1. Common PM Sensor Failure Modes

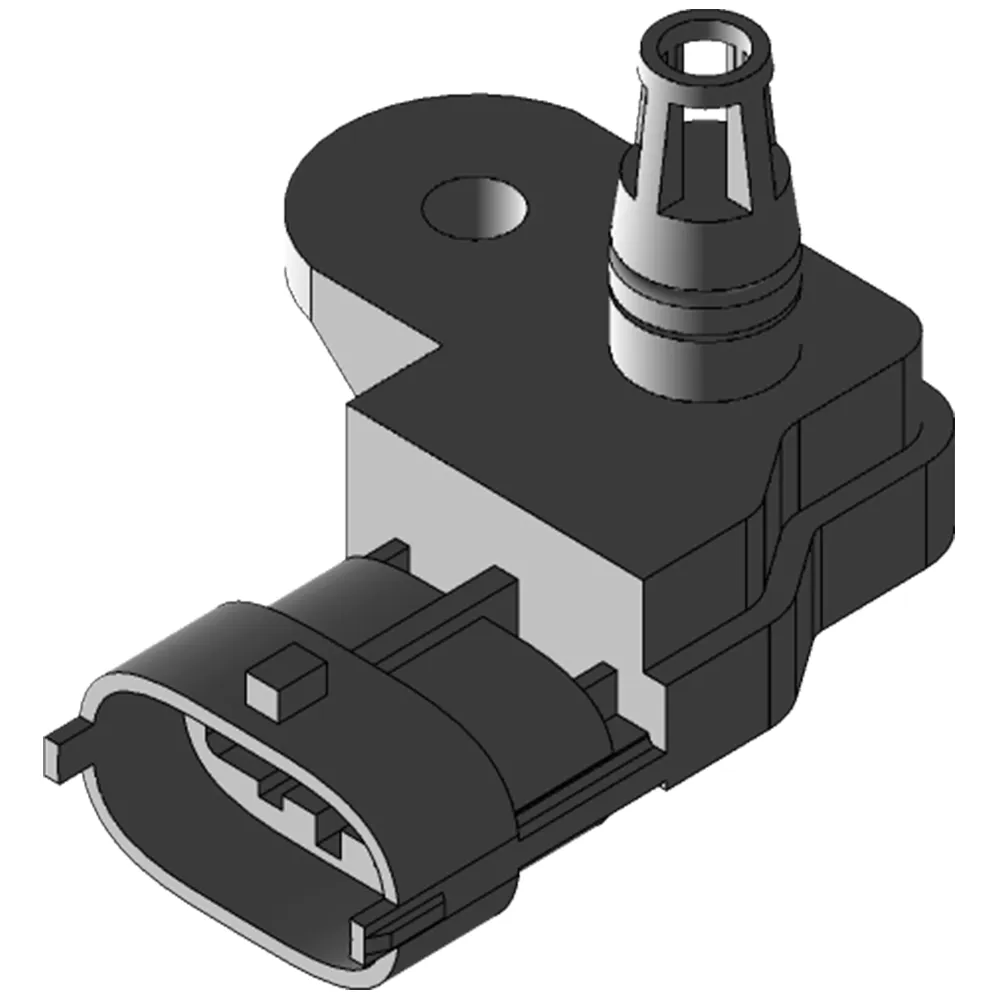

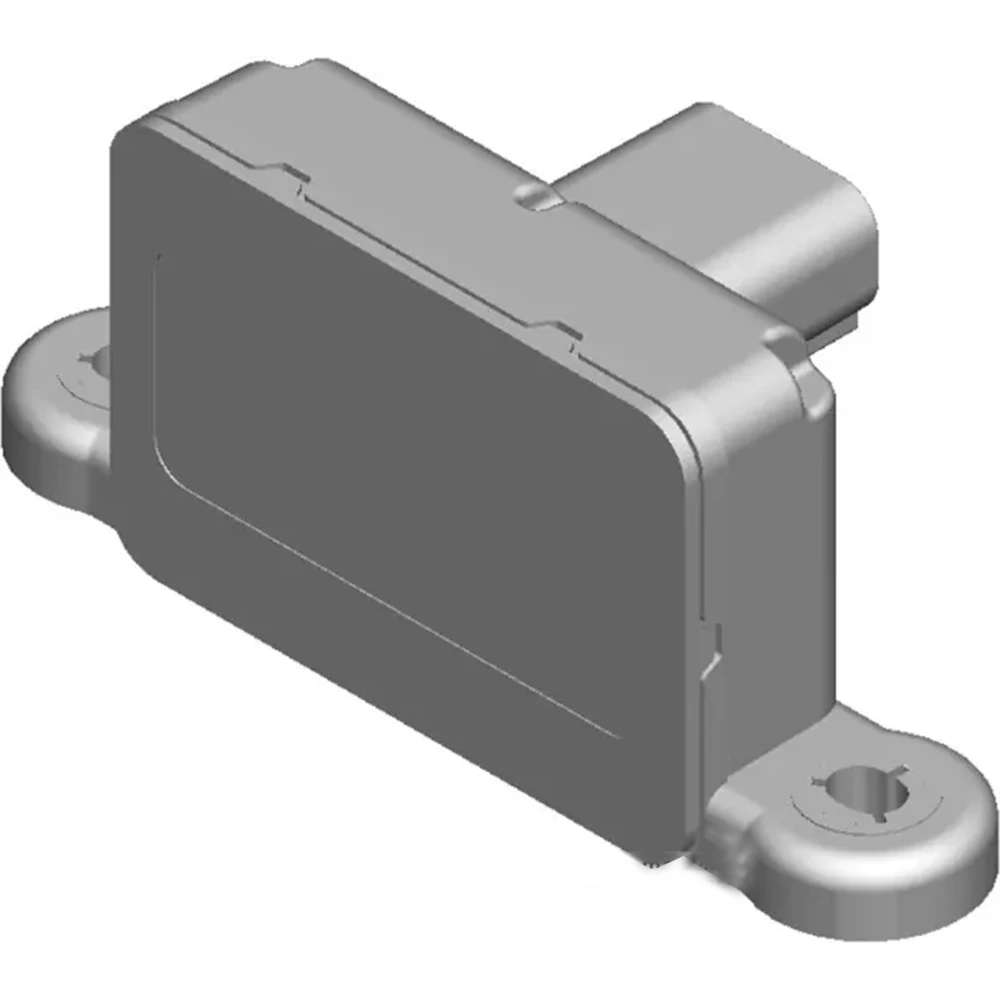

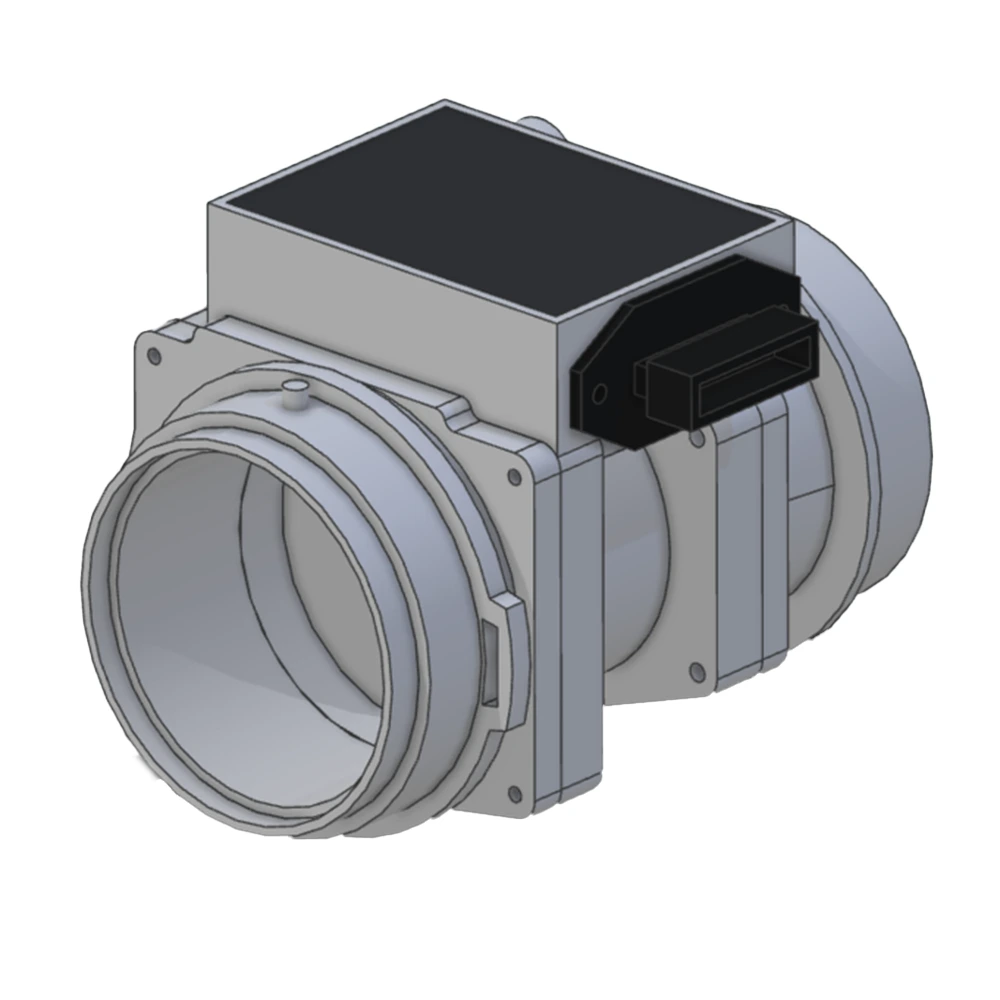

PM sensors can experience several types of failures, including:

- Fouling and clogging: Excess soot buildup on optical or resistive elements reduces sensitivity.

- Drift: Sensor baseline shifts over time due to thermal stress or contamination.

- Electronic faults: Wiring issues or connector corrosion leading to intermittent signals.

