Turbocharger – How it works & failed?

A key difference between a turbocharged diesel engine and a traditional naturally aspirated gasoline engine is that the air entering the diesel engine is compressed before the fuel is injected. Here, the turbocharger is critical to the power and efficiency of the diesel engine.

The function of the turbocharger is to compress more air flowing into the engine cylinder. When air is compressed, the oxygen molecules are packed closer together. This increase in air volume means more fuel can be added for the same size engine. Mechanical power is then increased and the overall efficiency of the combustion process is improved. Therefore, a turbocharged engine can be downsized, resulting in better packaging, weight savings and overall fuel economy.

How a turbo work?

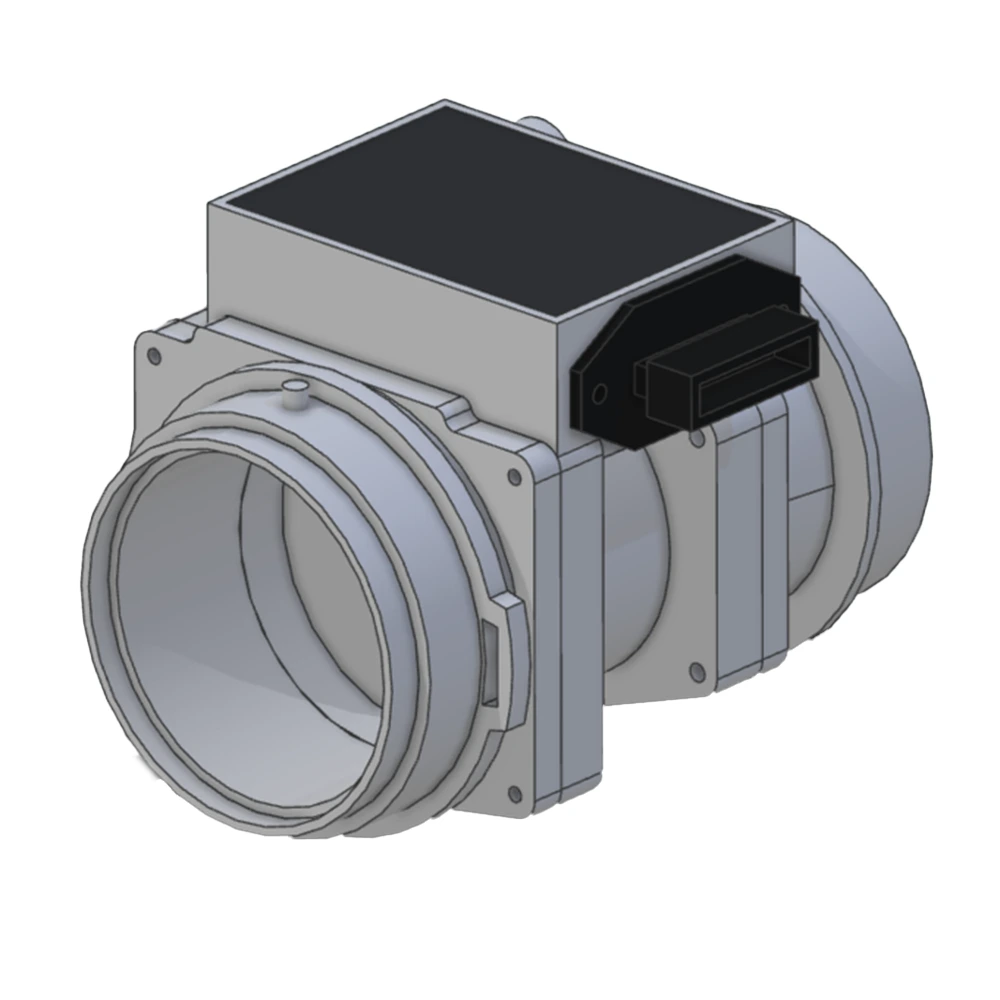

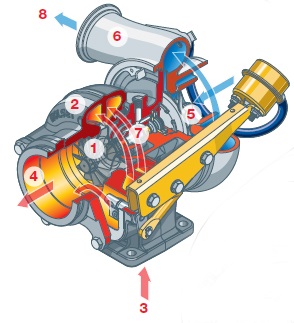

A turbocharger consists of two main sections: a turbine and a compressor. The turbine consists of a turbine wheel (1) and a turbine housing (2). The function of the turbine housing is to direct the exhaust gas (3) into the turbine wheel. The energy from the exhaust turns the turbine wheel and the gas then exits the turbine housing through the exhaust outlet (4).

