse equipment platforms.

4. Improving Uptime and Maintenance

Real-time soot data helps schedule proactive DPF regeneration, reducing unplanned downtime. Fleets equipped with our sensors report a 20% decrease in service interventions and a 15% extension in filter life, translating into lower operating costs.

5. Real-World Deployment Cases

In a case study with a major mining fleet, retrofitting rugged PM sensors on 50 excavators led to compliance improvement and a 25% reduction in particulate emissions over six months. Operators also noted smoother regeneration cycles and improved fuel efficiency.

Conclusion

For off-highway and construction applications where reliability is non-negotiable, our rugged PM sensors deliver the accuracy and durability needed to meet the toughest emissions standards while maximizing equipment uptime.