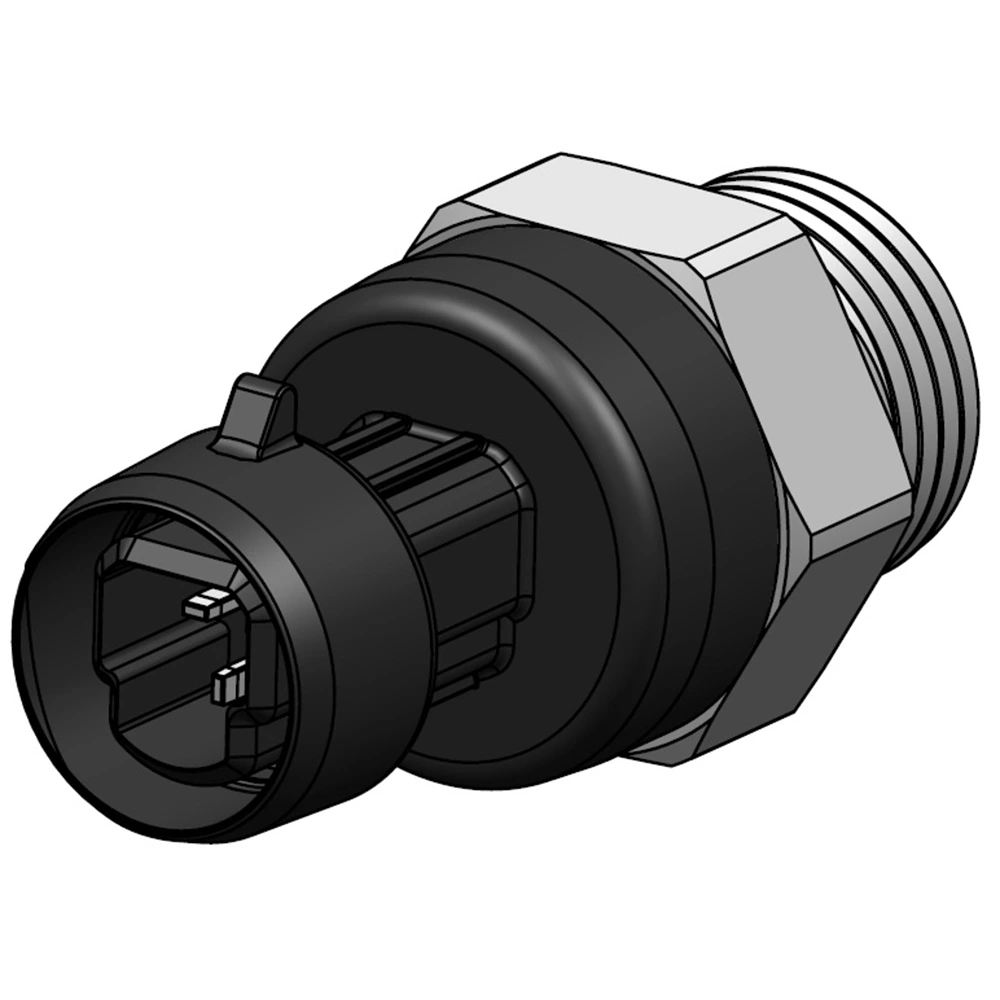

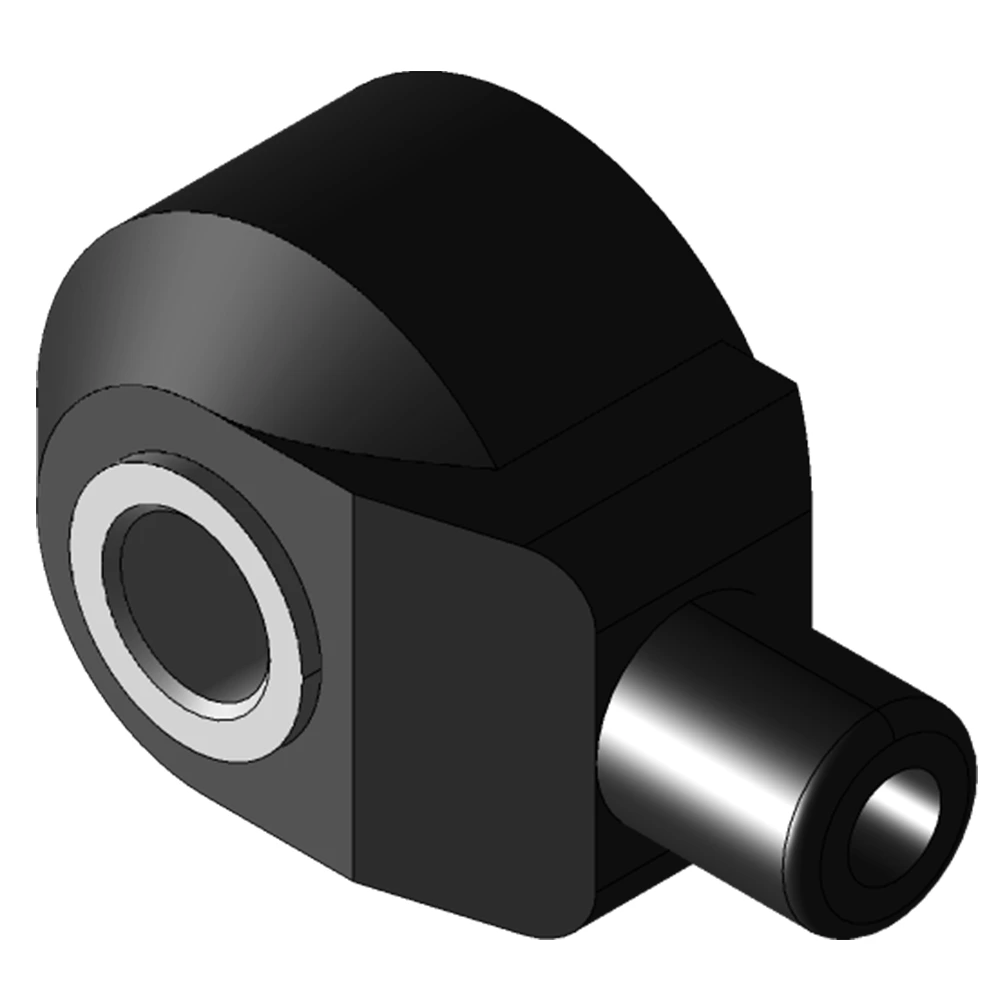

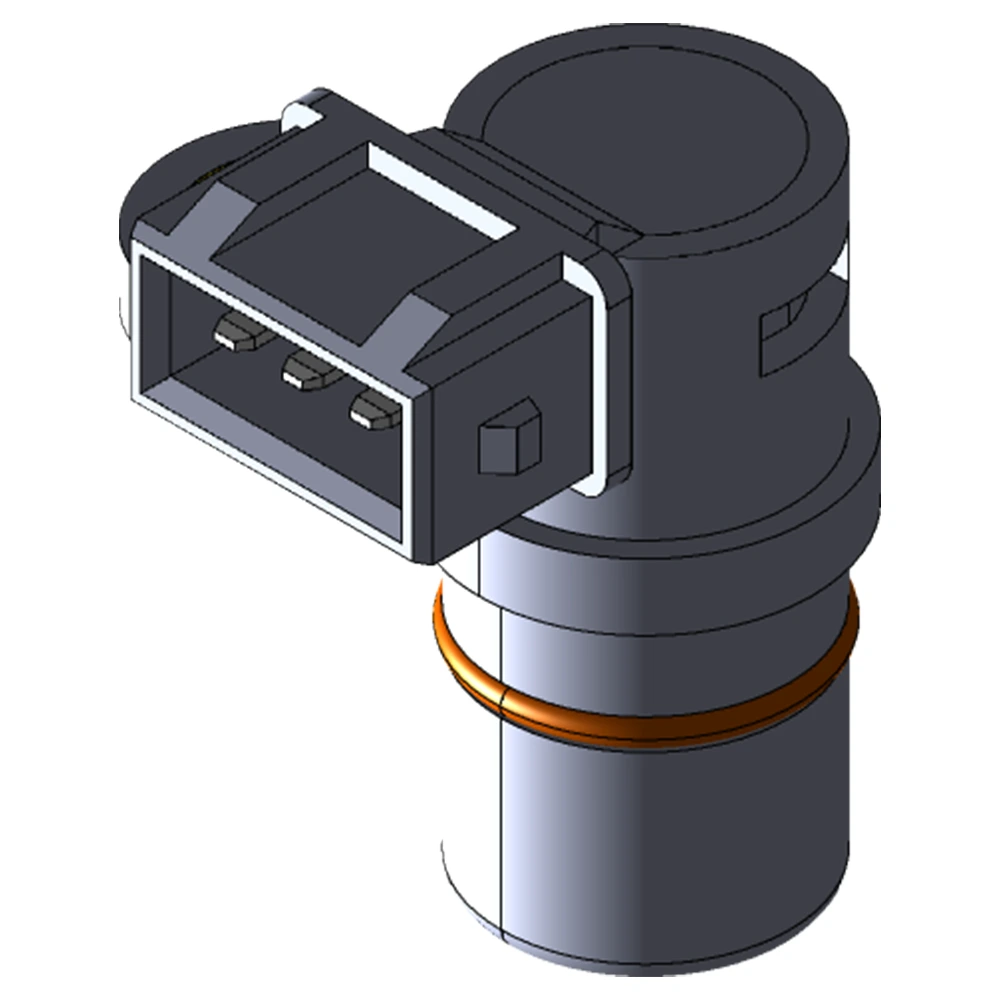

- Mechanical damage: Vibration-induced fractures in sensor housing or mounts.

2. Diagnostic Procedures Using OBD and Telematics

Start troubleshooting by retrieving diagnostic trouble codes (DTCs) via OBD-II or telematics platforms. Key steps include:

- Scan for PM-related codes (e.g., P24AF for DPF pressure sensor irregularities).