The compressor also consists of two parts: the compressor wheel (5) and the compressor housing (6). The mode of operation of the compressor is opposite to that of the turbine. The compressor wheel is attached to the turbine by a forged steel shaft (7) and as the turbine rotates the compressor wheel, the rapid rotation draws in and compresses air. The compressor housing then converts the high-velocity, low-pressure airflow into a high-pressure, low-velocity airflow by diffusion. Compressed air (8) is forced into the engine, allowing the engine to burn more fuel to produce more power.

Why a turbo failed?

Less than 1% of turbos fail because of manufacturing defects. Most failures are caused by the three ‘turbo killers’ of oil starvation, oil contamination and foreign object damage.

More than 90% of turbocharger failures are caused oil related either by oil starvation or oil contamination. Blocked or leaking pipes or lack of priming on fitting usually causes oil starvation.

Other reasons, such as bad driving habits, can cause turbo failure, so you should also consider the following reasons:

- Prolonged engine idling can create a vacuum with the turbine

- Cold acceleration does not give the oil time to circulate, causing oil retention in the turbo and engine bearings.

- Hot engine shutdown can cause carbon build-up in the turbo, leading to bearing failure.

- Especially in commercial vehicles such as highway trucks, revving the engine beyond the safe limit can cause turbo overspeed and excessive engine boost (this can also happen with naturally aspirated engines) and suffer from oil light.

Common turbocharger error codes

A turbocharger offers numerous benefits; it plays an instrumental role in increasing horsepower and the overall efficiency of a vehicle. In a nutshell, it makes use of the used exhaust gases and ensures that it passes through the turbo. The production of additional air from the turbo then gets pushed into the cylinder that allows for more fuel to be burnt. Hence, if you want to ensure the optimum performance of your car, it is of paramount importance for you ensure that your turbo is in pristine condition at all times.

Common error codes for turbo problems:

- P0045: Turbo/Super Charger Boost Control Solenoid Circuit/Open.

- P2262: Turbo Boost Pressure Not Detected-Mechanical.

- P0234: Turbocharger Overboost Condition.

- P0299: Underboost condition

Symptoms of turbocharger faulty

- Black smoke

- Blue smoke

- Turbocharger generates acoustic noise

- Boost pressure too high

- Compressor/turbine wheel defective

- Oil leakage at turbine

- High oil consumption

- Insufficient power/boost pressure too low

- Oil leakage at compressor

For details, pls see Failure Symptoms and Possible Causes

Troubleshooting a fault turbocharger

If the engine does not operate properly, one should not assume that the turbocharger is the cause of failure. It often happens that fully functioning turbochargers are replaced even though the failure does not lie here, but with the engine.

Only after all these points have been checked should one check the turbocharger for faults. Since the turbocharger components are manufactured on high-precision machines to close tolerances and the wheels rotate up to 300,000 rpm, turbochargers should be inspected by qualified specialists only.

How to replace a faulty turbocharger

TURBO Installation, the following steps must be followed strictly.

Consult your workshop manual for engine-specific instructions.

Make sure the correct gaskets are used for installation.

The center hole of the oil supply seal must be aligned with the center hole of the mounting flange.

Note: DO NOT use gasketed liquid seal for oil supply or drain. Seals can enter the turbo oil supply and reduce or block oil flow, causing turbocharger failure.

- Replace the air, oil and fuel filters with original parts. Remove and replace the engine oil with the correct grade of oil according to the manufacturer’s specifications.

- Check that all turbocharger air hoses are clean and intact with no perforations.

- The air filter and air cleaner housing must be thoroughly inspected and free of foreign objects.

- Check and clean the engine breather. If the ventilation hose has collapsed internally, replace it accordingly.

- Before installing the turbocharger, remove the old gasket material from the exhaust manifold and oil flange fittings.

- Oil supply and drain lines must be completely clean and undamaged to ensure unrestricted oil flow.

Check the oil drain hoses internally, if the hose has collapsed internally, replace the hose. Check that the oil supply line is not damaged or placed too close to a heat source that could damage the oil supply line internally (this is a common problem on various vehicles and difficult to detect without cutting the line to check internally).

We highly recommend replacing the oil sump with the installation of a replacement turbocharger as noted above.

Get Full Support

MOOCAR — as a leading exporter, we are continually developing breakthrough sensing and actuating solutions to help optimize emissions control, fuel economy, and drivability. In addition to the above parts, we offer full support of data, market information.