- Monitor live data to observe PM concentration trends and identify anomalies.

- Compare pre- and post-DPF readings to detect delta discrepancies indicative of sensor drift.

3. Cleaning and Recalibration Techniques

- Optical sensors: Use controlled air blasts or isopropyl alcohol swabs to clear lens surfaces. Avoid harsh solvents that may damage coatings.

- Resistive sensors: Implement in-situ regeneration cycles at elevated exhaust temperatures to burn off accumulated soot.

- Recalibration: Utilize OEM or aftermarket calibration tools to reset sensor baselines, ensuring accurate readings post-cleaning.

4. Preventive Maintenance Best Practices

- Schedule routine inspections: Align with DPF service intervals to minimize unexpected failures.

- Monitor environmental conditions: High sulfur fuels or heavy idling can accelerate sensor fouling.

- Ensure proper grounding and shielding: Prevent electrical noise from corrupting sensor signals.

- Update firmware: Apply sensor firmware updates to benefit from improved drift compensation and self-test algorithms.

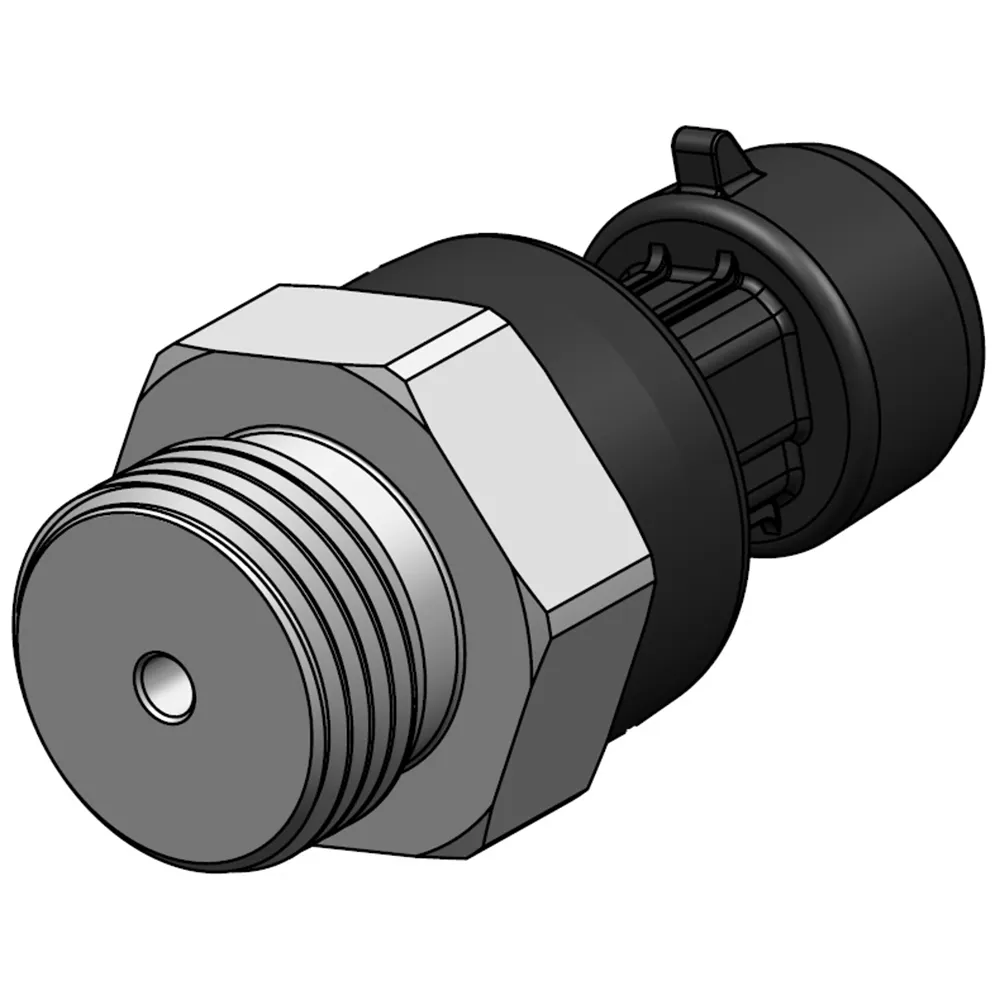

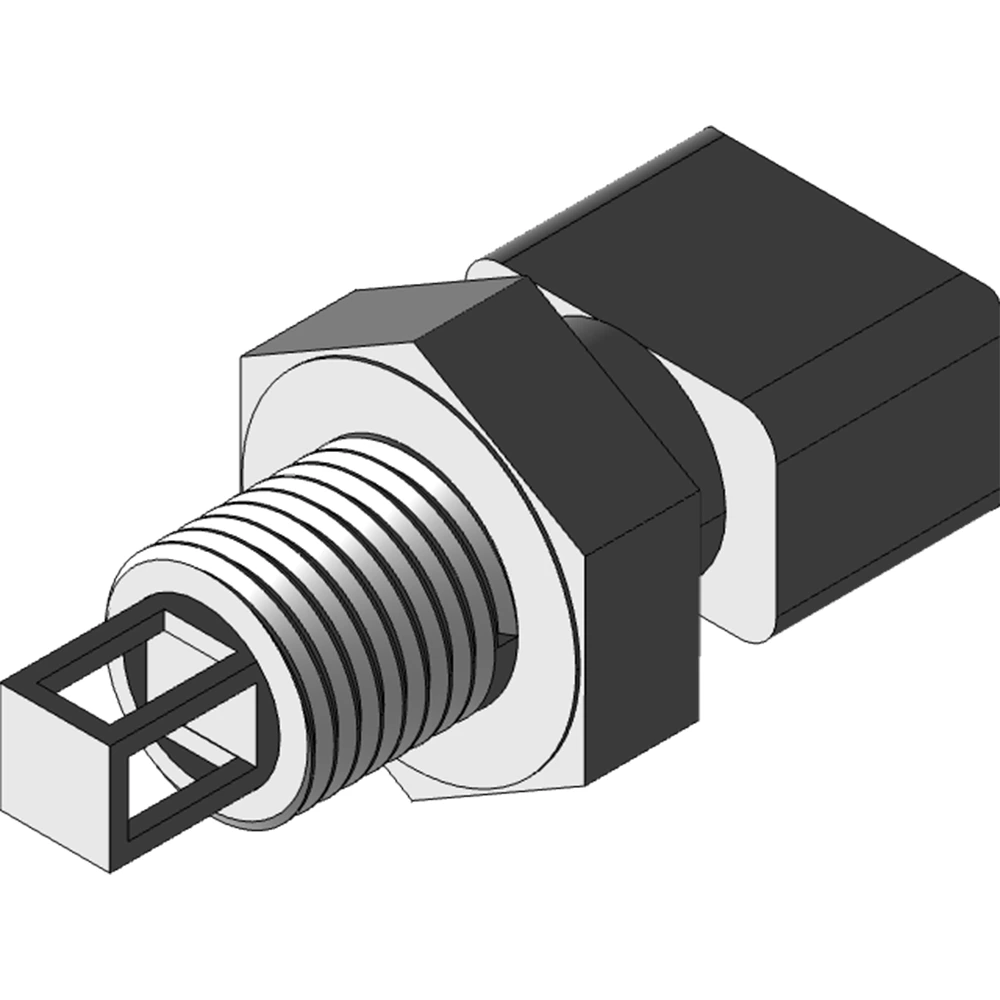

5. When to Replace a PM Sensor

Despite best practices, sensors may reach end-of-life. Consider replacement when:

- Persistent error codes reappear after cleaning and recalibration.

- Response time degrades beyond manufacturer specifications.

- Physical damage compromises sensor integrity.

- Firmware upgrades are incompatible with legacy hardware.

Effective troubleshooting and maintenance of PM sensors are critical to sustaining emission compliance and vehicle uptime. By understanding common failure modes and implementing proactive care, user can extend sensor life, reduce repair costs, and ensure accurate particulate monitoring for years to come.